Integrating wired connectivity into the era of automation and digital networking involves more than just traditional hardware. A H...

READ MOREPrecision Terminal Block Manufacturer

Precision Terminal Blocks are professionally used for creating highly accurate and reliable electrical connections in applications that demand exacting standards of performance. These terminal blocks are specifically designed to provide precise and stable connections, making them ideal for use in sensitive electrical systems, control panels, and instrumentation equipment where reliability and accuracy are critical.

These terminal blocks feature a high-precision design that ensures secure and stable connections of conductors, minimizing electrical resistance and signal integrity. They are engineered with advanced materials and manufacturing processes to withstand demanding operating conditions, with an insulation voltage of up to 690V and a rated voltage of 380V. The compact and modular design allows for easy installation and integration into various electrical systems, while also providing scalability to accommodate future expansion.

Precision Terminal Blocks are currently a solution for managing electrical connections in high-precision applications. They simplify the wiring process by providing a reliable and accurate connection point, enhance system reliability through their robust construction, and ensure the integrity of electrical signals. Their versatile design makes them suitable for a wide range of applications, including industrial automation, telecommunications, and precision instrumentation, where high-quality connections are essential.

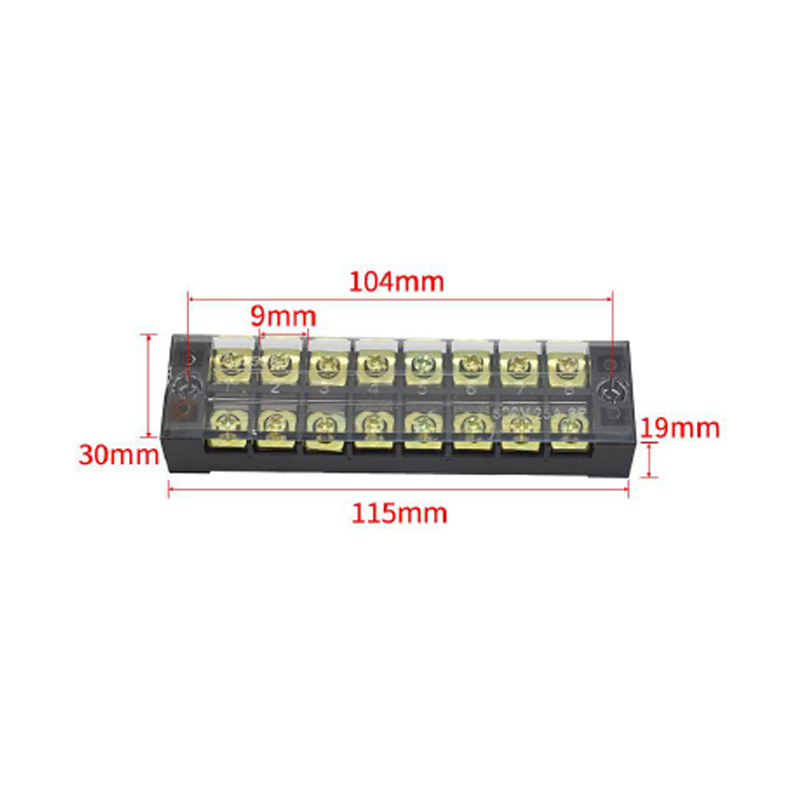

TB-2506L Terminal

Model:TB2506L

Type:25A

Category: 3P/4P/5P/6P/8P/10P/12P

Screw:Blue and white plating/nickel plating/multicolored plating

Rated voltage: 600V

Wiring area: 0.5mm²-4mm²

Material:Brass/Iron

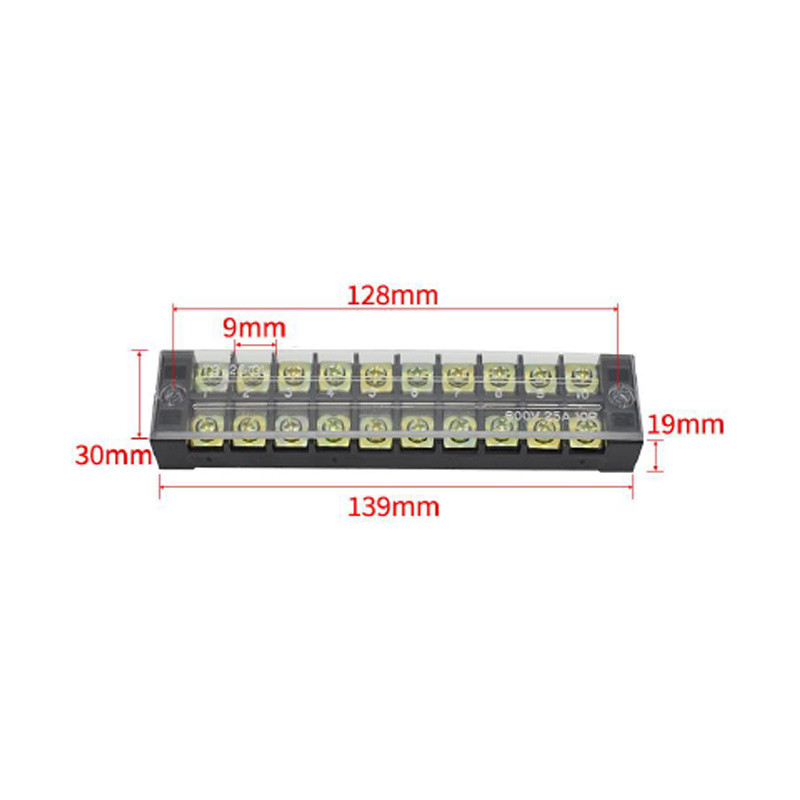

TB-2508L Terminal

Model:TB2508L

Type:25A

Category: 3P/4P/5P/6P/8P/10P/12P

Screw:Blue and white plating/nickel plating/multicolored plating

Rated voltage: 600V

Wiring area: 0.5mm²-4mm²

Material:Brass/Iron

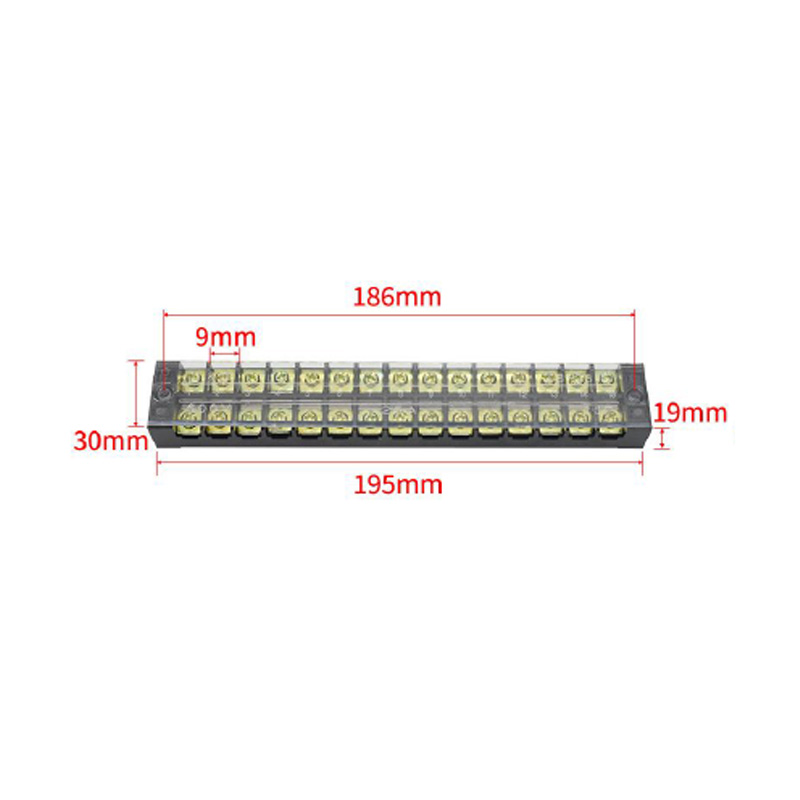

TB-2510L Terminal

Model:TB2510L

Type:25A

Category: 3P/4P/5P/6P/8P/10P/12P

Screw:Blue and white plating/nickel plating/multicolored plating

Rated voltage: 600V

Wiring area: 0.5mm²-4mm²

Material: Brass/Iron

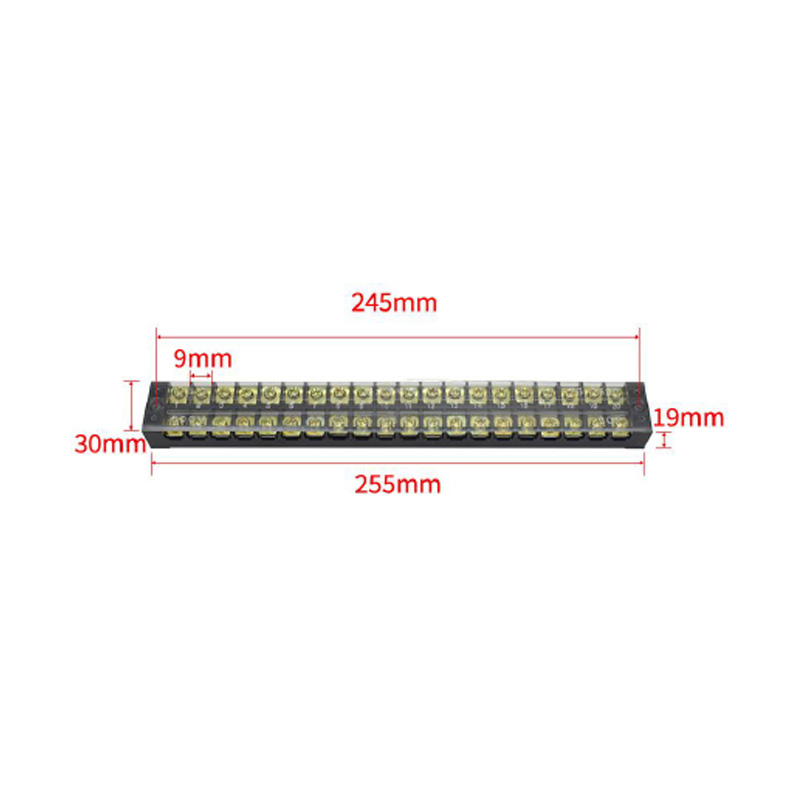

TB-2512L Terminal

Model: TB2512L

Type: 25A

Category: 3P/4P/5P/6P/8P/10P/12P

Screw: Blue and white plating/nickel plating/multicolored plating

Rated voltage: 600V

Wiring area: 0.5mm²-4mm²

Material: Brass/Iron

TB-2515L Terminal

Model:TB2515L

Type:25A

Category:3P/4P/5P/6P/8P/10P/12P

Screw:Blue and white plating/nickel plating/multicolored plating

