Integrating wired connectivity into the era of automation and digital networking involves more than just traditional hardware. A H...

READ MOREEnergy Meter Accessories Company

Energy Meter Accessories are an essential component in the field of energy management. These accessories are designed to complement and enhance the functionality of energy meters, which are used to measure the consumption of electrical energy. By providing additional features and functionalities, energy meter accessories ensure that energy meters operate at peak performance, thereby improving the accuracy and reliability of energy measurement.

1. Enhanced Accuracy and Precision:

One of the primary selling points of energy meter accessories is their ability to increase the precision of energy measurement. Accessories such as current and voltage transformers can help in accurately transforming high voltages and currents into values that can be measured by the energy meter. This ensures that the energy consumption data is reliable and accurate, which is crucial for billing purposes and energy management strategies.

2. Durability and Longevity:

Energy meter accessories are designed to withstand harsh environmental conditions and the wear and tear of continuous operation. They are made from high-quality materials that resist corrosion, wear, and environmental factors such as temperature fluctuations and humidity. This durability ensures that the accessories maintain their performance over a long period, reducing the need for frequent replacements and less maintenance costs.

3. Compatibility and Versatility:

A significant advantage of energy meter accessories is their compatibility with a wide range of energy meters and systems. This versatility allows for easy integration into existing infrastructure without the need for significant modifications or upgrades. Whether it's a small residential setup or a large industrial complex, energy meter accessories can be adapted to fit various configurations and requirements.

4. Improved Safety Features:

Safety is a important concern in electrical installations, and energy meter accessories are designed with this in mind. They often include features such as surge protection, which guards against voltage spikes that could damage the energy meter or connected equipment. Additionally, the accessories may have built-in mechanisms to prevent electrical faults or short circuits, thus enhancing the overall safety of the system.

5. Data Logging and Analysis Capabilities:

Some advanced energy meter accessories come with data logging capabilities, allowing for the collection and analysis of energy consumption data over time. This feature is particularly valuable for businesses and utilities that need to monitor and analyze their energy usage patterns for cost optimization and efficiency improvements.

6. Compliance with International Standards:

Energy meter accessories are manufactured to comply with international standards such as IEC, ANSI, and others. This ensures that the accessories meet the high quality and safety benchmarks, providing users with confidence in their performance and reliability.

7. Energy Efficiency and Cost Savings:

By ensuring accurate energy measurement, energy meter accessories indirectly contribute to energy efficiency and cost savings. Accurate data allows users to identify areas of high energy consumption and implement measures to reduce waste, thus significant savings over time.

In summary, energy meter accessories offer a range of benefits that enhance the performance of energy meters. From improved accuracy and precision to durability and compatibility, these accessories are vital for ensuring reliable energy measurement and management. As the demand for efficient energy usage and smart grid technologies grows, the role of energy meter accessories becomes increasingly important in supporting these advancements.

