Integrating wired connectivity into the era of automation and digital networking involves more than just traditional hardware. A H...

READ MOREHigh-Performance Terminal Block Manufacturer

High-Performance Terminal Blocks are professionally used for creating robust and highly reliable electrical connections in demanding applications. These terminal blocks are specifically designed to meet the stringent requirements of high-current, high-voltage, and high-frequency electrical systems, making them ideal for use in industrial, commercial, and heavy-duty environments where performance and reliability are critical.

These terminal blocks feature advanced materials and construction techniques that ensure secure and stable connections, even under operating conditions. They are capable of handling high current loads and maintaining low electrical resistance, minimizing energy loss.

High-Performance Terminal Blocks are currently a solution for managing electrical connections in high-demand environments. They simplify the wiring process by providing a compact and efficient connection point, enhance system reliability through their robust construction, and provide a safe and efficient way to manage high-current and high-voltage circuits. Their versatile design ensures compatibility with a wide range of applications, making them an essential component in modern electrical systems.

The double row design of these terminals allows for a higher density of connections in a compact space. This is particularly beneficial in environments where space is at a premium, such as in industrial control panels, telecommunications equipment, or any application that requires a high number of connections in a limited area.

Search

Categories

-

Energy Measuring Terminal Block(314)

- Energy Measuring Joint Terminal Block(16)

- Polycarbonate Energy Measuring Terminal Block(24)

- Standard Wiring Energy Measuring Terminal Block(4)

- Transparent Shell Energy Measuring Terminal Block(6)

- Multifunctional Test Energy Measuring Terminal Block(10)

- Intelligent Safety Energy Measuring Terminal Block(6)

- Single-Phase Multi-Circuit Output Terminal Block(12)

- Self-Elevating Metering Box Terminal Block(7)

- One Household One-Meter Meter Box Dedicated Terminal Block(56)

- Three-Phase Metering Box Dedicated Terminal Block(24)

- Repeatable Grounding Line Terminal Block(20)

- Terminal Block for One-Inlet Multi-Outlet Metering Box(15)

- Closed Terminal Block(11)

- Heavy Current Terminal Block(48)

- Self-Boosting Terminal Block(5)

- Intelligent Self-Locking Terminal Block(3)

- Tool-Free Crimping Type Terminal Block(5)

- Wide Range of Wire Diameters Terminal Block(5)

- Combined Type Energy Measuring Terminal Block(37)

-

Switch Terminal Block(55)

- Pin-Type Incoming Line Switch Terminal Block(4)

- Multi-Way Connection Switch Terminal Block(4)

- Plug-pin Switch Terminal Block(7)

- Combined Type Switch Terminal Block(7)

- High Contact Cross Section Switch Terminal Block(7)

- Wide Range Switch Terminal Block(11)

- One Way in Switch Terminal Block(12)

- Equipped with Circuit Breaker Switch Terminal(3)

-

Heavy-current Terminal Block(631)

- Modular Building Block Terminal Block(156)

- Spherical Non-Destructive Crimp Terminal(120)

- Dual-Mode Connection Electrical Terminal(90)

- Anti-Electricity-Theft Terminal Block(74)

- Convenient Connection Terminal Block(12)

- High-Contact Section Terminal Block(12)

- Wide Range of Wire Diameters Neutral Line Terminal(9)

- Heavy-Current Neutral Line Terminal(9)

- Upper and Lower Rows of Neutral Terminal(2)

- Independent Neutral Line Terminal(7)

- Nose-Type Neutral Line Terminal(7)

- Rail Type Neutral Line Terminal(9)

- Fixed Neutral Line Terminal(12)

- Double Rail Assembly Electrical Terminal(19)

- Blue Jack-Up Terminal(6)

- Black Base Copper Bar Terminal(5)

- Compact Terminal Block(16)

- Precision Terminal Block(23)

- U-Shaped Harpoon Terminal(2)

- Grounding Metering Box Terminal Block(12)

- High-Performance Terminal Block(19)

- Multifunctional Terminal Block(10)

- Din Rail Terminal Block(76)

- Watt-hour Meter Connector(49)

-

Energy Meter Accessories(116)

-

-

Secure connections are essential for reliable electrical distribution, especially when installing a High-performance Terminal Bloc...

