Integrating wired connectivity into the era of automation and digital networking involves more than just traditional hardware. A H...

READ MOREMultifunctional Terminal Block Manufacturer

Multifunctional Terminal Blocks are professionally used for creating versatile and efficient electrical connections in a wide range of applications. These terminal blocks are specifically designed to handle multiple functions in a single unit, making them ideal for applications that require a compact, reliable, and multifaceted solution for electrical wiring and control.

These terminal blocks feature an advanced design that allows for secure and stable connections of various types of conductors, without the need for excessive wiring or additional components. They integrate multiple functionalities, such as voltage measurement, signal distribution, and power management, into a single terminal block, reducing the need for multiple components and simplifying the overall wiring process.

Multifunctional Terminal Blocks are currently a versatile and reliable solution for managing complex electrical connections. They simplify the wiring process, enhance system reliability, and provide a safe and efficient way to manage multiple circuits and functions in a single terminal block. Their modular design ensures easy installation and scalability, making them suitable for a wide range of residential, commercial, and industrial applications.

The Multifunctional Terminal Block is built to last. Constructed from high-quality materials, they are designed to withstand the wear and tear of continuous use in harsh environments. This durability ensures that they maintain their integrity over time, reducing the need for frequent replacements and less downtime.

These terminal blocks are made from materials with outstanding electrical conductivity, ensuring efficient power transfer and less energy loss. This feature is crucial in applications where energy efficiency is important, such as in renewable energy systems or large-scale industrial plants.

