Effective electrical connections depend on more than simply matching cable sizes. Whether you’re securing a power conductor with a...

READ MOREChina TB TC TD Terminal Supplier

Sleeve Crimping Pliers

| Model | L (mm) |

Crimping capacity ( m㎡) |

Crimping effect | AWG | |||||||||||||||||||||||||||||||||||

| HSC8/6-4A | 175 | 0.25~6.0 | Regular quadrilateral |

24-8AWG | |||||||||||||||||||||||||||||||||||

| HSC8/6-6A | 173 | 0.25~6.0 | Regular hexagon | 24-10AWG | |||||||||||||||||||||||||||||||||||

| Model | L (mm) |

W (mm) |

Clamp head material |

Crimp port | |||||||||||||||||||||||||||||||||||||

| NW168 | 188 | 48.3 | Q235(A3) Carbon structural steel |

8P/6P | |||||||||||||||||||||||||||||||||||||

Insulated Terminal Crimping Pliers

| Model | L (mm) |

W (mm) |

Crimping range (m㎡) |

Applicable Ports | |||||||||||||||||||||||||||||||||||||||

| HS-40J | 233 | 70 | 0.25~6 | Pre-Insulated Ports | |||||||||||||||||||||||||||||||||||||||

OT Special Crimping Pliers

| Model | L (mm) |

Jaw thickness (mm) |

Crimping range | Applicable ports |

| IWS-5100A | 381 | 9.1 | 2.5-25mm² | 5A-100A |

| IWS-8200A | 185 | 10-28 | 16-35mm² | 60A-200A |

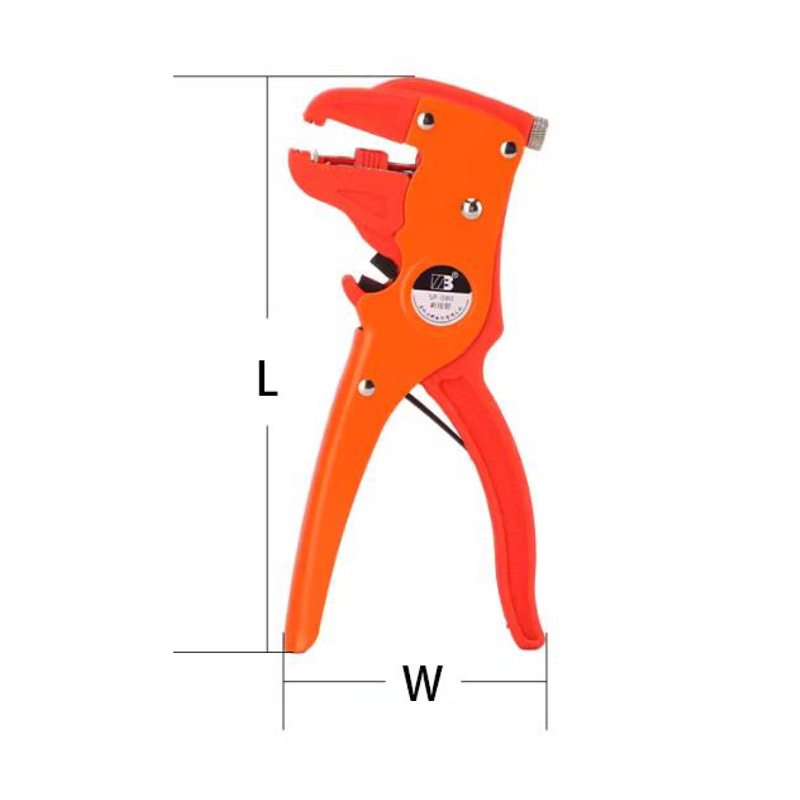

Multi-Purpose Duck Bill Stripping Pliers

| Model | L (mm) |

W (mm) |

Stripping range (m㎡) |

Cutting range | |||||||||||||||||||||||||||||||||||

| Single stranded wire |

173 | 83 | 0.5-3.3 (Core cross-section) |

0.08-2.0m㎡ | |||||||||||||||||||||||||||||||||||

| 0.8-2.0 (Core Diameter) |

|||||||||||||||||||||||||||||||||||||||

| multi stranded wire |

0.5-5.5 (Core cross-section) |

0.09-3.5m㎡ | |||||||||||||||||||||||||||||||||||||

| 0.8-2.6 (Core Diameter) |

|||||||||||||||||||||||||||||||||||||||

| row of wires | 0.5-3.5 | 8mm(max) | |||||||||||||||||||||||||||||||||||||

Multi-Function Pliers

| Model | L (mm) |

Crimping range | Stripping range | ||||||||||||||||||||||||||||||||||||

| 7-in-1 Wire Stripping Pliers |

175 | 12-20 | 0.8/1.0/1.6/2.0/2.6m㎡ | ||||||||||||||||||||||||||||||||||||

| Crimping and stripping pliers |

185 | 10-28 | 1.0/1.3/1.6/2.0m㎡ | ||||||||||||||||||||||||||||||||||||

Universal Measuring Pen

| Model | AC VOLTAGE | Weight | Material | ||||||||||||||||||||||||||||||||||||

| Universal measuring pen |

0V-600V | 38g | ABS+metal | ||||||||||||||||||||||||||||||||||||