Nylon Wire Cap

| PRODUCT NAME | Crimping Cap CE-1 |

| APPLICABLECABLES | Both Soft And Hard Cables Are Acceptable |

| PRODUCTMATERIAL | Plastic Shell And Aluminum Inner Ring |

| WIRING RANGE | Two 1.0mm² Wire |

| PRODUCT NAME | Crimping Cap CE-2 |

| APPLICABLECABLES | Both Soft And Hard Cables Are Acceptable |

| PRODUCTMATERIAL | Plastic Shell And Aluminum Inner Ring |

| WIRING RANGE | Two 1.5mm² Wire |

| PRODUCT NAME | Crimping Cap CE-2 |

| APPLICABLECABLES | Both Soft And Hard Cables Are Acceptable |

| PRODUCTMATERIAL | Plastic Shell And Aluminum Inner Ring |

| WIRING RANGE | Two 2.5mm² Wire |

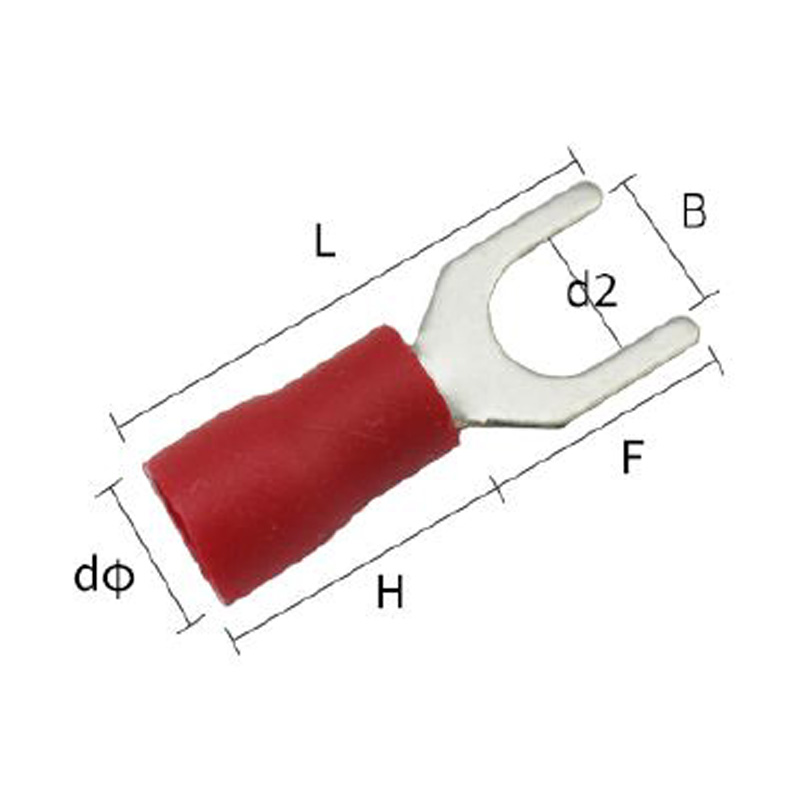

Cord End Terminal

PRODUCT NAME: COLD PRESS TERMINAL

PRODUCT SERIES: SV/RV SERIER

CONDUCTOR MATERIAL: COPPERCORE(EXTERNALTINNING)

INSULATING MATERIAL : FLAME RETARDANT PVC

CONNECTION MODE: EUROPEAN-STYLE CONNECTION

PECULIARITY: INSULATION/DUST AND CORROSION RESISTANCE

| PRODUCT MODEL | BOLTNUMBER | D2 mm² | B (mm) |

L (mm) |

H (mm) |

DФ mm² |

INSTRUCTIONS |

| RV 1.25-3 | #4 | 3.2 | 5.6 | 17.8 | 10 | 4.3 | Traverse section: 0.5-1.5mm2 American wire gauge 22-16 Electric current Imax=19A material: copper |

| RV 1.25-3.2 | #4 | 3.4 | 5.6 | 17.8 | |||

| RV 1.25-3.5 | #6 | 3.7 | 5.6 | 17.8 | |||

| RV 1.25-3.5M | #6 | 3.7 | 6.6 | 20.1 | |||

| RV 1.25-3.5L | #6 | 4.3 | 8.0 | 21.5 | |||

| RV 1.25-3.7 | #6 | 3.9 | 5.7 | 17.8 | |||

| RV 1.25-3.7M | #6 | 3.9 | 6.6 | 20.1 | |||

| RV 1.25-3.7L | #6 | 3.9 | 8.0 | 21.5 | |||

| RV 1.25-4 | #8 | 4.1 | 6.5 | 18.1 | |||

| RV 1.25-4L | #8 | 4.3 | 8.0 | 21.5 | |||

| RV 1.25-5 | #10 | 5.1 | 7.8 | 20.5 | |||

| RV 1.25-5L | #10 | 5.3 | 9.8 | 23.0 | |||

| RV 1.25-6 | 1/4 | 6.4 | 11.6 | 26.5 | |||

| RV 1.25-8 | 5/16 | 8.3 | 11.6 | 26.5 | |||

| RV 1.25-10 | 3/8 | 10.4 | 13.6 | 31.6 | |||

| RV 1.25-12 | 1/2 | 13 | 19.2 | 36.0 | |||

| RV 2-3 | #4 | 3.0 | 5.6 | 17.8 | 10 | 4.8 | Traversesection: 1.25-2.5mm2 Americanwiregauge 16-14 Electriccurrent Imax=24A material: copper |

| RV 2-3.2 | #4 | 3.2 | 5.6 | 17.8 | |||

| RV 2-3.5 | #6 | 3.7 | 57 | 17.8 | |||

| RV 2-3.5M | #6 | 3.7 | 6.6 | 21.0 | |||

| RV2-3.5L | #6 | 4.3 | 8.5 | 22.5 | |||

| RV 2-3.7 | #6 | 4.3 | 5.6 | 17.8 | |||

| RV 2-3.7M | #6 | 4.3 | 6.6 | 21.0 | |||

| RV 2-3.7L | #6 | 4.3 | 8.5 | 22 | |||

| RV 2-4 | #8 | 4.1 | 6.5 | 18.5 | |||

| RV 2-4L | #8 | 4.3 | 8.5 | 22.5 | |||

| RV 2-5 | #10 | 5.3 | 8.5 | 21.5 | |||

| RV 2-5L | #10 | 5.3 | 9.5 | 21.5 | |||

| RV 2-6 | 1/4 | 6.3 | 11.5 | 25.5 | |||

| RV 2-8 | 5/16 | 8.4 | 12.0 | 27.6 | |||

| RV 2-10 | 3/8 | 10.5 | 13.6 | 30.2 | |||

| RV 2-12 | 1/2 | 13.0 | 19.2 | 36.5 | |||

| PRODUCT MODEL | BOLTNUMBER | D2 mm² | B (mm) |

L (mm) |

H (mm) |

DФ mm² |

INSTRUCTIONS |

| SV 1.25-3 | #4 | 3.2 | 5.7 | 21.2 | 10 | 4.3 | Traverse section: 0.5-1.5mm2 American wire gauge 22-16 Electric current Imax=19A material: copper |

