Integrating wired connectivity into the era of automation and digital networking involves more than just traditional hardware. A H...

READ MOREGrounding Metering Box Terminal Block Manufacturer

Grounding Metering Box Terminal Blocks are professionally used for reliable grounding and electrical metering connections in metering boxes and distribution systems. These terminal blocks are specifically designed to provide a secure and stable grounding point while also facilitating accurate metering of electrical energy, making them ideal for applications that require both safety and precise measurement.

These terminal blocks feature a robust design that ensures secure connections for grounding wires and metering circuits. They are engineered to handle the demands of electrical metering systems, with an insulation voltage of up to 690V and a rated voltage of 380V. The integrated grounding and metering functions allow for efficient management of electrical connections without the need for excessive wiring or additional components.

Grounding Metering Box Terminal Blocks are currently a reliable solution for managing grounding and metering connections in electrical systems. They simplify the installation process by combining multiple functions into a single unit, enhance system safety and reliability through secure grounding, and provide accurate metering capabilities. Their versatile design ensures compatibility with a wide range of metering boxes and distribution boards, making them an essential component in modern electrical installations.

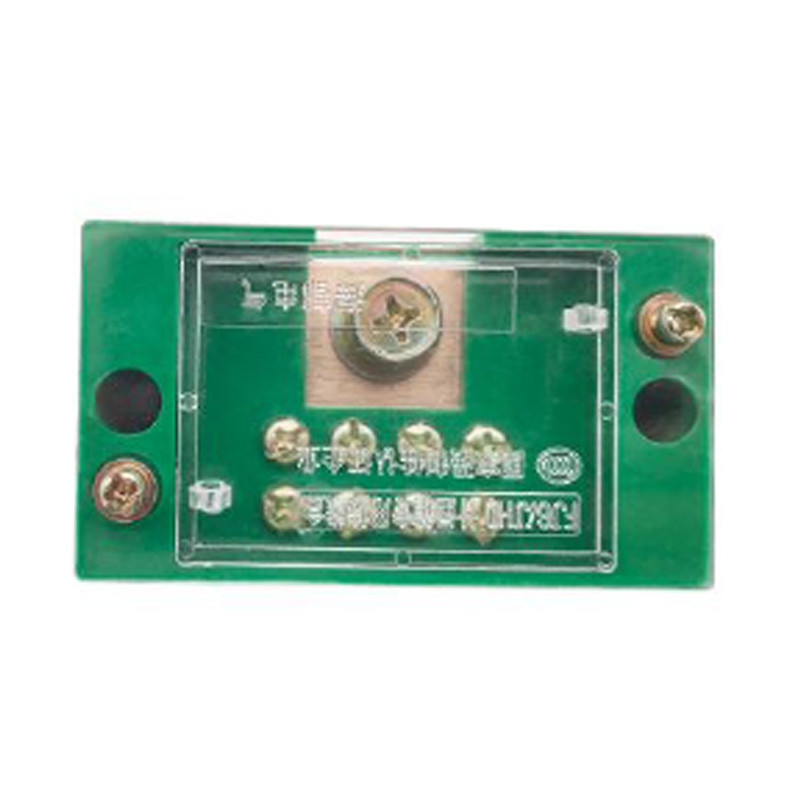

FJ6J JHD-1-2-3 One In Four Out Grounding Metering Box Junction Box

Model: one in four out

Type: 200A

Voltage: 660V

Size: 80×45×33mm

Incoming line: 2.5~10mm²

Outgoing line: 2.5~35mm²

Hole spacing: 68mm

Materials: polycarbonate/brass

FJ6J JHD-1-2-3 One In Six Out Grounding Metering Box Junction Box

Model: one in six out

Type: 200A

Voltage: 660V

Size: 80X45×33mm

Incoming line: 2.5~10mm²

Outgoing line: 2.5~35mm²

Hole spacing: 68mm

Materials: polycarbonate/brass

FJ6J JHD-1-2-3 Two In Six Out Metering Box Junction Box

Model: two in six out

Type: 200A

Voltage: 660V

Size: 80×45×33mm

Incoming line: 2.5~10mm²

Outgoing line: 2.5~50mm²

Hole spacing: 68mm

Materials: polycarbonate\brass

FJ6J JHD-1-2-3 two in eight out Grounding Metering Box Junction Box

Model: two in eight out

Type: 200A

Voltage: 660V

Size: 99×45×33mm

Incoming line: 2.5~10mm²

Outgoing line: 2.5~70mm²

Hole spacing: 86mm

Materials: polycarbonate(brass)