Non-Contact Electric Pen

| Model | A.C. voltage |

Frequencys | Security level | Battery model |

Sizes | ||||||||||||||||||||||||||||||||||||||

| AC1010+ | 12V~ 1000V AC |

50Hz/60Hz | CAT.III 1000V/CAT.IV 600V;CE |

2*1.5V AAA |

157mm/26.4m m/23/mm |

||||||||||||||||||||||||||||||||||||||

Insulating Tape

| Model | L (m) | W (mm) | Material | ||||||||||||||||||||||||||||||||||||

| Insulating tape 1 | 10 | 25 | PVC | ||||||||||||||||||||||||||||||||||||

| Insulating tape 2 | 10 | 50 | PVC | ||||||||||||||||||||||||||||||||||||

Electroprobe

| Model | L (mm) |

Applicable objects | Types of electronic | |||||||||||||||||||||||||||||||||||||||

| Electroprobe | 180 | low voltage | contact | |||||||||||||||||||||||||||||||||||||||

Wire Connertor

Product Name: Wire Connector

Shell Material: PA

Guide Material: High Quality

Impulse Voltage: 4KV

Product Use: Used for connecting parts of electric wires such as motor, electrical control, supply. household appliances, lighting, machinery, etc.

Multi Functional Professional Set

Product Name: Multi Functional Professional Set

Weight: 4.1kg

Size: 400*310*90mm

Texture of Material: PE Engineering Plastics

Usage Scenarios: Home Repair/ Equipment Repair

Nylon cable glahds

Producf material: LocationA,C,E and F made of PA, Location D made of chemigum.

Specification of thread: Metric, PG and G

Working temperature: Static:-40°C~+100°C, instantaneously san be +120C; Dynamic:-20C~+80C,instantaneously can br +100°℃;

Color: Black and gray(special colors customizable)

Protection classification: Within the specified clamp range,use O-shaped sealing ring and screw tight the pressing fastener reaching Ip65.

Property: thespecial designs forclamping jawand sealants fitedwith pressing fasrener cansaveboth time and energypromising awide scope forcable

clamping and extremely great strerching resistance.lt is water resistant,dustrwsisant and inactivewithsalts,acids,alkalis,oils and greases as well as general dissolvent,

How to use: waterproof nylon cable glands aue the fittings for cables.The joints can lock the cables tight.The other end of thejont can be either connected

with the housing of equipments or conneceted with electric equipment with inner threaded access hole as per the thread selected.