READ MORE -

For engineers and panel builders striving for both efficiency and reliability, wiring errors remain a persistent headache — even w...

READ MORE -

In modern electrical systems, a High-performance Terminal Block plays a critical role in ensuring secure and reliable connections ...

READ MORE -

When building or maintaining electrical systems, one frequently overlooked but critical factor is matching the conductor size to t...

READ MORE -

Effective electrical connections depend on more than simply matching cable sizes. Whether you’re securing a power conductor with a...

READ MORE

Can High-Performance 2-Row Barrier Terminal Blocks Be Used in Automation and Control Systems?

High-performance 2-row barrier terminal blocks are a reliable choice for connecting wires in various electrical systems. In automation and control systems, where consistent connections are crucial, these terminal blocks can play an important role. Their design supports both safety and organized wiring, which are necessary in complex installations.

Organized Wiring Layout

Automation systems often involve a large number of input and output connections.

A 2-row barrier terminal block provides a neat arrangement where wires can be grouped and separated clearly.

This makes it easier to trace circuits, perform maintenance, and reduce installation errors.

Electrical Performance

These terminal blocks are designed to handle higher currents and voltages compared to smaller connectors.

Their screw or clamp mechanisms ensure that wires remain tightly secured, reducing the risk of loose connections.

Reliable current flow is essential in automation, where even a brief interruption can affect processes.

Durability and Protection

The “barrier” design refers to the molded insulating walls between terminals.

These barriers prevent short circuits by keeping conductors apart, even when wires are positioned closely.

This feature is particularly valuable in control systems where dense wiring is common.

Flexibility of Use

High-performance 2-row barrier terminal blocks are adaptable, allowing use with different wire gauges.

They can also be mounted on panels or printed circuit boards, offering installation flexibility for system designers.

2-row barrier terminal blocks can certainly be used in automation and control systems. They provide secure connections, maintain order in wiring layouts, and withstand the demands of continuous operation.

What Are the Differences in Size and Capacity Between Interconnect Terminal Blocks?

Interconnect terminal blocks are available in many variations to meet the needs of different electrical systems. Their size and capacity directly influence how they are applied, from small-scale electronics to heavy-duty industrial power distribution. Understanding these differences helps in choosing the right terminal block for a given project.