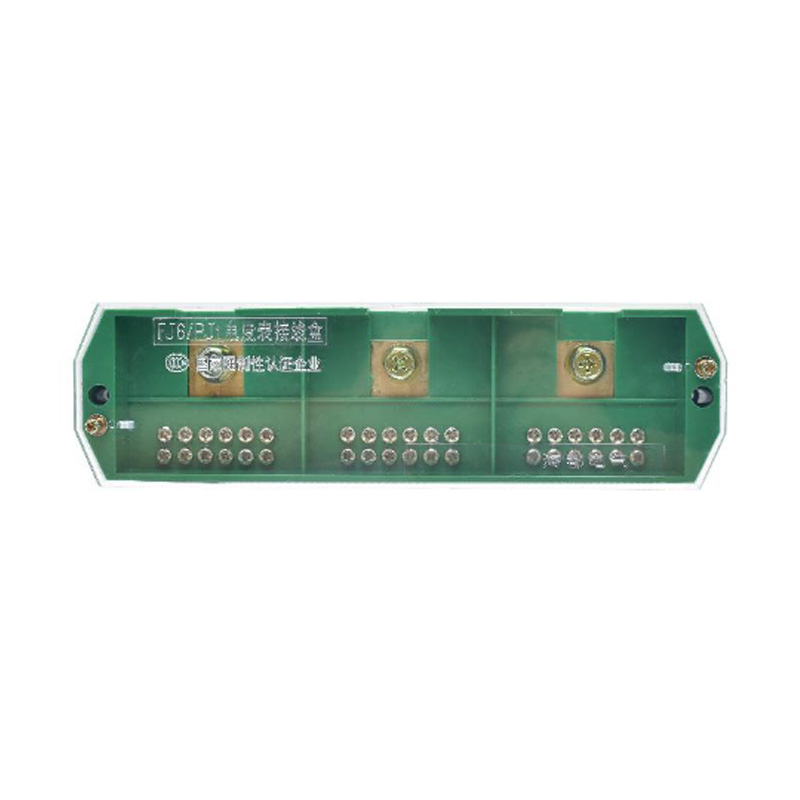

FJ6J JHD-1-2-3 Three In Twelve Out Grounding Metering Box Junction Box

Model: three in twelve out

Type: 400A

Voltage: 660V

Size: 137×46x36mm

Incoming line: 2.5~10mm²

Outgoing line: 2.5~70mm²

Hole spacing: 124mm

Materials: polycarbonate|brass

FJ6J JHD-1-2-3 Three In Eighteen Out Grounding Metering Box Junction Box

Model: three in eighteen out

Type: 400A

Voltage: 660V

Size: 235X63X36mm

Incoming line: 2.5~10mm²

Outgoing line: 2.5~70mm²

Hole spacing: 218mm

Materials: polycarbonate|brass

FJ6J JHD-1-2-3 Two In Twelve Out Grounding Metering Box Junction Box

Model: two in twelve out

Type: 200A

Voltage: 660V

Size: 120×45x36mm

Incoming line: 2.5~10mm²

Outgoing line: 2.5~70mm²

Hole spacing: 108mm

Materials: polycarbonate|brass

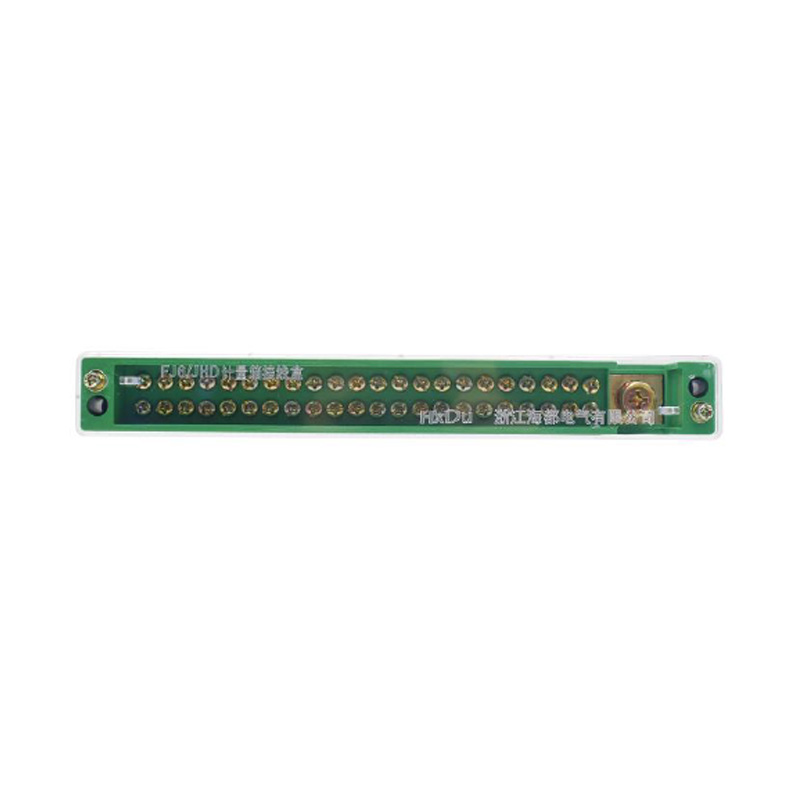