Rated voltage: 600V

Wiring area: 0.5mm²-4mm²

Material:Brass/Iron

TB-2520L Terminal

Model:TB2520L

Type:25A

Category:3P/4P/5P/6P/8P/10P/12P

Screw:Blue and white plating/nickel plating/multicolored plating

Rated voltage: 600V

Wiring area: 0.5mm²-4mm²

Material: Brass/Iron

TB-4503L Terminal

Model:TB4503L

Type:45A

Category:3P/4P/5P/6P/8P/10P/12P

Screw:Blue and white plating/nickel plating/multicolored plating

Rated voltage: 600V

Wiring area: 0.5mm²-4mm²

Material:Brass/Iron

TB-4504L Terminal

Model: TB4504L

Type: 45A

Category: 3P/4P/5P/6P/8P/10P/12P

Screw: Blue and white plating/nickel plating/multicolored plating

Rated voltage: 600v

Wiring area: 0.5mm²-4mm²

Material: Brass/Iron

TB-4506L Terminal

Model: TB4506L

Type: 45A

Category: 3P/4P/5P/6P/8P/10P/12P

Screw: Blue and white plating/nickel plating/multicolored plating

Rated voltage: 600V

Wiring area: 0.5mm²-4mm²

Material: Brass/Iron

TB-4510L Terminal

Model: TB4510L

Type: 45A

Category:3P/4P/5P/6P/8P/10P/12P

Screw: Blue and white plating/nickel plating/multicolored plating

Rated voltage: 600v

Wiring area: 0.5mm²-4mm²

Material: Brass/Iron

TB-4512L Terminal

Model: TB4512L

Type: 45A

Category: 3P/4P/5P/6P/8P/10P/12P

Screw: Blue and white plating/nickel plating/multicolored plating

Rated voltage: 600V

Wiring area: 0.5mm²-4mm²

Material: Brass/Iron

Search

Categories

-

Energy Measuring Terminal Block(314)