| SV 1.25-3.2 | #4 | 3.2 | 5.7 | 21.2 | |||

| SV 1.25-3.5 | #6 | 3.7 | 5.7 | 21.2 | |||

| SV 1.25-3.5L | #6 | 3.7 | 6.4 | 21.2 | |||

| SV 1.25-3.7 | #6 | 3.7 | 6.4 | 21.2 | |||

| SV 1.25-4 | #8 | 4.3 | 6.4 | 21.2 | |||

| SV 1.25-4M | #8 | 4.3 | 7.2 | 21.2 | |||

| SV 1.25-4L | #8 | 4.3 | 8.1 | 21.2 | |||

| SV 1.25-5 | #10 | 5.3 | 8.1 | 21.2 | |||

| SV 1.25-5L | #10 | 5.3 | 9.5 | 21.2 | |||

| SV 1.25-6 | 1/4 | 6.4 | 9.5 | 21.2 | |||

| SV 1.25-6L | 1/4 | 6.4 | 12 | 27.2 | |||

| SV 1.25-8 | 5/16 | 8.5 | 14 | 29 | |||

| SV 2-3 | #4 | 3.2 | 5.7 | 21.2 | 10 | 4.9 | Traverse section: 1.5-2.5mm2 American wire gauge 16-14 Electric current Imax=27A material: copper |

| SV 2-3.5 | #6 | 3.7 | 5.7 | 21.2 | |||

| SV 2-3.5L | #6 | 3.7 | 6.2 | 21.2 | |||

| SV 2-4 | #8 | 4.3 | 6.4 | 21.2 | |||

| SV 2-4M | #8 | 4.3 | 7.2 | 21.2 | |||

| SV 2-4L | #8 | 4.3 | 8.1 | 21.2 | |||

| SV 2-5 | #10 | 5.3 | 8.1 | 21.2 | |||

| SV 2-5L | #10 | 5.3 | 9.5 | 21.2 | |||

| SV 2-6 | 1/4 | 6.4 | 9.5 | 21.2 | |||

| SV 2-6L | 1/4 | 6.4 | 12 | 27.2 | |||

| SV 2-8 | 5/16 | 8.5 | 14 | 29 | |||

| SV 3.5-3 | #4 | 3.2 | 5.7 | 24.8 | 13 | 6.2 | Traverse section: 2.5~4mm2 American wire gauge 14-12 Electric current Imax=37A material: copper |

| SV 3.5-3.2 | #4 | 3.2 | 5.7 | 24.8 | |||

| SV 3.5-4 | #8 | 4.3 | 8.0 | 24.8 | |||

| SV 3.5-5 | #10 | 5.3 | 8.0 | 24.8 | |||

| SV 3.5-6 | 1/4 | 6.4 | 12 | 28 | |||

| SV 3.5-8 | 5/16 | 8.2 | 13.8 | 31.1 | |||

| SV 5.5-3.5 | #6 | 3.7 | 8.3 | 25 | 13 | 6.7 | Traverse section: 4~6mm2 American wire gauge 12-10 Electric current Imax=48A material: copper |

| SV 5.5-4 | #8 | 4.3 | 8.3 | 25 | |||

| SV 5.5-4L | #8 | 4.3 | 9.0 | 25.2 | |||

| SV 5.5-5 | #10 | 5.3 | 9.0 | 25.2 | |||

| SV 5.5-6 | 1/4 | 6.4 | 9.0 | 25.2 | |||

| SV 5.5-6L | 1/4 | 6.4 | 12.0 | 31.2 | |||

| SV 5.5-8 | 5/16 | 8.4 | 14.0 | 30 | |||

PRODUCT NAME: SHEET INSULATED SEGMENT

PRODUCT SERIES: DBV SERIER

CONDUCTOR MATERIAL: ORICHALCUM

INSULATING MATERIAL : PANYLON MATERIAL

CONNECTION MODE: BOTTOM CONNECTION

PECULIARITY: GOOD CONDUCTION AND EASY WIRING

| PRODUCT MODEL | COLOUR | F mm² |

B (mm) |

L (mm) |

H (mm) |

DФ mm² |

INSTRUCTIONS |

| RV 1.25-10 | 10 | 2.3 | 20 | 10 | 4.3 | Traverse section:0.5~1.5mm2 (American wire gauge 22-16) Electric current : Imax=19A Material thickness:0.75mm |