Wiring Terminal

Product Name: Wiring Terminal

Produt Material: PA

Conductor Material: Zinc Copper Plating

Rated Voltage: 400V

Rated Current: 32A

Wiring Rang: 0.08~4mm2

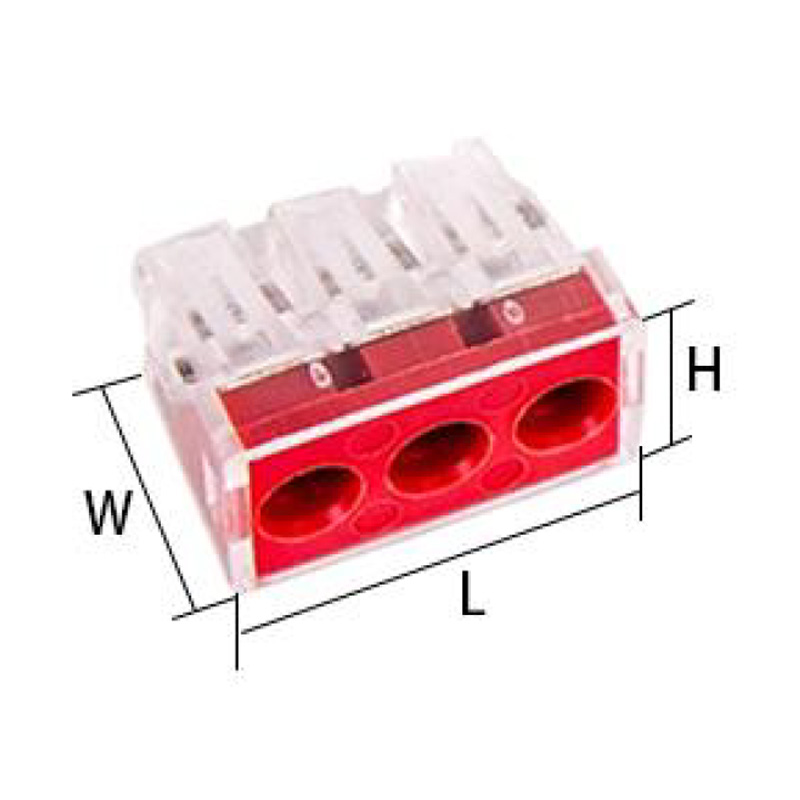

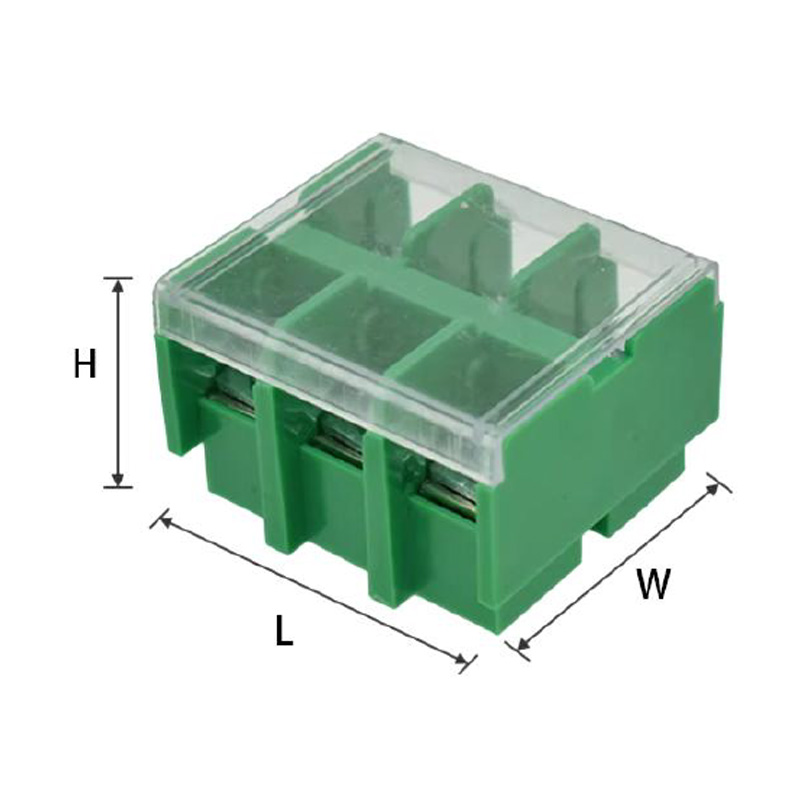

Quick Terminal Block

| Model | L (m m) |

W (mm) |

H (m m) |

Rated Voltage (V) |

Rated Current (A) |

Single Strand Wire (m ㎡) |

Multi- Stranded Wire (m ㎡) |

|||||||||||||||||||||||||||||||

| PCT-102 | 13 | 19 | 9 | 250 | 24 | 0.75~2.5 | 1.5~2.5 | |||||||||||||||||||||||||||||||

| PCT-103 | 26 | 20 | 16 | 400 | 40 | 1.5~6 | 2.5~6 | |||||||||||||||||||||||||||||||

| PCT-104 | 13 | 19 | 13 | 250 | 24 | 0.75~2.5 | 1.5~2.5 | |||||||||||||||||||||||||||||||

| PCT- 104D |

33 | 20 | 14 | 400 | 40 | 1.5~6 | 2.5~6 | |||||||||||||||||||||||||||||||

| PCT-106 | 19 | 18 | 13 | 250 | 24 | 0.75~2.5 | 1.5~2.5 | |||||||||||||||||||||||||||||||

| PCT-108 | 19 | 24 | 13 | 250 | 24 | 0.75~2.5 | 1.5~2.5 | |||||||||||||||||||||||||||||||

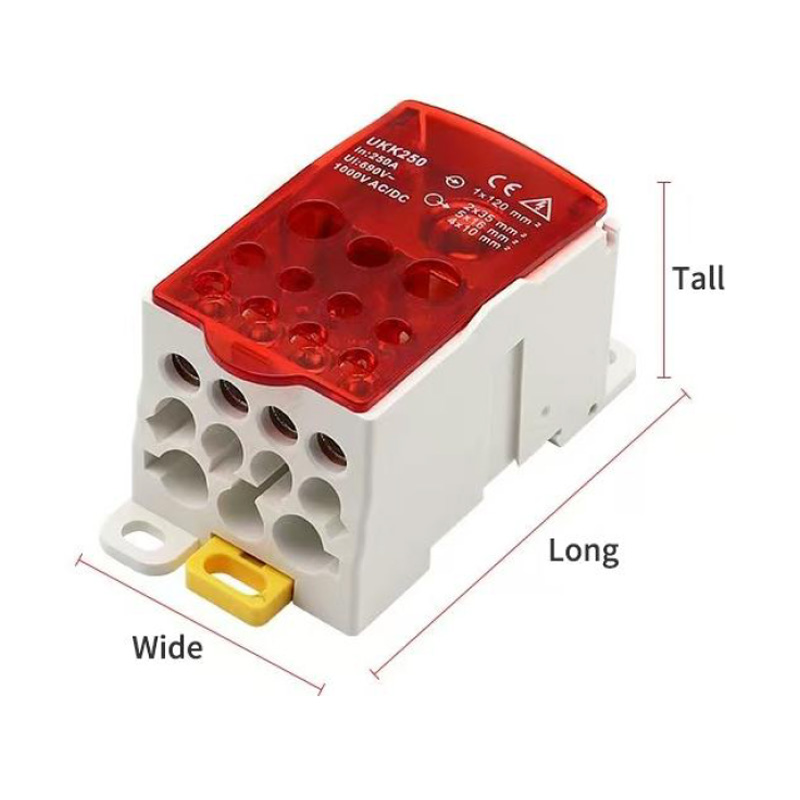

UKK Terminal

| PRODUCT NAME | ENTRYANDEXIT LINES | EXTERNAL DIMENSIONS | SQUARE OF WIRING |

| UKK80A | One in six out | 30X69X46 | Allthe way in6-16mm² Fourway outgoing line2.5-6mm² Two way outgoing line 2.5-16mm² |

| UKK125A | One in six out | 29X70X46 | All the way in 6-16mm² Allthe way in10-35mm² Six way outgoing line2.5-16mm² |

| UKK160A | One in six out | 29X70X46 | All the way in 6-16mm² All the way in 10-70mm² Six way outgoing line 2.5-16mm² |

| UKK250A | One ineleven out | 50X96X49 | All the way in 35-120mm² Two way incomingline 6-35mm² Five way outgoing line 2.5-16mm² Four way outgoing line 2.5-10mm² |

| UKK400A | One ineleven out | 50X96X49 | All the way in 95-185mm² Two way incomingline 6-35mm² Five way outgoing line 2.5-16mm² Four way outgoing line 2.5-10mm² |

| UKK500A | One ineleven out | 50X96X49 | All the way in3*15mm²-8*24mm² Two way incoming line6-35mm² Five way outgoing line2.5-16mm² Four way outgoing line 2.5-10mm² |