- Energy Measuring Joint Terminal Block(16)

- Polycarbonate Energy Measuring Terminal Block(24)

- Standard Wiring Energy Measuring Terminal Block(4)

- Transparent Shell Energy Measuring Terminal Block(6)

- Multifunctional Test Energy Measuring Terminal Block(10)

- Intelligent Safety Energy Measuring Terminal Block(6)

- Single-Phase Multi-Circuit Output Terminal Block(12)

- Self-Elevating Metering Box Terminal Block(7)

- One Household One-Meter Meter Box Dedicated Terminal Block(56)

- Three-Phase Metering Box Dedicated Terminal Block(24)

- Repeatable Grounding Line Terminal Block(20)

- Terminal Block for One-Inlet Multi-Outlet Metering Box(15)

- Closed Terminal Block(11)

- Heavy Current Terminal Block(48)

- Self-Boosting Terminal Block(5)

- Intelligent Self-Locking Terminal Block(3)

- Tool-Free Crimping Type Terminal Block(5)

- Wide Range of Wire Diameters Terminal Block(5)

- Combined Type Energy Measuring Terminal Block(37)

-

Switch Terminal Block(55)

- Pin-Type Incoming Line Switch Terminal Block(4)

- Multi-Way Connection Switch Terminal Block(4)

- Plug-pin Switch Terminal Block(7)

- Combined Type Switch Terminal Block(7)

- High Contact Cross Section Switch Terminal Block(7)

- Wide Range Switch Terminal Block(11)

- One Way in Switch Terminal Block(12)

- Equipped with Circuit Breaker Switch Terminal(3)

-

Heavy-current Terminal Block(631)

- Modular Building Block Terminal Block(156)

- Spherical Non-Destructive Crimp Terminal(120)

- Dual-Mode Connection Electrical Terminal(90)

- Anti-Electricity-Theft Terminal Block(74)

- Convenient Connection Terminal Block(12)

- High-Contact Section Terminal Block(12)

- Wide Range of Wire Diameters Neutral Line Terminal(9)

- Heavy-Current Neutral Line Terminal(9)

- Upper and Lower Rows of Neutral Terminal(2)

- Independent Neutral Line Terminal(7)

- Nose-Type Neutral Line Terminal(7)

- Rail Type Neutral Line Terminal(9)

- Fixed Neutral Line Terminal(12)

- Double Rail Assembly Electrical Terminal(19)

- Blue Jack-Up Terminal(6)

- Black Base Copper Bar Terminal(5)

- Compact Terminal Block(16)

- Precision Terminal Block(23)

- U-Shaped Harpoon Terminal(2)

- Grounding Metering Box Terminal Block(12)

- High-Performance Terminal Block(19)

- Multifunctional Terminal Block(10)

- Din Rail Terminal Block(76)

- Watt-hour Meter Connector(49)

-

Energy Meter Accessories(116)

-

-

Secure connections are essential for reliable electrical distribution, especially when installing a High-performance Terminal Bloc...

READ MORE -

For engineers and panel builders striving for both efficiency and reliability, wiring errors remain a persistent headache — even w...

READ MORE -

In modern electrical systems, a High-performance Terminal Block plays a critical role in ensuring secure and reliable connections ...

READ MORE -

When building or maintaining electrical systems, one frequently overlooked but critical factor is matching the conductor size to t...

READ MORE -

Effective electrical connections depend on more than simply matching cable sizes. Whether you’re securing a power conductor with a...

READ MORE

What Is The Precision Of The Precision Double Rows Covered Terminal Strip?