FJ6J JHD-1-2-3 Two In Twenty-Six Out Grounding Metering Box Junction Box

Model: two in twenty-six out

Type: 400A

Voltage: 660V

Size: 182×55×36mm

Incoming line: 2.5~10mm²

Outgoing line: 2.5~70mm²

Hole spacing: 170mm

Materials: polycarbonate|brass

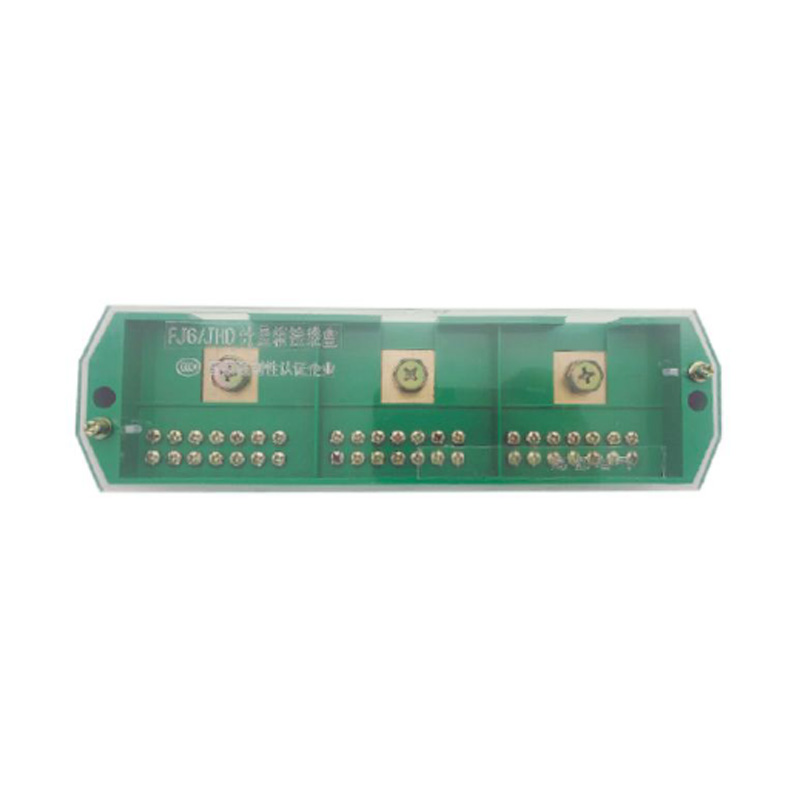

FJ6J JHD-1-2-3 Three In Six Out Grounding Metering Box Junction Box

Model: three in six out

Type: 400A

Voltage: 660V

Size: 119×55×36mm

Incoming line: 2.5~10mm²

Outgoing line: 2.5~50mm²

Hole spacing: 107mm

Materials: polycarbonate(brass)

FJ6J JHD-1-2-3 Three In Twenty One Out Grounding Metering Box Junction Box

Model: three in twenty one out

Type: 400A

Voltage: 660V

Size: 235X63X36mm

Incoming line: 2.5~10mm²

Outgoing line: 2.5~70mm²

Hole spacing: 218mm

Materials: polycarbonate(brass)