JTS2 Terminal

| Model | Hard wire range |

Current (A) |

L (mm) |

High (mm) |

W (mm) |

Hole count |

||||||||||||||||||||||||

| 1 in 1 out wiring terminal (copper nose type) |

4~35 | 250 | 78 | 63 | 21 | 0 | ||||||||||||||||||||||||

| 1 in 1 out wriring terminal (copper nose type) |

4~50 | 300 | 78 | 63 | 25 | 0 | ||||||||||||||||||||||||

| 1 in 1 out wriring terminal (copper nose type) |

10~90 | 500 | 78 | 63 | 30 | 0 | ||||||||||||||||||||||||

| 1 in 1 out wriring terminal | 4~16 | 150 | 60 | 45 | 21 | 1 | ||||||||||||||||||||||||

| 1 switch 2 way wiring terminal |

4~35 | 200 | 78 | 53 | 21 | 2 | ||||||||||||||||||||||||

| 1 switch 2 way wiring terminal (copper nose) |

4~35 | 200 | 78 | 63 | 21 | 2 | ||||||||||||||||||||||||

| 1 input and 4 output wiring terminal |

6~35 | 200 | 78 | 53 | 21 | 4 | ||||||||||||||||||||||||

| 1 input and 4 output wiring terminal (copper nose) |

6~35 | 200 | 78 | 63 | 21 | 4 | ||||||||||||||||||||||||

| 1 input and 4 output wiring terminal |

6~50 | 300 | 78 | 53 | 25 | 4 | ||||||||||||||||||||||||

| 1 input and 4 output wiring terminal (copper nose) |

6~50 | 300 | 78 | 63 | 25 | 4 | ||||||||||||||||||||||||

| 1 in 6 out wiring terminal | 4~50 | 300 | 78 | 53 | 25 | 6 | ||||||||||||||||||||||||

| 1 in 6 out wiring terminal (copper nose) |

4~90 | 500 | 78 | 63 | 30 | 6 | ||||||||||||||||||||||||

| 1 in 8 out wiring terminal | 4~50 | 500 | 78 | 63 | 30 | 8 | ||||||||||||||||||||||||

| 1 in 8 out wiring terminal (copper nose type) |

4~120 | 500 | 78 | 63 | 36 | 8 | ||||||||||||||||||||||||

| 1 in 9 out wiring terminal | 4~50 | 250 | 78 | 63 | 21 | 9 | ||||||||||||||||||||||||

| 1 in 9 out wiring terminal | 4~50 | 300 | 78 | 53 | 25 | 9 | ||||||||||||||||||||||||

| 1 in 9 out wiring terminal | 4~70 | 400 | 78 | 63 | 30 | 9 | ||||||||||||||||||||||||