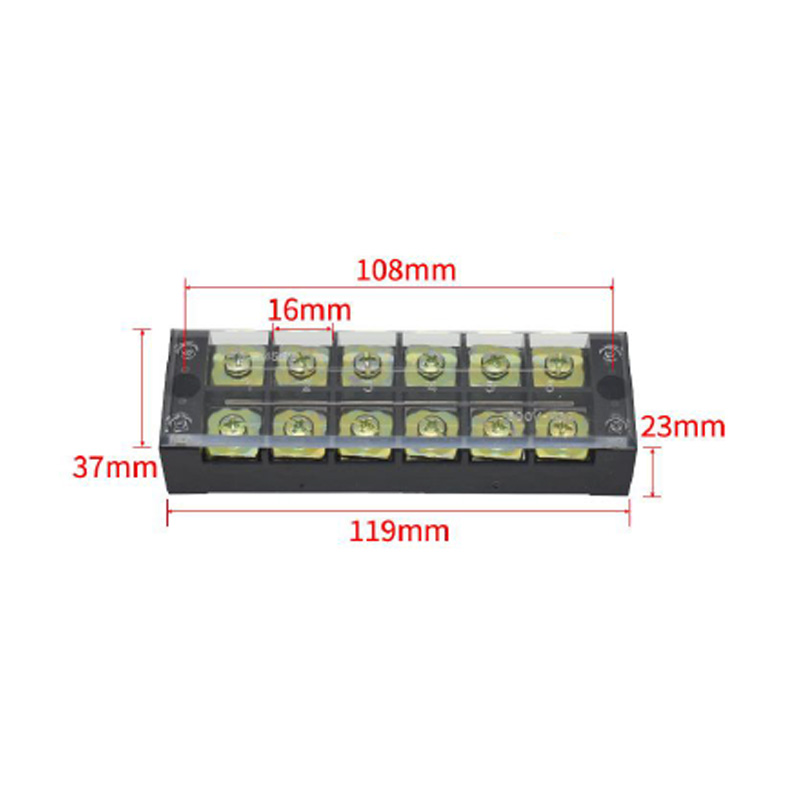

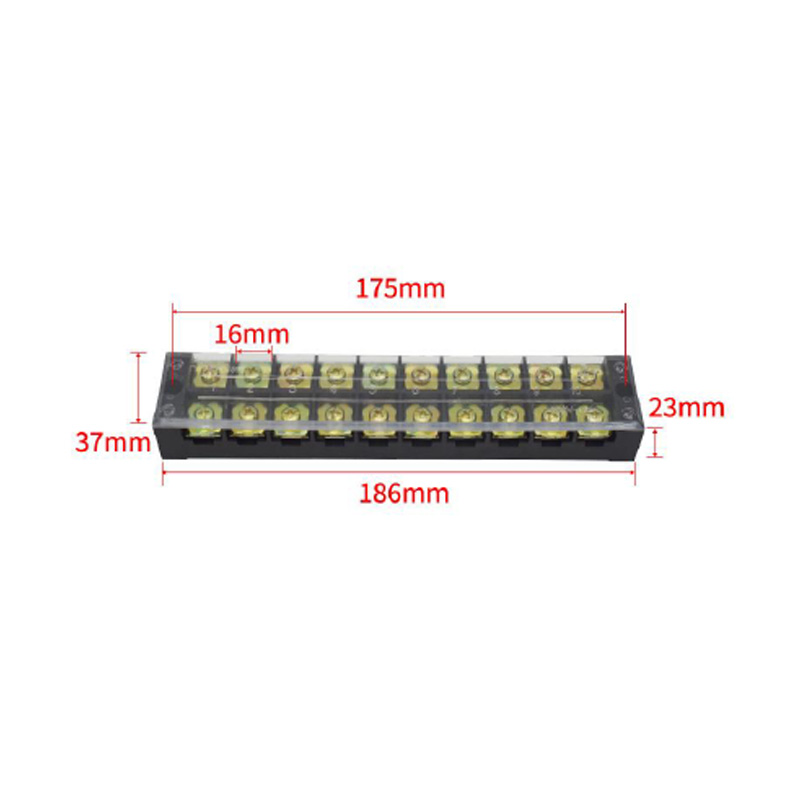

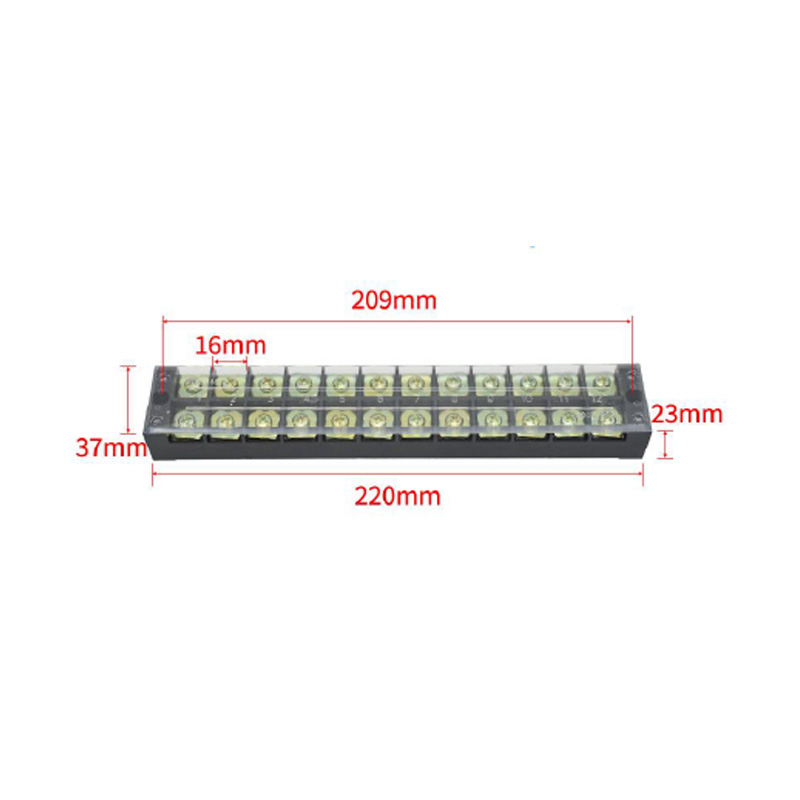

Double rows covered terminal strips block are a type of electrical connector designed to provide a secure and reliable connection for wires in a wide range of applications. These terminal strips feature a dual-row design, allowing for a higher density of connections in a compact space. The precision of these terminal strips is crucial in ensuring the reliability and safety of electrical connections.

Key Features of Precision Double Rows Covered Terminal Strips

· Dual Row Design: These terminal strips feature two rows of connection points, allowing for a higher density of connections in a compact space.

· Covered Design: The Double rows covered terminal strips have a removable clear plastic insulating cover, which helps prevent circuit disorders and accidental contact with live wires.

· Screw Barrier Terminal Block: The terminal block features screw-type connections, which provide a secure and reliable connection for wires.

· High-Voltage Rating: These terminal strips have a high voltage rating, typically up to 600V or 660V, making them suitable for use in a wide range of applications.

· Current Rating: The current rating of these terminal strips varies, but typically ranges from 25A to 30A.

Precision Machining and Materials

The precision of double rows covered terminal strips is achieved through the use of advanced materials and manufacturing techniques. These terminal strips are made with high-quality materials, such as copper or brass, which provide electrical conductivity and durability. The precision machining process ensures that the terminal strips have a precise and consistent design, which is essential for reliable electrical connections ¹.

Applications of Double Rows Covered Terminal Strips