|

| RV 1.25-14 | RED | 14 | 3.0 | 24 | |||

| RV 1.25-18 | 18 | 2.2 | 28 | ||||

| RV 2-10 | 9 | 2.4 | 19 | 10 | 4.9 | Traverse section:1.5~2.5mm2 (American wire gauge 16-14) Electric current :Imax=27A Material thickness:0.8mm |

|

| RV 2-14 | BLUE | 14 | 2.4 | 24 | |||

| RV 2-18 | 18 | 2.2 | 28 | ||||

| RV 5.5-10 | 10 | 2.8 | 23 | 13 | 5.6 | Traverse section:4~6mm2 (American wire gauge 12-10) Electric current:Imax=48A Material thickness:1.0mm |

|

| RV 5.5-14 | YELLOW | 14 | 4.5 | 27 | |||

| RV 5.5-18 | 18 | 4.5 | 31 | ||||

Connector Insulated Cable

| Insert Model |

Quantities | Suitable Wire Diamete r(m ㎡) |

Material | Sheath Type |

Quantities | Suitable Wire Diameter (m ㎡) |

Colour | |||||||||||||||||||||||||||||||

| C45-1.5 | 40 | 1.5 | Copper galvanized |

V1.5 | 40 | 1.5 | Red | |||||||||||||||||||||||||||||||

| C45_2.5 | 40 | 2.5 | V2.5 | 40 | 2.5 | Blue | ||||||||||||||||||||||||||||||||

| C45_4 | 20 | 4 | V4 | 20 | 4 | Black | ||||||||||||||||||||||||||||||||

| C45-6 | 20 | 6 | V6 | 20 | 6 | Yellow | ||||||||||||||||||||||||||||||||

| C45-10 | 10 | 10 | V10 | 10 | 10 | Red | ||||||||||||||||||||||||||||||||

FRD Cable Terminal

| Model | bΦ (mm) |

L (mm) |

F (mm) |

H (mm) |

DΦ (mm) |

|||||||||||||

| MPD 1.25- 156 |

4 | 21 | 11 | 10 | 1.7 | |||||||||||||

| MPD 2-156 |

4 | 21 | 11 | 10 | 2.3 | |||||||||||||

| MPD 5.5-195 |

5 | 25 | 12 | 13 | 3.4 | |||||||||||||

| Model | bΦ (mm) |

L (mm) |

F (mm) |

H (mm) |

DΦ (mm) |

EΦ (mm) |

|||||||||||||||

| FRD 1.25- 156 |

4 | 24 | 13 | 11 | 1.7 | 6 | |||||||||||||||

| FRD 2-156 |

4 | 24 | 13 | 11 | 2.3 | 6 | |||||||||||||||

| FRD 5.5-156 |

5 | 25 | 13 | 12 | 2.3 | 7 | |||||||||||||||

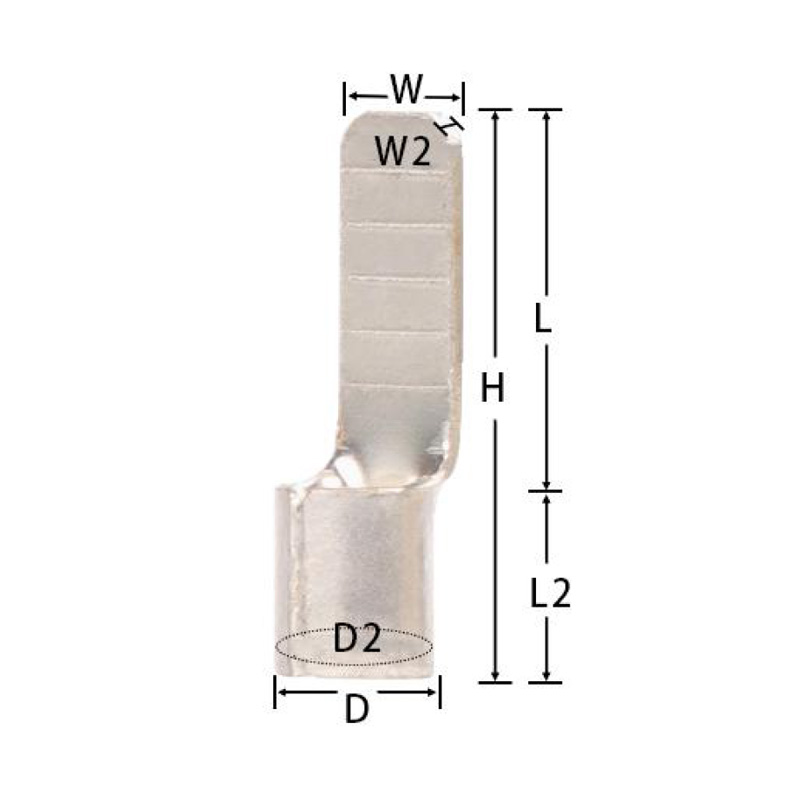

Female Spade Quick Splice CrimpTerminals

| Model | L (mm) |

W (mm) |

W2 (mm) |

Thickness(mm) | Wiring range(m ㎡) | |||||||||||||||||||||||||||||||||||

| 2.8 | 16 | 4 | 2.8 | 0.3 | 0.25~0.75 | |||||||||||||||||||||||||||||||||||

| 4.8 | 14.4 | 5.6 | 4.8 | 0.3 | 0.3~0.75 | |||||||||||||||||||||||||||||||||||

| 6.3 | 17.2 | 7.2 | 6.3 | 0.35 | 0.75~ 1.5 | |||||||||||||||||||||||||||||||||||