| 1 in 12 out wiring terminal | 4~70 | 400 | 78 | 63 | 30 | 12 | ||||||||||||||||||||||||

| 1 in 12 out wiring terminal (copper nose type) |

4~70 | 400 | 78 | 63 | 30 | 12 | ||||||||||||||||||||||||

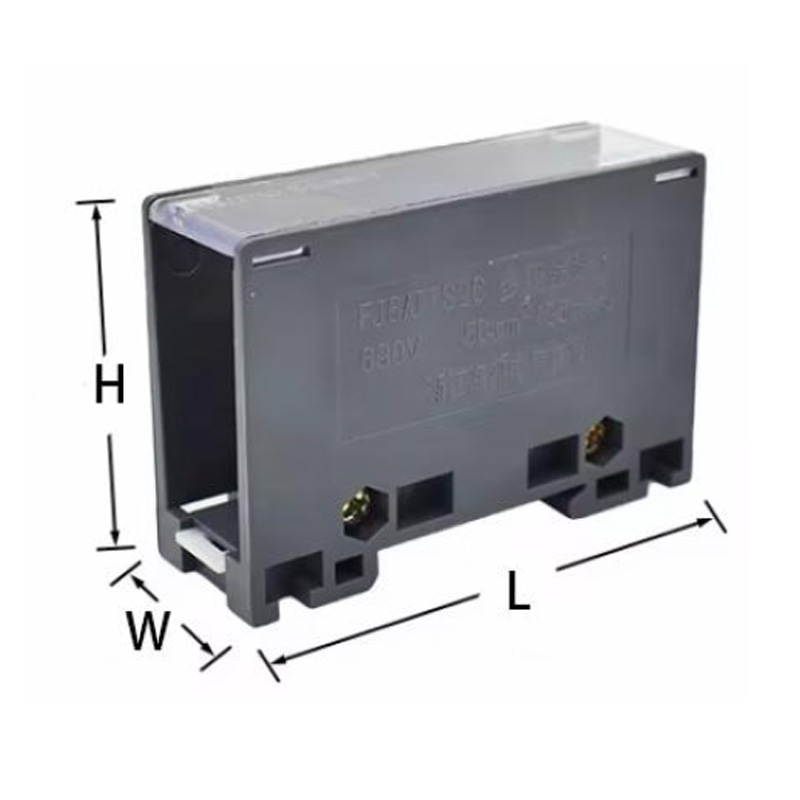

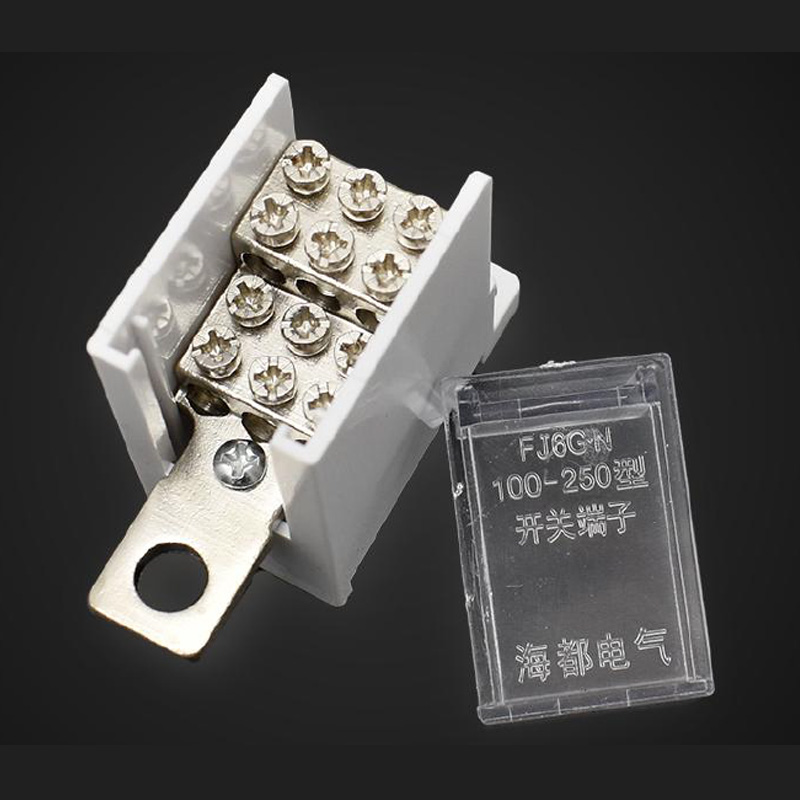

FJ6G Terminal

| Model | Conductor (m㎡) |

Hole Size Φ |

Long (mm) |

Wide (mm) |

High (mm) |

|||||||||||||||

| FJ6G/63/2x10 | 1.5-10 | / | 42 | 18 | 52 | |||||||||||||||

| FJ6G/63/4x10 | 1.5-10 | / | 42 | 18 | 52 | |||||||||||||||

| FJ6G/63/6x10 | 1.5-10 | / | 42 | 18 | 52 | |||||||||||||||

| FJ6G/63/9x10 | 1.5-4 | / | 42 | 18 | 52 | |||||||||||||||

| FJ6G/100/2x16 | 1.5-16 | 8.3 | 42 | 25 | 53 | |||||||||||||||

| FJ6G/100/3x16 | 1.5-16 | 8.3 | 42 | 28.6 | 53 | |||||||||||||||

| FJ6G/100/4x16 | 1.5-16 | 8.3 | 42 | 25 | 53 | |||||||||||||||

| FJ6G/100/6x16 | 1.5-16 | 8.3 | 42 | 28.6 | 53 | |||||||||||||||

| FJ6G/100/8x10 | 1.5-10 | 8.3 | 42 | 28.6 | 53 | |||||||||||||||

| FJ6G/100/9x16 | 1.5-16 | 8.3 | 42 | 28.6 | 53 | |||||||||||||||

| FJ6G/100/12x10 | 1.5-10 | 8.3 | 42 | 28.6 | 53 | |||||||||||||||

| FJ6G/250/2x16 | 1.5-16 | 8.5 | 42 | 25 | 53 | |||||||||||||||

| FJ6G/250/3x16 | 1.5-16 | 8.5 | 42 | 28.6 | 53 | |||||||||||||||

| FJ6G/250/4x16 | 1.5-16 | 8.5 | 42 | 25 | 53 | |||||||||||||||