Double rows covered terminal strips are used in a wide range of applications, including ² ³:

· Industrial Control Systems: These terminal strips are used in industrial control systems to connect and manage wires.

· Power Supplies: They are used in power supplies to connect and distribute power to various components.

· Communication Systems: Double rows covered terminal strips are used in communication systems to connect and manage wires.

· Automotive and Marine Applications: They are also used in automotive and marine applications to connect and manage wires.

Benefits of Using Double Rows Covered Terminal Strips

The use of double rows covered terminal strips provides several benefits, including:

· Increased Connection Density: The dual-row design allows for a higher density of connections in a compact space.

· Improved Safety: The covered design and screw barrier terminal block help prevent accidental contact with live wires.

· Reliable Connections: The screw-type connections provide a secure and reliable connection for wires.

· Easy Installation: These terminal strips are easy to install and maintain, reducing the time and effort required for wiring and troubleshooting.

The precision of double rows covered terminal strips is achieved through the use of advanced materials and manufacturing techniques. These terminal strips provide a reliable and secure connection for wires in a wide range of applications. Their dual-row design, covered design, and screw barrier terminal block make them an ideal choice for applications where space is limited and reliability is crucial. By understanding the precision and benefits of double rows covered terminal strips, manufacturers and engineers can design more efficient and reliable electrical systems.

English

English Español

Español عربى

عربى