Using the right junction box and circuit breaker block junction box can bring more than safety — it can significantly improve installation efficiency, reduce long-term costs, and help meet regulatory requirements. In many industrial, commercial, and infrastructure projects, inefficiencies or non-compliance around wiring enclosures add hidden costs and risk.

Efficiency Gains: How Better Enclosures Help

Reducing Labor and Installation Time

When installers work with well-designed junction box solutions and circuit breaker block junction box systems that are sized appropriately, pre-mounted, or modular, they spend less time fitting wires, making terminations, and troubleshooting. For example:

Enclosures with pre-punched or knock-out entries speed up cable routing.

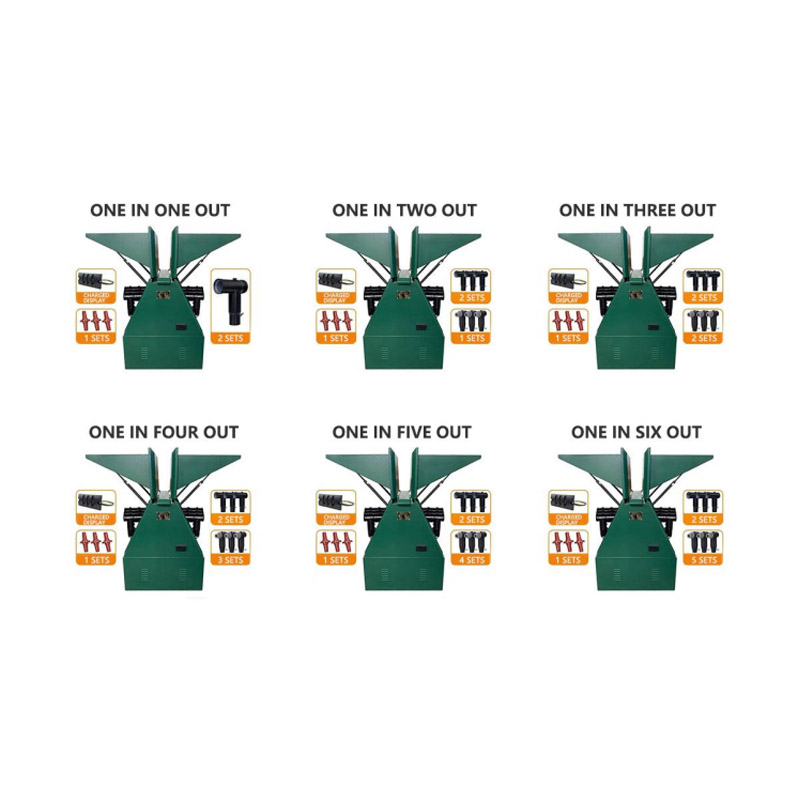

Modular breaker block systems reduce the need for custom mounting or fabricating support frames.

Components such as cable glands and built-in strain reliefs reduce extra steps.

These factors help reduce labor hours, which often account for large portions of total project costs.

Lower Maintenance and Downtime

Well-chosen junction boxes and circuit breaker block junction boxes reduce future maintenance. Reasons include:

Better protection against moisture, dust, or corrosion reduces degradation of terminals.

Proper box fill and conductor spacing reduce heating issues that may otherwise require repair.

Accessible designs make inspection, re-torqueing, or replacement of parts easier and quicker.

This results in less downtime for systems, fewer emergency repairs, and lower lifecycle costs.

Regulatory & Compliance Advantages

Meeting regulations is not optional — in many regions it’s legally required, especially for public infrastructure, industrial facilities, or fire safety systems.

Certifications and Standards

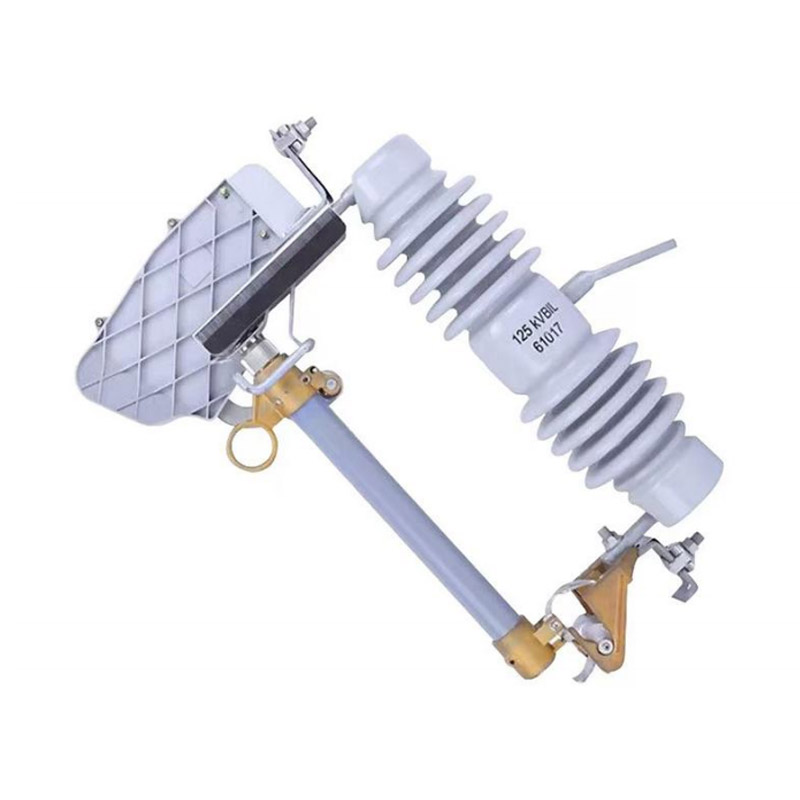

Many junction boxes intended for demanding or hazardous areas must meet specific standards such as ATEX/IECEx for explosion proofing, or standard ratings for fire resistance, ingress protection (IP), and impact resistance (IK). For example:

There are junction box designs that provide fire protection in tunnel or building safety systems, maintaining functionality for up to 90 minutes under fire.

Enclosures with IP66 rating resist strong water jets and dust ingress, which is required in many outdoor or harsh-environment applications.

Use of ATEX-certified junction boxes ensures safe operation in hazardous gas or dust zones.

Using a properly certified circuit breaker block junction box means the overcurrent protection, wiring terminations, and enclosures are matched for specifications that authorities expect, helping avoid fines, failed inspections, or unsafe installations.

Legal Requirements & Risk Mitigation

Building codes or electrical codes often require that all wire splices be enclosed in junction boxes. Failing this can cause to violations.

Enclosures must often have covers, be sealed, and have appropriate strain relief for cables. Missing these features can mean insurance or safety liability issues.

In hazardous environments, using an uncertified or underspecified junction box could pose explosion or fire risk. Certifications (ATEX/IECEx) serve to demonstrate compliance and reduce liability.

Recommendations for Specifiers & Installers

To maximize efficiency, compliance, and cost savings, consider the following:

Specify certifications early — don’t leave ATEX, IP, IK, or fire rate requirements until late in design.

Choose modular or breaker block-capable enclosures to reduce complexity.

Account for environmental demands — outdoor locations, moisture, chemical exposure, vibration all affect enclosure choice.

Plan for future expansion — extra capacity, spare positions for breakers, slack wiring space saves time later.

Ensure proper cable entry, strain relief, and grounding are part of enclosure design.

English

English Español

Español عربى

عربى