PG Thread

| ltem NO. | PG | Cable range (mm) |

D1 | D2 | L1 | L2 | L3 | B1 |

| PG-07 | PG7 | 3.5-6 | 10.9 | 8.1 | 10.4 | 14.5 | 10.5 | 6.4 |

| PG-09 | PG9 | 4-8 | 15.3 | 12.2 | 9.9 | 15.8 | 17.2 | 8.6 |

| PG-11 | PG11 | 5-10 | 17.9 | 14.6 | 10.6 | 15.5 | 17.5 | 10.7 |

| PG-13.5 | PG13.5 | 6-12 | 20.2 | 16.2 | 10.3 | 17.8 | 17.9 | 13.3 |

| PG-16 | PG16 | 10-14 | 21.3 | 18.3 | 11.2 | 18.5 | 20.5 | 14.3 |

| PG-19 | PG19 | 12-15 | 24.7 | 20.5 | 11.4 | 18.6 | 21.8 | 15.5 |

| PG-21 | PG21 | 13-18 | 26.9 | 21.8 | 11.6 | 18.7 | 23.1 | 16.7 |

| PG-24 | PG24 | 15-22 | 29.8 | 25.0 | 12.1 | 19.3 | 24.1 | 19.2 |

| PG-27 | PG27 | 17-23 | 29.8 | 25.0 | 12.1 | 19.3 | 24.1 | 19.2 |

| PG-29 | PG29 | 18-25 | 35.1 | 29.8 | 12.4 | 22.6 | 24.8 | 24.8 |

| PG-36 | PG36 | 22-32 | 44.7 | 37.1 | 12.6 | 25.1 | 26.1 | 30.7 |

| PG-42 | PG42 | 30-38 | 50.4 | 43.3 | 17.3 | 25.9 | 30.5 | 35.6 |

| PG-48 | PG48 | 34-44 | 56.1 | 48.2 | 20.9 | 28.1 | 31.5 | 41.4 |

| PG-63 | PG63 | 42-54 | 71.0 | 63.5 | 27.5 | 31.5 | 43.5 | 55.0 |

Metric Thread

| ltem NO. | METRIC | Cable range (mm) |

D1 | D2 | L1 | L2 | L3 | B1 |

| M12 | M12×1.5 | 3.5-6 | 12 | 9 | 10.4 | 14.5 | 14 | 6.4 |

| M16 | M16×1.5 | 4-8 | 15.3 | 12.2 | 9.9 | 13 | 16 | 8.6 |

| M18 | M18×1.5 | 5-10 | 17.9 | 14.6 | 10.6 | 15.5 | 17.5 | 10.7 |

| M20 | M20×1.5 | 6-12 | 20.2 | 16.2 | 10.3 | 17.8 | 17.9 | 13.3 |

| M22 | M22×1.5 | 10-14 | 21.3 | 18.3 | 11.2 | 18.5 | 20.5 | 14.3 |

| M24 | M24×1.5 | 12-15 | 24.7 | 20.5 | 11.4 | 18.6 | 21.8 | 15.5 |

| M27 | M27×1.5 | 13-18 | 26.9 | 21.8 | 11.6 | 18.7 | 23.1 | 16.7 |

| M30 | M30×1.5 | 15-22 | 29.8 | 25.0 | 12.1 | 19.3 | 24.1 | 19.2 |

| M32 | M32×1.5 | 17-23 | 29.8 | 25.0 | 12.1 | 19.3 | 24.1 | 19.2 |

| M36 | M36×1.5 | 18-25 | 35.1 | 29.8 | 12.4 | 22.6 | 24.8 | 24.8 |

| M46 | M46×1.5 | 22-32 | 44.7 | 37.1 | 12.6 | 25.1 | 26.1 | 30.7 |

| M54 | M54×1.5 | 30-38 | 50.4 | 43.3 | 17.3 | 25.9 | 30.5 | 35.6 |

| M60 | M60×1.5 | 34-44 | 56.1 | 48.2 | 20.9 | 28.1 | 31.5 | 41.4 |

| M70 | M70×1.5 | 42-54 | 71.0 | 63.5 | 27.5 | 31.5 | 43.5 | 55.0 |

G thread

| ltem NO. | G thread | Cable range (mm) |

D1 | D2 | L1 | L2 | L3 | B1 |

| G1/2" | G1/2" | 6-12 | 20.2 | 16.2 | 10.3 | 17.8 | 17.9 | 13.3 |

| G3/4" | G3/4" | 13-18 | 26.9 | 21.8 | 11.6 | 18.7 | 23.1 | 16.7 |

| G1" | G1" | 15-22 | 29.8 | 25.0 | 12.1 | 19.3 | 24.1 | 19.2 |

| G1/1/4" | G1/1/4" | 18-25 | 35.1 | 29.8 | 12.4 | 22.6 | 24.8 | 24.8 |

| G1/1/2" | G1/1/2" | 22-32 | 44.7 | 37.1 | 12.6 | 25.1 | 26.1 | 30.7 |

| G2" | G2" | 34-44 | 56.1 | 48.2 | 20.9 | 28.1 | 31.5 | 41.4 |

Search

Categories

-

Energy Measuring Terminal Block(314)