| FJ6G/250/6x16 | 1.5-16 | 8.5 | 42 | 28.6 | 53 | |||||||||||||||

| FJ6G/250/8x10 | 1.5-10 | 8.5 | 42 | 28.6 | 53 | |||||||||||||||

| FJ6G/250/9x16 | 1.5-16 | 8.5 | 42 | 28.6 | 53 | |||||||||||||||

| FJ6G/250/12x10 | 1.5-10 | 8.5 | 50 | 28.6 | 53 | |||||||||||||||

| FJ6G/400/4x16 | 1.5-16 | 10.9 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/400/6x16 | 1.5-16 | 10.9 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/400/8x16 | 1.5-16 | 10.9 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/400/10x16 | 1.5-16 | 10.9 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/400/12x16 | 1.5-16 | 10.9 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/400/15x16 | 1.5-10 | 10.9 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/400/18x16 | 1.5-16 | 10.9 | 43 | 52 | 60 | |||||||||||||||

| FJ6G/600/4x16 | 1.5-16 | 12.3 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/600/6x16 | 1.5-16 | 12.3 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/600/8x16 | 1.5-16 | 12.3 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/600/10x16 | 1.5-16 | 12.3 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/600/12x10 | 1.5-1.0 | 12.3 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/600/16x10 | 1.5-1.0 | 12.3 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/600/18x10 | 1.5-1.0 | 12.3 | 43 | 44 | 60 | |||||||||||||||