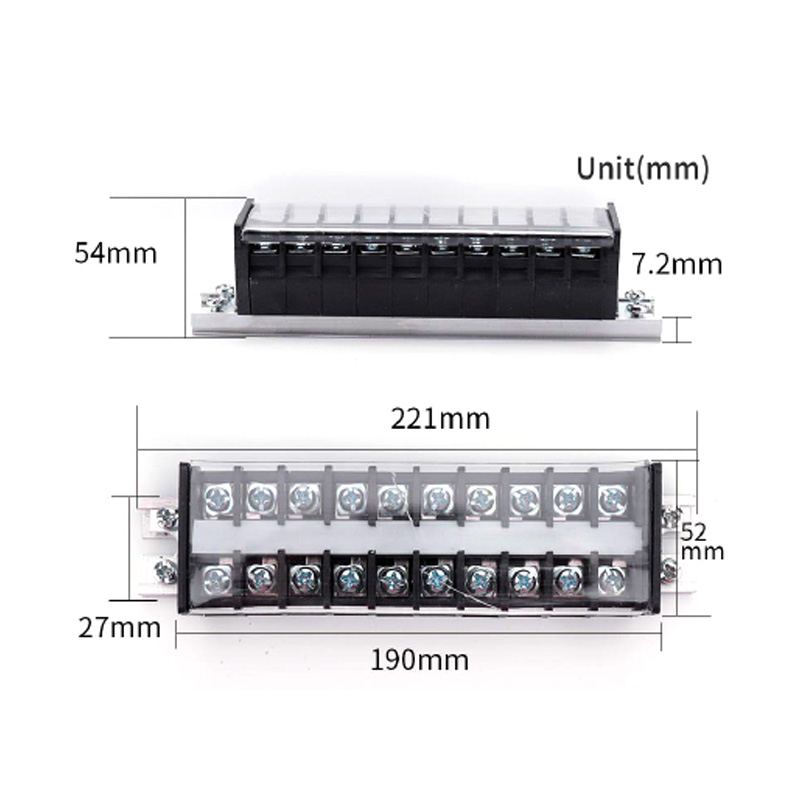

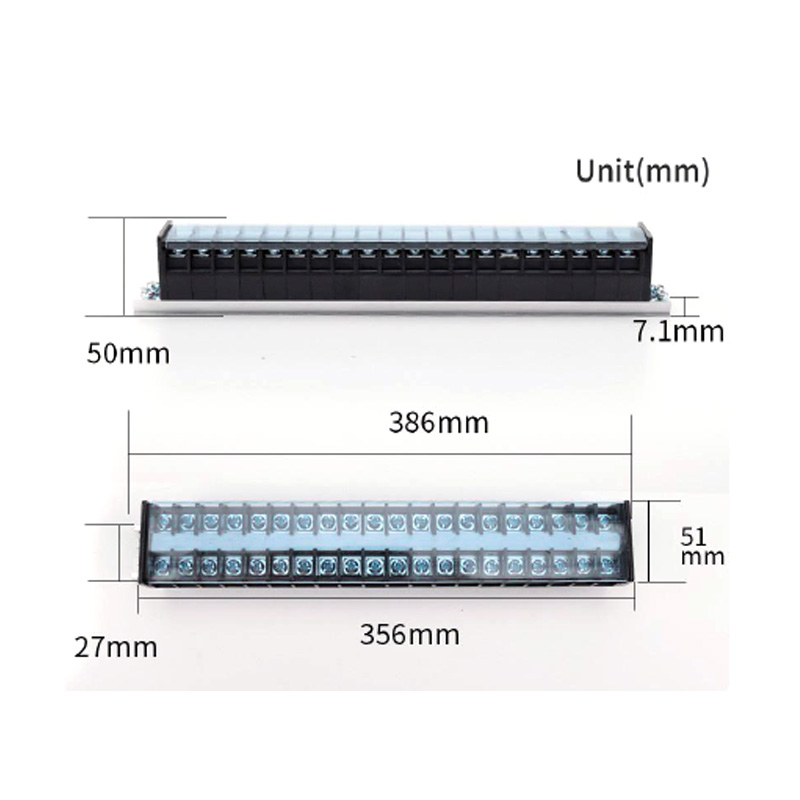

Physical Size Variations

Smaller interconnect terminal blocks are designed for compact circuits. They may measure only a few millimeters in width, allowing them to fit into space-limited enclosures.

Larger terminal blocks, sometimes several centimeters wide, are intended for power-heavy applications. They provide more surface area for wire entry and stronger clamping systems.

The size also affects how many terminals can be grouped together on a rail or panel.

Current and Voltage Capacity

Light-duty terminal blocks may be rated for currents under 10 amps and voltages under 250 volts, making them suitable for control signals and small devices.

Medium-capacity blocks often handle 20–50 amps with voltage ratings up to 600 volts, fitting the needs of commercial systems.

Heavy-duty interconnect blocks can handle currents above 100 amps and higher voltage ranges, often used in industrial power distribution.

Conductor Size Compatibility

Smaller blocks accept fine-gauge wires used for signals and low-power connections.

Larger blocks are designed for thicker wires that carry more current.

This flexibility allows system designers to match block size to the wire gauge required in a specific application.

Mounting Considerations

Compact blocks are often mounted on printed circuit boards.

Larger versions are usually DIN rail-mounted or fixed to panels, supporting mechanical strength and easier cable management.

Interconnect terminal blocks differ significantly in size and capacity depending on their intended application. Selecting the right type ensures not only safe operation but also efficiency in installation and long-term system reliability.

English

English Español

Español عربى

عربى