- Energy Measuring Joint Terminal Block(16)

- Polycarbonate Energy Measuring Terminal Block(24)

- Standard Wiring Energy Measuring Terminal Block(4)

- Transparent Shell Energy Measuring Terminal Block(6)

- Multifunctional Test Energy Measuring Terminal Block(10)

- Intelligent Safety Energy Measuring Terminal Block(6)

- Single-Phase Multi-Circuit Output Terminal Block(12)

- Self-Elevating Metering Box Terminal Block(7)

- One Household One-Meter Meter Box Dedicated Terminal Block(56)

- Three-Phase Metering Box Dedicated Terminal Block(24)

- Repeatable Grounding Line Terminal Block(20)

- Terminal Block for One-Inlet Multi-Outlet Metering Box(15)

- Closed Terminal Block(11)

- Heavy Current Terminal Block(48)

- Self-Boosting Terminal Block(5)

- Intelligent Self-Locking Terminal Block(3)

- Tool-Free Crimping Type Terminal Block(5)

- Wide Range of Wire Diameters Terminal Block(5)

- Combined Type Energy Measuring Terminal Block(37)

-

Switch Terminal Block(55)

- Pin-Type Incoming Line Switch Terminal Block(4)

- Multi-Way Connection Switch Terminal Block(4)

- Plug-pin Switch Terminal Block(7)

- Combined Type Switch Terminal Block(7)

- High Contact Cross Section Switch Terminal Block(7)

- Wide Range Switch Terminal Block(11)

- One Way in Switch Terminal Block(12)

- Equipped with Circuit Breaker Switch Terminal(3)

-

Heavy-current Terminal Block(631)

- Modular Building Block Terminal Block(156)

- Spherical Non-Destructive Crimp Terminal(120)

- Dual-Mode Connection Electrical Terminal(90)

- Anti-Electricity-Theft Terminal Block(74)

- Convenient Connection Terminal Block(12)

- High-Contact Section Terminal Block(12)

- Wide Range of Wire Diameters Neutral Line Terminal(9)

- Heavy-Current Neutral Line Terminal(9)

- Upper and Lower Rows of Neutral Terminal(2)

- Independent Neutral Line Terminal(7)

- Nose-Type Neutral Line Terminal(7)

- Rail Type Neutral Line Terminal(9)

- Fixed Neutral Line Terminal(12)

- Double Rail Assembly Electrical Terminal(19)

- Blue Jack-Up Terminal(6)

- Black Base Copper Bar Terminal(5)

- Compact Terminal Block(16)

- Precision Terminal Block(23)

- U-Shaped Harpoon Terminal(2)

- Grounding Metering Box Terminal Block(12)

- High-Performance Terminal Block(19)

- Multifunctional Terminal Block(10)

- Din Rail Terminal Block(76)

- Watt-hour Meter Connector(49)

-

Energy Meter Accessories(116)

-

-

In electrical systems, reliable terminations are just as crucial as the conductors themselves. Whether you are dealing with power ...

READ MORE -

When working with electrical systems, properly seating stranded wire in a cable lug or wire connector is essential for a secure an...

READ MORE -

Ensuring safety and reliability in electrical panels begins with selecting the Correct components. Terminal Blocks play a crucial ...

READ MORE -

Modern electrical control panels often face the challenge of accommodating a growing number of circuits within limited space. Term...

READ MORE -

Overheating and loose contacts in terminal blocks can compromise system safety and reliability. Proper installation, maintenance, ...

READ MORE

How to Use Connector Terminals?

1. Core Principles: Safety!

Before you touch any wires, always follow these rules:

Power Off: Always disconnect power at the source before making or modifying any connections. Verify with a multimeter or voltage tester that the circuit is dead.

Right Tool for the Job: Using the proper tools (wire strippers, crimpers, screwdrivers) is not just a recommendation—it's essential for a safe connection.