| FJ6G/600/24x6 | 1.5-6 | 12.3 | 43 | 52 | 60 | |||||||||||||||

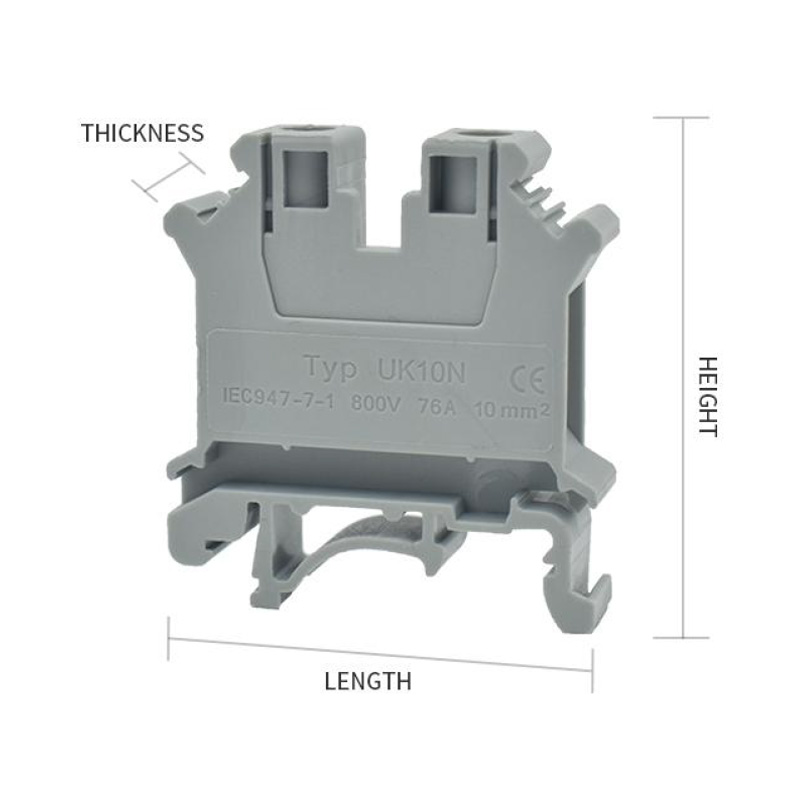

UK Terminal

| MODEL | ANNEALED COPPER mm |

SOLID COPPER mm |

CURRENT A |

VOLTAGE V |

LENGTH mm |

HEIGHT mm |

THICKNESS mm |

| UK1.5N | 0.2-1.5 | 0.2-2.5 | 32 | 690 | 42.5 | 41.5 | 4.2 |

| UK2.5B | 0.2-2.5 | 0.2-4 | 32 | 800 | 42.5 | 41.5 | 6.2 |

| UK3N | 0.2-2.5 | 0.2-4 | 32 | 800 | 42.5 | 46 | 5.2 |

| UK5N | 0.2-4 | 0.2-6 | 41 | 800 | 42.5 | 46 | 6.2 |

| UK6N | 0.2-6 | 0.2-10 | 57 | 800 | 42.5 | 46 | 8.2 |

| UK10N | 0.5-10 | 0.5-16 | 76 | 800 | 42.5 | 46 | 10.2 |

| UK16N | 0.75-18 | 0.75-25 | 101 | 800 | 42.5 | 46 | 12.2 |

| UK25N | 0.75-25 | 0.75-30 | 100 | 800 | 42.5 | 46 | 14.2 |

| UIK-35 | 0.75-35 | 0.75-50 | 150 | 800 | 56 | 51 | 15.5 |

| UKH50 | 16-50 | 16-50 | 150 | 1000 | 72 | 70 | 20.8 |

JF5 Wiring Terminal

| Model | Wire cross section (mm2) |

Current (A) |

Voltage (V) |

L (mm) |

H (mm) |

W (mm) |

Group |

| JF5-1.5/1 | 0.5~1.5 | 17.5 | 660 | 30 | 29 | 8 | 1 |

| JF5-1.5/2 | 0.5~1.5 | 17.5 | 660 | 30.5 | 30 | 19.3 | 2 |

| JF5-1.5/3 | 0.5~1.5 | 17.5 | 660 | 30.5 | 30 | 28.5 | 3 |

| JF5-1.5/5 | 0.5~1.5 | 17.5 | 660 | 30.5 | 30 | 46.5 | 5 |

| JF5-2.5/1 | 0.5~2.5 | 24 | 660 | 35 | 31 | 10 | 1 |

| JF5-2.5/2 | 0.5~2.5 | 24 | 660 | 36 | 31 | 24.5 | 2 |

| JF5-2.5/3 | 0.5~2.5 | 24 | 660 | 36 | 31 | 36 | 3 |

| JF5-2.5/5 | 0.5~2.5 | 24 | 660 | 36 | 31 | 59 | 5 |

| JF5-4/1 | 0.75~4 | 32 | 660 | 40 | 31 | 12.5 | 1 |

| JF5-4/2 | 0.75~4 | 32 | 660 | 40 | 32 | 27.5 | 2 |

| JF5-4/3 | 0.75~4 | 32 | 660 | 40 | 32 | 41 | 3 |

| JF5-4/5 | 0.75~4 | 32 | 660 | 40 | 32 | 68 | 5 |

| JF5-6/1 | 2.5~6 | 41 | 660 | 45 | 43 | 16 | 1 |

| JF5-6/2 | 2.5~6 | 41 | 660 | 45 | 43 | 33 | 2 |

| JF5-6/3 | 2.5-6 | 41 | 660 | 45 | 43 | 48 | 3 |

| JF5-6/5 | 2.5~6 | 41 | 660 | 45 | 43 | 79 | 5 |

| JF5-10/1 | 4~10 | 57 | 660 | 51 | 50 | 18 | 1 |

| JF5-10/2 | 4~10 | 57 | 660 | 51 | 50 | 36 | 2 |

| JF5-10/3 | 4~10 | 57 | 660 | 51 | 50 | 56 | 3 |

| JF5-10/5 | 4~10 | 57 | 660 | 51 | 50 | 92 | 5 |

| JF5-25/1 | 10~25 | 101 | 660 | 61 | 51 | 25 | 1 |

| JF5-25/2 | 10~25 | 101 | 660 | 61 | 51 | 48 | 2 |

| JF5-25/5 | 10~25 | 101 | 660 | 61 | 51 | 116 | 3 |

| JF5-50/1 | 10~50 | 150 | 660 | 70 | 56 | 30 | 5 |

| JF5-2.5R D | 0.5~2.5 | 24 | 660 | 60 | 55 | 11 | 1 |

| JF5-2.5S3 | 0.5~2.5 | 24 | 660 | 46 | 50 | 20 | 1 |

Search

Categories

-

Energy Measuring Terminal Block(314)

- Energy Measuring Joint Terminal Block(16)