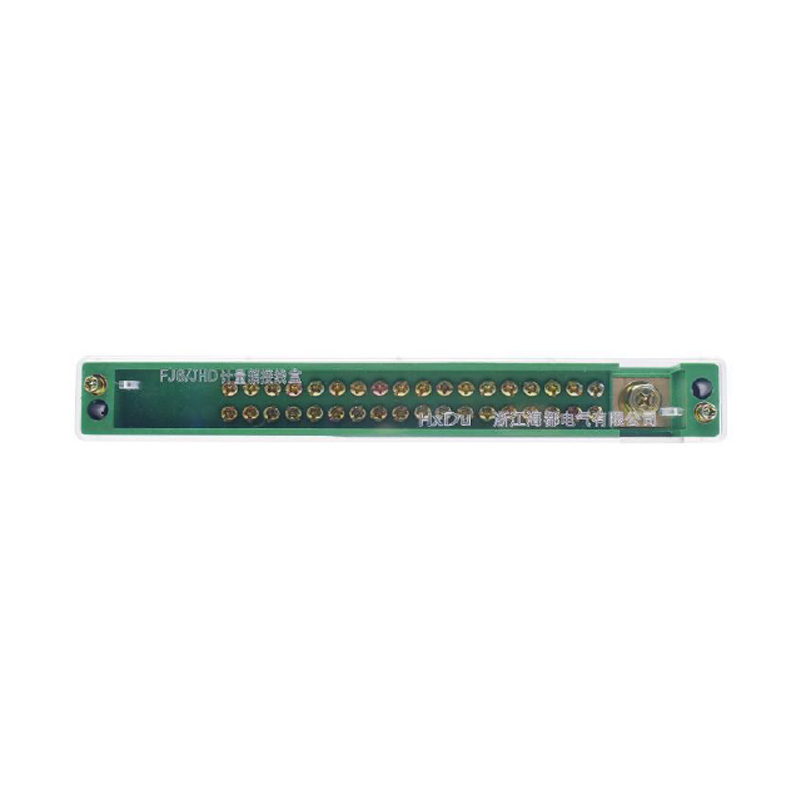

FJ6J JHD-1-2-3 One In Eighteen Out Grounding Metering Box Junction Box

Model: one in eighteen out

Type: 200A

Voltage: 660V

Size: 230×26×36mm

Incoming line: 2.5~10mm²

Outgoing line: 2.5~50mm²

Hole spacing: 218mm

Materials: polycarbonate/brass

FJ6J JHD-1-2-3 One In Twenty Two Out Grounding Metering Box Junction Box

Model: one in twenty two out

Type: 400A

Voltage: 660V

Size: 230×26×36mm

Incoming line: 2.5~10mm²

Outgoing line: 2.5~50mm²

Hole spacing: 218mm

Materials: polycarbonate(brass)

Search

Categories

-

Energy Measuring Terminal Block(314)

- Energy Measuring Joint Terminal Block(16)

- Polycarbonate Energy Measuring Terminal Block(24)

- Standard Wiring Energy Measuring Terminal Block(4)

- Transparent Shell Energy Measuring Terminal Block(6)

- Multifunctional Test Energy Measuring Terminal Block(10)

- Intelligent Safety Energy Measuring Terminal Block(6)

- Single-Phase Multi-Circuit Output Terminal Block(12)

- Self-Elevating Metering Box Terminal Block(7)

- One Household One-Meter Meter Box Dedicated Terminal Block(56)

- Three-Phase Metering Box Dedicated Terminal Block(24)

- Repeatable Grounding Line Terminal Block(20)

- Terminal Block for One-Inlet Multi-Outlet Metering Box(15)

- Closed Terminal Block(11)

- Heavy Current Terminal Block(48)

- Self-Boosting Terminal Block(5)

- Intelligent Self-Locking Terminal Block(3)

- Tool-Free Crimping Type Terminal Block(5)

- Wide Range of Wire Diameters Terminal Block(5)

- Combined Type Energy Measuring Terminal Block(37)

-

Switch Terminal Block(55)

- Pin-Type Incoming Line Switch Terminal Block(4)

- Multi-Way Connection Switch Terminal Block(4)

- Plug-pin Switch Terminal Block(7)

- Combined Type Switch Terminal Block(7)

- High Contact Cross Section Switch Terminal Block(7)

- Wide Range Switch Terminal Block(11)

- One Way in Switch Terminal Block(12)

- Equipped with Circuit Breaker Switch Terminal(3)

-

Heavy-current Terminal Block(631)

- Modular Building Block Terminal Block(156)

- Spherical Non-Destructive Crimp Terminal(120)

- Dual-Mode Connection Electrical Terminal(90)

- Anti-Electricity-Theft Terminal Block(74)

- Convenient Connection Terminal Block(12)

- High-Contact Section Terminal Block(12)

- Wide Range of Wire Diameters Neutral Line Terminal(9)

- Heavy-Current Neutral Line Terminal(9)

- Upper and Lower Rows of Neutral Terminal(2)