Match the Specifications: Ensure the terminal is rated for the voltage and current (amps) of your circuit. Using an under-rated terminal is a fire hazard.

Secure Connections: Loose connections cause arcing, heat buildup, and failure. Tug on the wire after connecting to ensure it's secure.

2. Common Types of Connector Terminals & How to Use Them

Here's a breakdown of the frequently encountered terminals.

A. Screw Terminals

These are very common in household outlets, light switches, industrial control panels, and many consumer electronics.

How They Work: A screw clamps down on a wire (either bare or with a ferrule) to make a connection.

How to Use:

Strip the Wire: Strip about 3/4" (10-12mm) of insulation from the wire.

Prepare the Wire (Recommended): For stranded wire, always use a ferrule or twist the strands neatly clockwise and tin them with a small amount of solder to prevent fraying. (Note: Some experts advise against soldering for screw terminals under vibration, as it can make the wire brittle. A ferrule is often the solution.)

- Loosen the Screw: Turn the screw counterclockwise until there is enough space to insert the wire.

- Insert the Wire: Place the bare wire under the screw terminal plate or into the insertion hole.

- Tighten the Screw: Tighten the screw firmly clockwise. Do not overtighten, as this can strip the screw threads or cut the wire.

- Tug Test: Gently pull on the wire to ensure it is held fast.

B. Crimp Terminals (Spade, Ring, Butt Splices)

These are ubiquitous in automotive, appliance, and low-voltage DC wiring. They require a special tool called a crimper.

Types:

Spade (Fork) Terminal: Easy to connect and disconnect. Good for spaces where a ring terminal won't fit.

Ring Terminal: Provides the secure, permanent connection. The screw is completely captured, preventing it from slipping out.

Butt Splice: Used to connect two wires end-to-end.

Pin Terminal: Used in plastic housing connectors (e.g., Molex, JST).

How to Use (The Crimping Process):

Strip the Wire: Strip a length of insulation that matches the metal barrel of the terminal.

Select the Correct Size: Terminals and crimpers are sized by wire gauge (e.g., 22-16 AWG) and stud size (e.g., #8, 1/4"). Match them correctly.

Insert and Crimp:

Place the metal barrel of the terminal into the correctly sized slot on your crimping tool.

Insert the bare wire into the barrel until it is flush with the end.

Squeeze the crimper handles with firm, even pressure until it releases or fully closes.

The crimp should be tight and uniform, not smashed or crooked.

What Are the Differences Between TB, TC, and TD Terminals?

When choosing between different types of terminals, how do TB, TC, and TD varieties compare? Could a simple table clarify their main distinctions?

| Terminal Type | Main Function | Typical Use Case | Key Feature |

| TB (Terminal Block) | Provides a base for multiple wire connections | Control panels, distribution boards | Modular structure for neat arrangement |

| TC (Terminal Connector) | Connects two or more conductors directly | Wiring in appliances or small circuits | Simple and compact design |

| TD (Terminal Distribution) | Distributes one input to several outputs | Power distribution systems | Efficient splitting of circuits |

Is the FJ6 Terminal Suitable for 240V?

When considering voltage ratings, how can one determine whether a specific terminal, such as the FJ6, is suitable for 240V systems? Does it depend on the manufacturer's specification, the material, and the design?

Is it important to verify the rated voltage and current capacity of the FJ6 terminal before installation? If the FJ6 is generally rated for household and light industrial applications, could it be expected to handle 240V under normal conditions? Yet, should one also ask whether environmental factors, such as humidity, dust, or heat, might affect its performance?

Would it be reasonable to compare the FJ6 terminal to other commonly used terminals to see how it performs under similar voltage levels? If the insulation material is of sufficient quality and the clamping mechanism is firm, might it support safe operation at 240V? Conversely, if the wire gauge is incompatible or the terminal is improperly tightened, could that overheating or reduced reliability?

Should electricians or technicians consult the product datasheet before using the FJ6 terminal in 240V circuits? Could compliance with local electrical standards serve as a guide in confirming suitability? Ultimately, is it fair to say that the FJ6 terminal can be considered suitable for 240V if used within its rated specifications and installed according to proper practices?

English

English Español

Español عربى

عربى