| 7.8 | 25 | 8.7 | 7.8 | 0.35 | 1.5~2.5 | |||||||||||||||||||||||||||||||||||

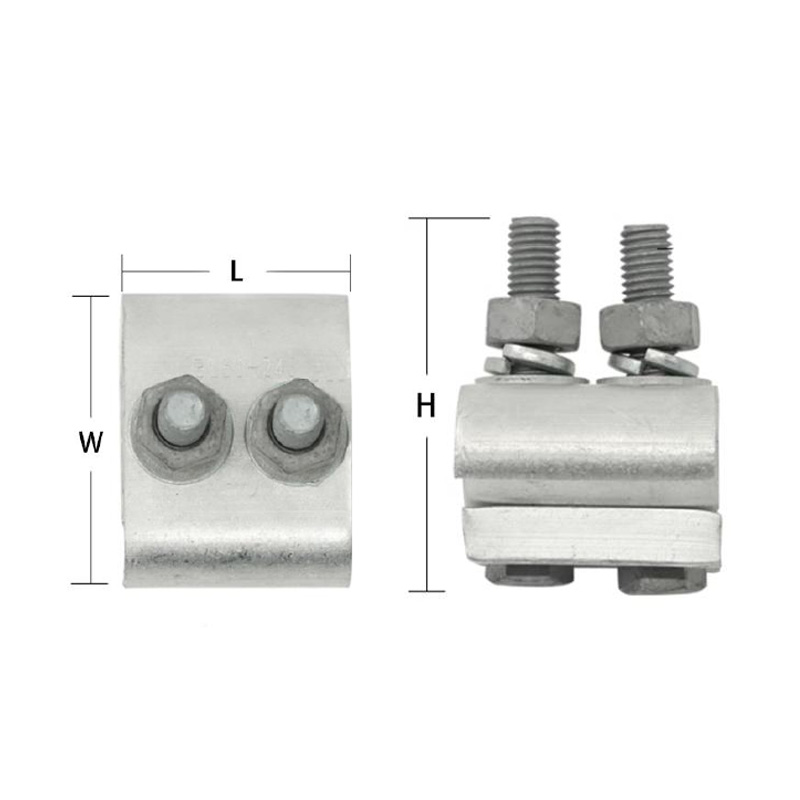

PG Industrial Connectors

| Model | Material | Wiring range ( m㎡ ) |

L , W , H ( mm ) |

|||||||||||||||||||||||||

| JBL10-70 | Aluminium | 10-70 | 40x36x45.5 | |||||||||||||||||||||||||

| JBL16-120 | Aluminium | 16-120 | 45.5x45x55.5 | |||||||||||||||||||||||||

| JBL50-240 | Aluminium | 50-240 | 45.5x61.5x60.5 | |||||||||||||||||||||||||

| JBTL10-70 | Copper Aluminium |

10-70 | 40x36x50.5 | |||||||||||||||||||||||||

| JBTL16-120 | Copper Aluminium |

16-120 | 47x45x56.5 | |||||||||||||||||||||||||

| JBTL50-240 | Copper Aluminium |

50-240 | 47x60x60.5 | |||||||||||||||||||||||||

| JBT10-70 | Copper | 10-70 | 40.3x34x45 | |||||||||||||||||||||||||

| JBT16-120 | Copper | 16-120 | 45.5x46.3x56.2 | |||||||||||||||||||||||||

| JBT50-240 | Copper | 50-240 | 47x58x60.5 | |||||||||||||||||||||||||

C45 Connector

| Model | L (mm) |

L2 (mm) |

H (mm) |

W (mm) |

W2 (mm) |

D (mm) |

D2 (mm) |

Material | Wirin g range (m㎡) |

||||||||||||||||||||||

| C45-1.5 | 12.6 | 5 | 17.6 | 4.6 | 0.5 | 3.4 | 2.2 | Silver Copper |

1.5 | ||||||||||||||||||||||

| C45-2.5 | 13.1 | 5.1 | 18.2 | 4.6 | 0.6 | 4 | 2.6 | Silver Copper |