- Independent Neutral Line Terminal(7)

- Nose-Type Neutral Line Terminal(7)

- Rail Type Neutral Line Terminal(9)

- Fixed Neutral Line Terminal(12)

- Double Rail Assembly Electrical Terminal(19)

- Blue Jack-Up Terminal(6)

- Black Base Copper Bar Terminal(5)

- Compact Terminal Block(16)

- Precision Terminal Block(23)

- U-Shaped Harpoon Terminal(2)

- Grounding Metering Box Terminal Block(12)

- High-Performance Terminal Block(19)

- Multifunctional Terminal Block(10)

- Din Rail Terminal Block(76)

- Watt-hour Meter Connector(49)

-

Energy Meter Accessories(116)

-

-

Secure connections are essential for reliable electrical distribution, especially when installing a High-performance Terminal Bloc...

READ MORE -

For engineers and panel builders striving for both efficiency and reliability, wiring errors remain a persistent headache — even w...

READ MORE -

In modern electrical systems, a High-performance Terminal Block plays a critical role in ensuring secure and reliable connections ...

READ MORE -

When building or maintaining electrical systems, one frequently overlooked but critical factor is matching the conductor size to t...

READ MORE -

Effective electrical connections depend on more than simply matching cable sizes. Whether you’re securing a power conductor with a...

READ MORE

How Does a Grounding Metering Box Terminal Block Withstand Electrical Stress and Vibration?

Grounding metering box terminal blocks are engineered to perform under demanding conditions. Their durability and performance can be understood through the following points:

Material Strength

Conductive parts are often made from copper or copper alloys.

These metals are chosen for their conductivity and ability to handle electrical stress without significant degradation.

Protective coatings, such as tin or nickel plating, further extend lifespan by resisting corrosion and oxidation.

Insulating Housing

The outer body is usually crafted from flame-retardant polymers.

These plastics provide both electrical insulation and thermal resistance.

They prevent accidental contact with live parts and maintain integrity during prolonged exposure to current flow.

Secure Clamping System

Screw-type or spring-type clamps ensure that wires remain firmly in place.

A tight grip minimizes the risk of loose connections, which could otherwise cause sparking or heating.

Resistance to Vibration

Mechanical vibration is common in industrial setups.

Spring-loaded designs apply constant pressure, preventing wires from loosening.

This design feature helps maintain stability even when equipment is in motion.

In essence, grounding metering box terminal blocks achieve durability through a combination of material quality, insulation, and reliable clamping designs that resist both electrical and mechanical stresses.

What Are the Main Components of a Quick Push Terminal Block?

Quick push terminal blocks are designed for fast and reliable connections. They can be understood by examining their main parts:

Housing

Made from thermoplastic or polyamide materials.

Provides insulation, preventing accidental electrical contact.

Designed to withstand heat and mechanical stress.

Spring Clamp Mechanism

The core feature of quick push terminals.

Constructed from stainless steel or similar resilient metals.

Applies constant pressure to the wire once inserted, eliminating the need for screws.

Ensures reliable connections even after multiple insertions.

Conductive Pathway

Made of copper or copper-alloy for conductivity.

Often coated with tin or nickel to resist corrosion and maintain low contact resistance.

Provides a stable electrical path between wires.

Marking and Identification

Many blocks come with labels, numbering, or color coding.

These features simplify wiring organization and reduce installation mistakes.

Especially useful in complex control panels or industrial wiring setups.

Together, these components make the quick push terminal block a convenient, safe, and efficient option for modern electrical systems.

What Is the Service Life of a Terminal Wiring Connector?

Terminal wiring connectors are built for long-term use. Their service life depends on several contributing factors:

Typical Lifespan Range

Quality connectors generally last 10 to 20 years in standard conditions.

Durability depends on material quality and proper installation.

Conductive Materials

Made from copper or brass, known for electrical stability.

Protective coatings, such as tin plating, reduce oxidation and ensure consistent performance over time.

Insulating Housing

Constructed from heat- and moisture-resistant polymers.

Protects the conductive elements from environmental stress.

Environmental Factors

Connectors in indoor, climate-controlled environments last longer.

Outdoor or industrial conditions (humidity, dust, vibration, or high heat) may shorten service life if the connector is not designed for such settings.

Maintenance and Handling

Proper installation is crucial: wires must be fully inserted and securely clamped.

Periodic inspection helps detect signs of wear or loosening early.

Designs with anti-vibration features further extend service life in mechanical environments.

English

English Español

Español عربى

عربى