- Polycarbonate Energy Measuring Terminal Block(24)

- Standard Wiring Energy Measuring Terminal Block(4)

- Transparent Shell Energy Measuring Terminal Block(6)

- Multifunctional Test Energy Measuring Terminal Block(10)

- Intelligent Safety Energy Measuring Terminal Block(6)

- Single-Phase Multi-Circuit Output Terminal Block(12)

- Self-Elevating Metering Box Terminal Block(7)

- One Household One-Meter Meter Box Dedicated Terminal Block(56)

- Three-Phase Metering Box Dedicated Terminal Block(24)

- Repeatable Grounding Line Terminal Block(20)

- Terminal Block for One-Inlet Multi-Outlet Metering Box(15)

- Closed Terminal Block(11)

- Heavy Current Terminal Block(48)

- Self-Boosting Terminal Block(5)

- Intelligent Self-Locking Terminal Block(3)

- Tool-Free Crimping Type Terminal Block(5)

- Wide Range of Wire Diameters Terminal Block(5)

- Combined Type Energy Measuring Terminal Block(37)

-

Switch Terminal Block(55)

- Pin-Type Incoming Line Switch Terminal Block(4)

- Multi-Way Connection Switch Terminal Block(4)

- Plug-pin Switch Terminal Block(7)

- Combined Type Switch Terminal Block(7)

- High Contact Cross Section Switch Terminal Block(7)

- Wide Range Switch Terminal Block(11)

- One Way in Switch Terminal Block(12)

- Equipped with Circuit Breaker Switch Terminal(3)

-

Heavy-current Terminal Block(631)

- Modular Building Block Terminal Block(156)

- Spherical Non-Destructive Crimp Terminal(120)

- Dual-Mode Connection Electrical Terminal(90)

- Anti-Electricity-Theft Terminal Block(74)

- Convenient Connection Terminal Block(12)

- High-Contact Section Terminal Block(12)

- Wide Range of Wire Diameters Neutral Line Terminal(9)

- Heavy-Current Neutral Line Terminal(9)

- Upper and Lower Rows of Neutral Terminal(2)

- Independent Neutral Line Terminal(7)

- Nose-Type Neutral Line Terminal(7)

- Rail Type Neutral Line Terminal(9)

- Fixed Neutral Line Terminal(12)

- Double Rail Assembly Electrical Terminal(19)

- Blue Jack-Up Terminal(6)

- Black Base Copper Bar Terminal(5)

- Compact Terminal Block(16)

- Precision Terminal Block(23)

- U-Shaped Harpoon Terminal(2)

- Grounding Metering Box Terminal Block(12)

- High-Performance Terminal Block(19)

- Multifunctional Terminal Block(10)

- Din Rail Terminal Block(76)

- Watt-hour Meter Connector(49)

-

Energy Meter Accessories(116)

-

-

Secure connections are essential for reliable electrical distribution, especially when installing a High-performance Terminal Bloc...