2.5 | ||||||||||||||||||||||

| C45-4 | 12.9 | 5.8 | 18.7 | 4.7 | 0.6 | 4.9 | 3.4 | Silver Copper |

4 | ||||||||||||||||||||||

| C45-6 | 13.8 | 7.2 | 21 | 5.8 | 0.7 | 6 | 4.1 | Silver Copper |

6 | ||||||||||||||||||||||

| C45-10 | 14.1 | 8.4 | 22.5 | 5.9 | 0.9 | 7.3 | 5.4 | Silver Copper |

10 | ||||||||||||||||||||||

| C45-16 | 15.7 | 10.5 | 26.2 | 6.7 | 1.2 | 9.7 | 7 | Silver Copper |

16 | ||||||||||||||||||||||

| C45-25 | 15.8 | 12.2 | 28 | 7 | 1.4 | 11.8 | 8.7 | Silver Copper |

25 | ||||||||||||||||||||||

| C45-35 | 16.6 | 13.4 | 30 | 7 | 1.4 | 12.6 | 9.5 | Silver Copper |

35 | ||||||||||||||||||||||

| C45-50 | 17 | 14.2 | 31.2 | 7 | 1.5 | 14.7 | 11.5 | Silver Copper |

50 | ||||||||||||||||||||||

| C45-70 | 23.5 | 19 | 42.5 | 7.3 | 1.8 | 17.5 | 13.5 | Silver Copper |

70 | ||||||||||||||||||||||

| DTD-10 | 15.3 | 19 | 34.3 | 5.3 | 4.2 | 7.4 | 5 | Tinned Copper |

10 | ||||||||||||||||||||||

| DTD-16 | 15 | 20 | 35 | 6.45 | 4.95 | 8.5 | 6 | Tinned Copper |

16 | ||||||||||||||||||||||

| DTD-25 | 15 | 20.5 | 35.5 | 6.9 | 4.5 | 9.8 | 7 | Tinned Copper |

25 | ||||||||||||||||||||||

| DTD-35 | 14.5 | 19.3 | 33.8 | 6.8 | 4.6 | 9.8 | 7.7 | Tinned Copper |

