As electrical systems become more advanced, the demand for more reliable, durable, and efficient components grows. Connectors Terminals—including TB TC TD Terminal—is at the forefront of this evolution, constantly evolving to meet the ever-changing needs of industries worldwide. Technological advancements in these terminals have led to innovations that improve both their performance and longevity, helping electrical systems run smoothly and efficiently.

1. The Evolution of Connectors Terminals

Over the years, Connectors Terminals have undergone significant improvements in design, material selection, and manufacturing processes. These innovations address key challenges in the electrical industry, such as safety, durability, and ease of installation.

Design Improvements

Early Connectors Terminals were relatively simple, offering basic functionality but lacking advanced features for safety and performance. However, with the rise of high-demand industries such as power distribution, automotive, and telecommunications, the need for more robust and versatile terminals became apparent.

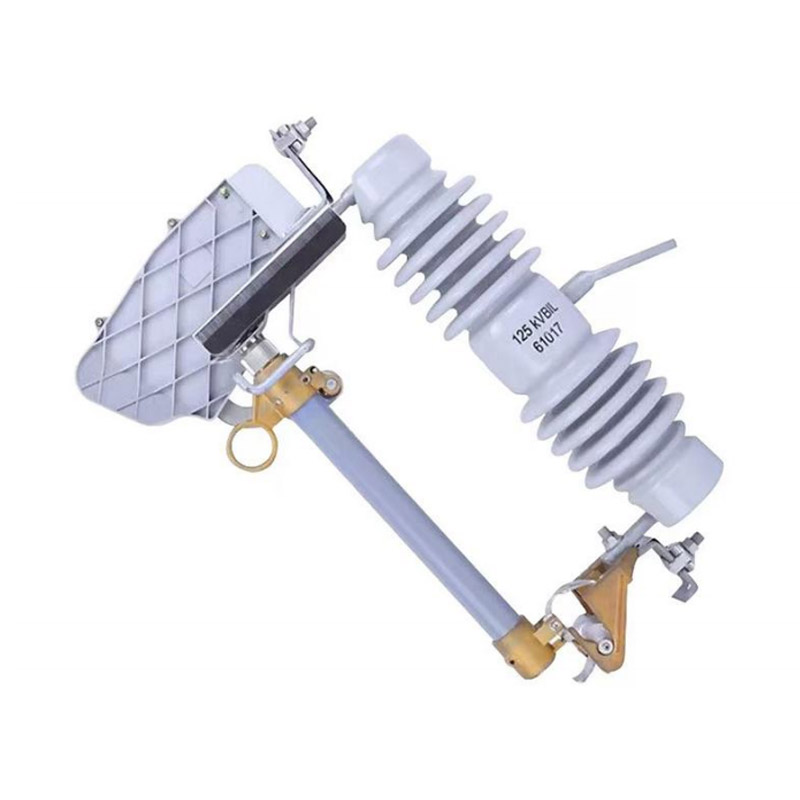

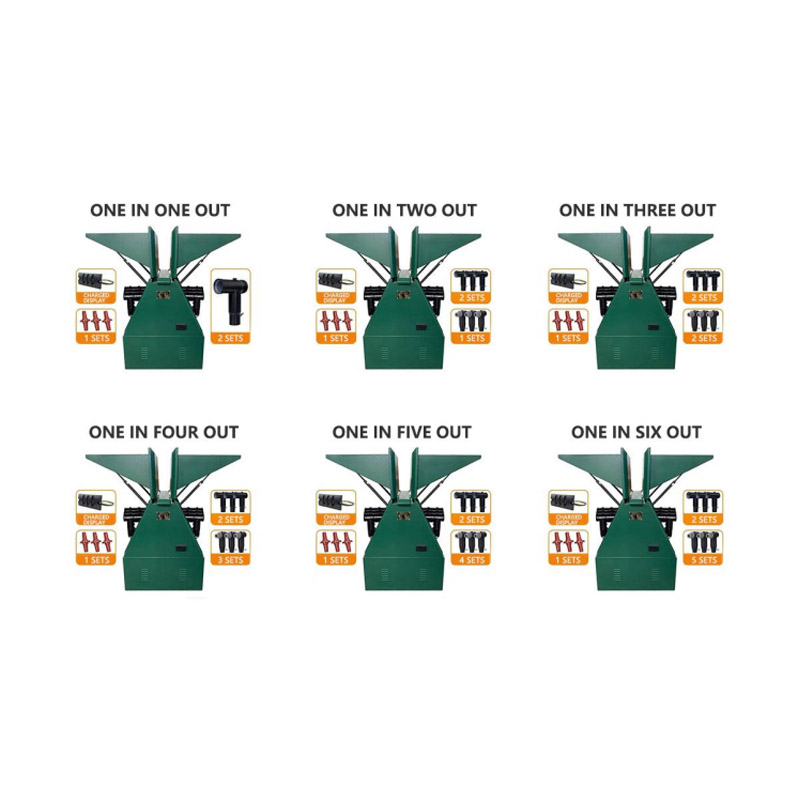

Today’s TB TC TD Terminals feature advanced designs that maximize efficiency while minimizing space and weight. For example, TB Terminals are now optimized for high-current applications with reinforced structures to handle larger electrical loads. TC Terminals have evolved to offer compact designs that still provide strong connections, making them ideal for use in small, space-constrained devices like circuit boards and consumer electronics. Similarly, TD Terminals have been adapted to be more flexible, with customizable configurations that accommodate a wide range of wire sizes and connection types.

Material Advancements

Materials used in Connectors Terminals have also evolved significantly. Modern terminals are made from high-performance alloys that offer outstanding electrical conductivity, corrosion resistance, and heat resistance. For instance, TB TC TD Terminals are often made from materials like copper, tin-plated copper, and stainless steel, which enhance the terminal's lifespan, especially in harsh environments.

These material advancements help ensure that Connectors Terminals maintain their performance even in excessive temperatures, high humidity, or other challenging conditions.

2. Smart Features in Modern TB TC TD Terminals

The integration of smart features into Connectors Terminals is another exciting area of innovation. As the electrical industry moves towards smart grids, Internet of Things (IoT) applications, and automation, connectors are becoming increasingly sophisticated.

Enhanced Safety Features

Safety is a top priority in electrical systems, and TB TC TD Terminals now come equipped with enhanced safety features to prevent electrical accidents. These terminals often include:

Locking Mechanisms: Many modern terminals now feature built-in locking mechanisms that prevent accidental disconnections, ensuring a more stable and secure connection.

Insulation: Improved insulation materials provide better protection against electric shocks and short circuits, especially in environments where wires are exposed to moisture or high temperatures.

Integrated Monitoring Systems

Some advanced TB TC TD Terminals are designed to work with integrated monitoring systems, providing real-time data on the health of the electrical connection. These terminals can detect issues like overheating, loose connections, or signs of wear, alerting operators to potential problems before they escalate.

For example, Connectors Terminals with built-in sensors can monitor voltage, current, and temperature levels, sending data to a central monitoring system. This capability is especially useful in industrial applications where early detection of faults can prevent costly downtime and equipment damage.

Contact us today to learn more about our products and how we can support your next project with our innovative and reliable Connectors Terminals.

English

English Español

Español عربى

عربى