READ MORE -

For engineers and panel builders striving for both efficiency and reliability, wiring errors remain a persistent headache — even w...

READ MORE -

In modern electrical systems, a High-performance Terminal Block plays a critical role in ensuring secure and reliable connections ...

READ MORE -

When building or maintaining electrical systems, one frequently overlooked but critical factor is matching the conductor size to t...

READ MORE -

Effective electrical connections depend on more than simply matching cable sizes. Whether you’re securing a power conductor with a...

READ MORE

The UKK80A terminal block is a high-performance electrical power distribution device designed for environments requiring high voltage up to 690V IEC. It's rated for 80-85A current capacity, making it suitable for industrial, commercial, and energy sector applications.

Key Features:

· Material: Flame-retardant PA66 or PA Nylon shell and brass nickel-plated metal components for electrical safety and durability

· Connection Method: Screw connection for secure and reliable connections

· Mounting Type: DIN Rail NS 35 for easy installation

· Certifications: IEC 60947-7-1, UL, and ISO9001 for quality assurance

Specifications:

· Input: 1x16 mm²

· Output: 4x6 mm² and 2x16 mm²

· Dimensions: 30x69x49 mm or 70.85x30.05x45.5 mm (variations depending on supplier)

Applications:

· Industrial control panels

· Power distribution in commercial buildings

· High-voltage systems

Benefits:

· Convenient and economical power distribution solution

· High conductivity with electrical contacts

· Easy installation and maintenance with transparent cover for connection monitoring

How Does The Cost Of a Multifunctional Ukk80A Terminal Block Compare To Other Connector Types?

The cost of a UKK80A terminal block can vary depending on the supplier and quantity. According to Octopart, the price range for UKK80A terminal blocks from different distributors starts from around $849. Another supplier, Smico, offers the UKK80A terminal block at $0.15 per piece for bulk orders.

In comparison to other connector types, terminal blocks like UKK80A are often more cost-effective than splicing or soldering methods, especially for large-scale installations. Wago connectors, known for their ease of use and efficiency, may be more expensive than terminal blocks but offer advantages like tool-free installation and versatility.

Here's a rough estimate of the cost comparison:

· UKK80A Terminal Block: $0.15-$849 per piece, depending on supplier and quantity

· Wago Connectors: Generally more expensive than terminal blocks, with prices varying depending on the specific type and supplier

· Splicing: Cost-effective, with prices starting from a few cents for wire connectors and electrical tape

· Soldering: Requires investment in specialized equipment and skills, making it more expensive for small-scale applications

How Do You Determine The Correct Size Din Rail Distribution Box For Your Application?

Choosing the right size Din Rail Distribution Box for your application involves considering several factors, including:

· Current Rating: Ensure the terminal block can handle the current of your application. UKK80A terminal blocks have a rated current of 80A or 85A.

· Voltage Rating: Select a terminal block with a voltage rating that matches or exceeds your application's requirements. UKK80A terminal blocks typically have a rated voltage of 690V IEC.

· Number of Connections: Determine the number of input and output connections required for your application. UKK80A terminal blocks usually have one input and six output connections.

· Wire Size: Choose a terminal block that accommodates the wire size used in your application. UKK80A terminal blocks typically accept wire sizes ranging from 2.5mm² to 16mm².

Some popular Din Rail Distribution Box sizes include:

· UKK-80: 80A, 690V IEC, 1 input, 6 outputs, suitable for applications with moderate power requirements

· UKK-125: 125A, 690V IEC, 1 input, 7 outputs, ideal for applications with higher power demands

· UKK-250: 250A, 690V IEC, 1 input, multiple outputs, suitable for heavy-duty applications

· UKK-400: 400A, 690V IEC, 1 input, multiple outputs, designed for high-power applications

· UKK-500: 500A, 690V IEC, 1 input, multiple outputs, suitable for demanding applications

When selecting a Din Rail Distribution Box, consider factors like :

· Environmental Conditions: Ensure the terminal block can withstand the temperature, moisture, and exposure to chemicals in your application environment.

· Ease of Maintenance: Choose a terminal block with features like transparent covers or easy-to-access connections for simplified maintenance.

· Certifications and Compliance: Verify the terminal block meets relevant industry standards and certifications, such as IEC 60947-7-1.

By considering these factors and choosing the right size Din Rail Distribution Box, you can ensure reliable and efficient power distribution in your application.

English

English Español

Español عربى

عربى