35 | ||||||||||||||||||||||

High Frequency Ceramic Junction Box

Product Name: High frequency ceramic junction box

Ampacity: 5-100A

Insulation voltage: 250V

Input: 1.5~16mm

Output: 1.5~16mm

Suitable temperature: -40~800°C

PE Heat Shrink Tubing Heat Shrinkable Sleeves

| Color | Size Φ (mm) | |||||||||||||||||||||||||||||||||||||||||

| Black | 2 | 4 | 5 | 10 | ||||||||||||||||||||||||||||||||||||||

| Yellow | 1.5 | 6 | ||||||||||||||||||||||||||||||||||||||||

| Green | 3 | 10 | ||||||||||||||||||||||||||||||||||||||||

| Blue | 2 | 10 | ||||||||||||||||||||||||||||||||||||||||

| Red | 4 | 8 | ||||||||||||||||||||||||||||||||||||||||

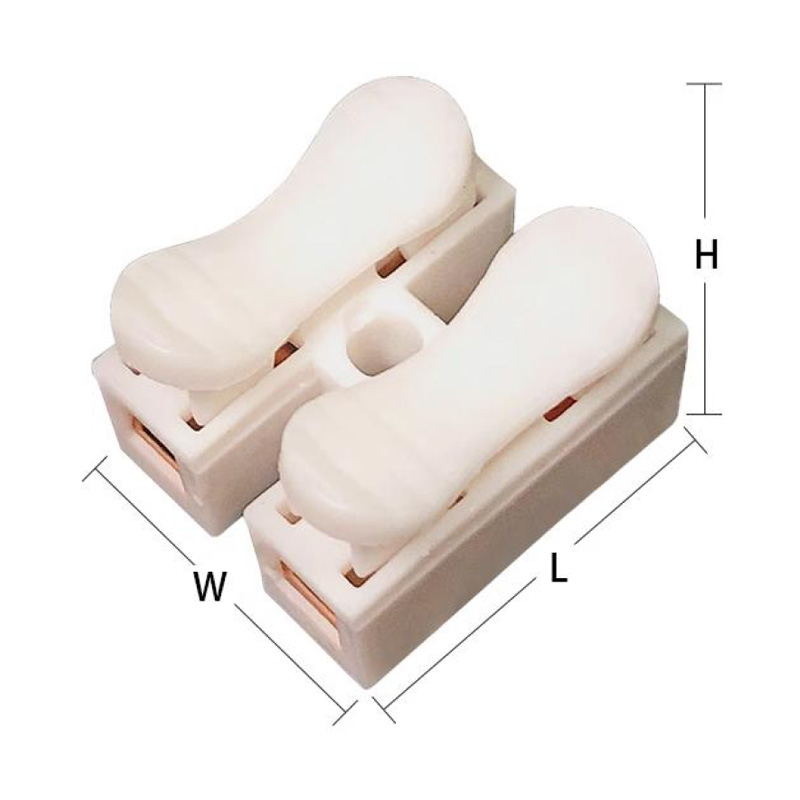

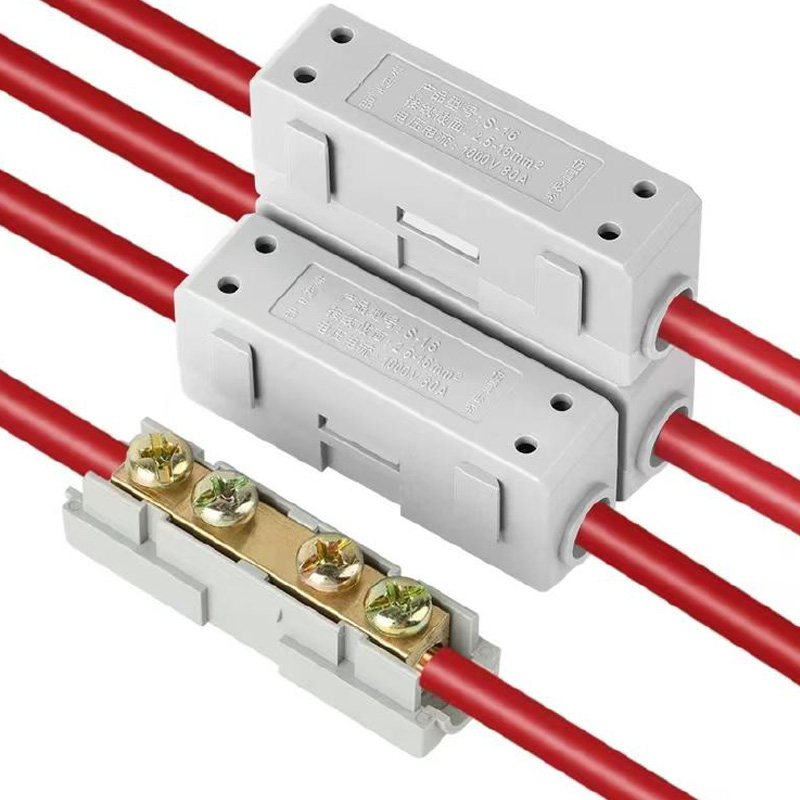

Wire Connertor

Product Name: Wire Connector

Shell Material: PA

Guide Material: High Quality

ImpulseVoltage: 4KV

Product Use: Used for connecting parts ofelectric wires such as motor, electrical control, supply, household appliances, lighting, machinery, etc.

| Item | L (mm) |

W (mm) |

H (mm) |

Rated Current |

Rated Voltage |

Applicable Wire | ||||||||||||||||||||||||||||||||||

| Wire Connector | 20 | 17.5 | 13.5 | 10.0 | 250v | hard wire0.5~1.5mm 2 flesible wire 0.5~2.5m㎡ |

