Ensuring that connector terminals are properly installed is critical for the long-term performance and reliability of any electrical system. Whether you are working with TB TC TD Terminal or other types, correct installation is essential to prevent issues such as loose connections, overheating, or electrical failures. A properly installed terminal guarantees the safety, efficiency, and durability of your system.

1. Preparing for Installation of Connectors Terminals

Before beginning the installation of Connectors Terminals, proper preparation is key to ensuring a smooth and efficient process. The following steps are critical in ensuring that you set yourself up for success:

Select the Right Terminal

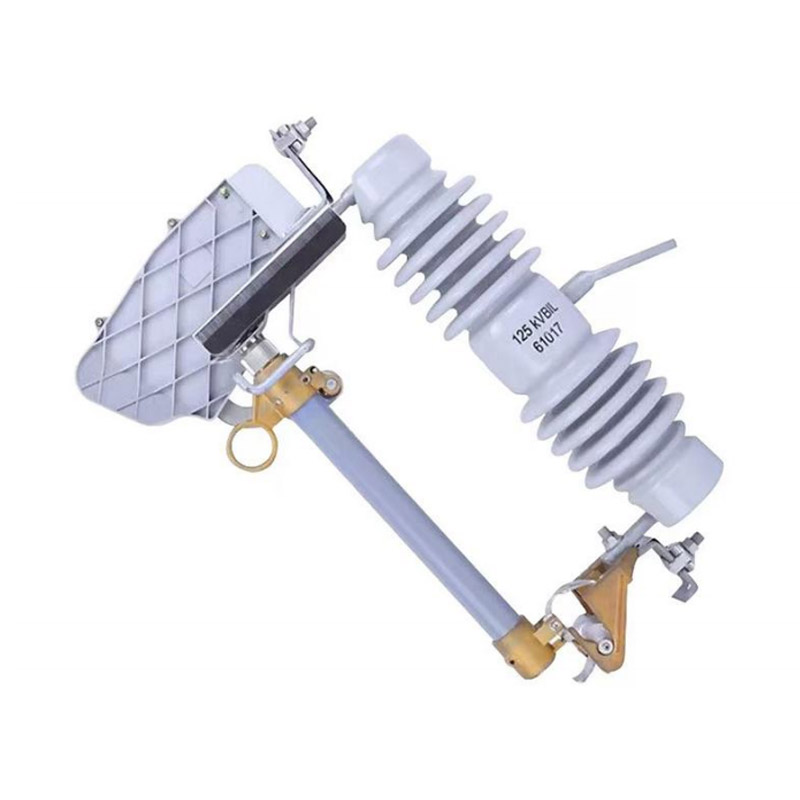

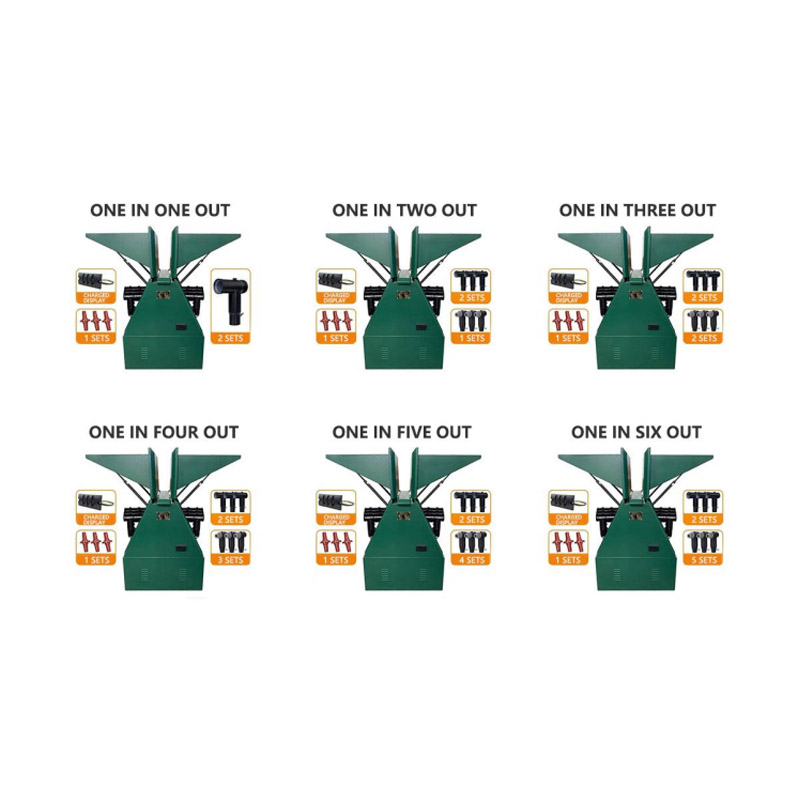

Choosing the correct Connectors Terminals is the initial step in the installation process. As mentioned previously, TB TC TD Terminals each have unique features and are suited for different applications. Be sure to select the terminal that matches the voltage, current, and environmental conditions of your project.

Gather the Necessary Tools

Installing Connectors Terminals requires the right tools to ensure a secure connection. You’ll need tools such as:

Wire Strippers: To remove the insulation from the wires without damaging the copper core.

Crimping Tools: For applying pressure to the terminal, ensuring a tight fit and solid connection.

Insulation Tape: To cover and protect exposed areas once the terminal is installed.

Having the correct tools on hand will make the installation process faster and ensure that connections are safe and reliable.

Check for Compatibility

Before installation, verify that the terminal is compatible with the wire gauge you are using. TB TC TD Terminals come in various sizes to accommodate different wire types. Ensuring compatibility prevents improper fittings and maintains a secure connection.

2. Step-by-Step Guide to Installing TB TC TD Terminals

Step 1: Prepare the Wire

To install Connectors Terminals effectively, you must initial prepare the wire. Use a wire stripper to remove the insulation from the end of the wire, exposing the copper core. The length of the exposed wire should match the length of the terminal's contact area, ensuring a solid electrical connection.

Step 2: Insert the Wire into the Terminal

Insert the stripped wire into the terminal's wire entry point, making sure that the copper wire makes direct contact with the metal terminal. For TB TC TD Terminals, this step is crucial to avoid any loose connections, which could cause to arcing or overheating.

Step 3: Crimp the Terminal

Using a crimping tool, apply pressure to the terminal to secure the wire in place. This step is essential for ensuring that the terminal grips the wire firmly, which will provide a reliable electrical connection. Be careful not to over-crimp, as this can damage the terminal or wire.

Step 4: Insulate and Protect

Once the terminal is securely crimped, it’s important to insulate and protect the connection. Use electrical insulation tape or heat shrink tubing to cover the exposed areas of the wire and terminal. This step is vital to prevent short circuits and ensure the longevity of the connection.

Step 5: Test the Connection

After installing the terminal, it’s important to test the connection to make sure it is working as expected. Use a multimeter to check for continuity and ensure there are no loose connections or electrical faults.

At Zhejiang Haidu Electric Co., Ltd., we are dedicated to providing high-quality Connectors Terminals that meet the needs of our customers. With our advanced manufacturing processes, rigorous testing, and customized solutions, we offer products that deliver outstanding performance in every application. Contact us today to learn more about our TB TC TD Terminals and how they can improve the performance of your electrical systems.

English

English Español

Español عربى

عربى