||||||||||||||||||||||||||||||||||

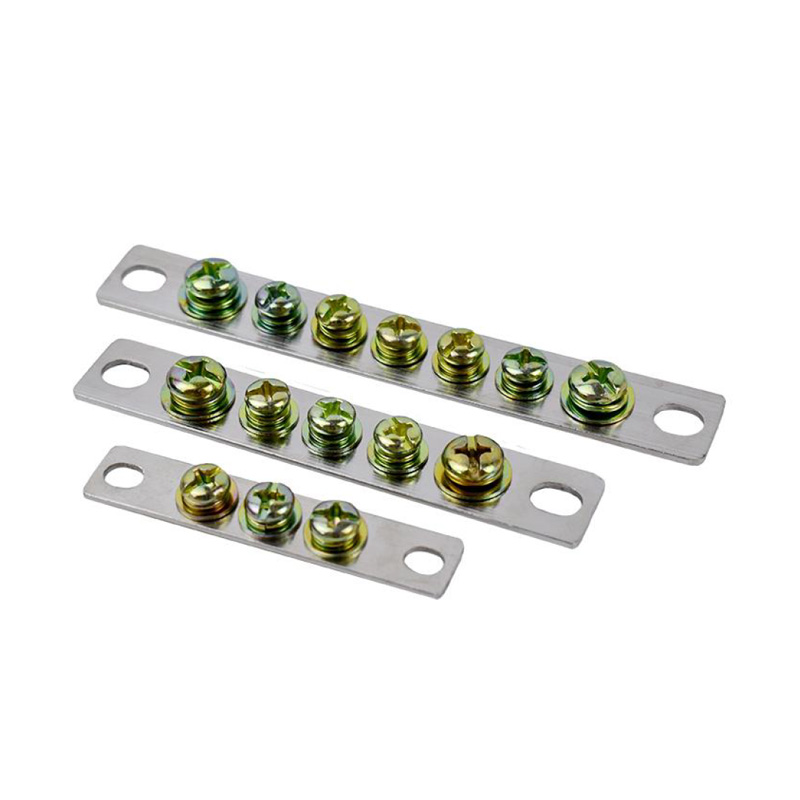

Zero Grounding Bar Wire

| PRODUCT MODEL | SCREW SIZE (mm) |

LENGTH (mm) |

BREADTH (mm) |

THICKNESS (mm) |

PITCH OF HOLES (mm) |

| 3-2*15 | M8 | 82 | 15 | 1.5 | 68 |

| 52*15 | M8/M5 | 99 | 15 | 1.5 | 86 |

| 5-2*20 | M8/M6 | 106 | 20 | 1.8 | 92 |

| 5-2.5*20 | M8 | 125 | 20 | 2.1 | 109 |

| 5-2.5*25 | M8 | 129 | 25 | 2.2 | 111 |

| 5-3*25 | M8 | 124 | 25 | 2.6 | 107 |

| 5-3*30 | M8 | 130 | 30 | 2.9 | 113 |

| 7-2*15 | M8/M5 | 128 | 15 | 1.5 | 114 |

| 7-2*20 | M8/M6 | 132 | 20 | 1.85 | 118 |

| 7-2*25 | M8 | 163 | 25 | 1.9 | 145 |

| 7-2.5*20 | M8 | 160 | 20 | 2 | 145 |

| 7-2.5*25 | M8 | 163 | 25 | 2.3 | 147 |

| 7-3*15 | M8/M6 | 131 | 15 | 2.5 | 115 |

| 7-3*25 | M8 | 158 | 25 | 2.6 | 141 |

| 7-3*30 | M8 | 165 | 30 | 2.9 | 147 |

| 10-2*15 | M8/M5 | 156 | 15 | 1.5 | 143 |

| 10-2*20 | M8/M6 | 172 | 20 | 1.8 | 156 |

| 10-2.5*20 | M8 | 214 | 20 | 2.1 | 198 |

| 10-2.5*25 | M8 | 213 | 25 | 2.3 | 197 |

| 10-3*15 | M8/M6 | 172 | 15 | 2.5 | 156 |

| 10-3*25 | M8 | 209 | 25 | 2.6 | 192 |

| 10-3*30 | M8 | 220 | 30 | 2.9 | 198 |

Bar Wire

| Item | Screw Hole | Length (mm) |

Breadth (mm) |

High | |||||||||||||||||||||||||||

| 4-5.5*7.5 | M4 | 26.36 | 5.5 | 7.5 | |||||||||||||||||||||||||||

| 6-5.5*7.5 | M4 | 39 | 5.5 | 7.5 | |||||||||||||||||||||||||||

| 8-5.5*7.5 | M4 | 51.57 | 5.5 | 7.5 | |||||||||||||||||||||||||||

| 10-5.5*7.5 | M4 | 63.17 | 5.5 | 7.5 | |||||||||||||||||||||||||||

| 4-6*10 | M4 | 29.85 | 6 | 10 | |||||||||||||||||||||||||||

| 6-6*10 | M4 | 45.5 | 6 | 10 | |||||||||||||||||||||||||||

| 8-6*10 | M4 | 59.7 | 6 | 10 | |||||||||||||||||||||||||||

| 10-6*10 | M4 | 73.5 | 6 | 10 | |||||||||||||||||||||||||||

| 6-7*11 | M5 | 51.7 | 7 | 11 | |||||||||||||||||||||||||||

| 8-7*11 | M5 | 67.7 | 7 | 11 | |||||||||||||||||||||||||||

| 10-7*11 | M5 | 82.9 | 7 | 11 | |||||||||||||||||||||||||||

| 6-8*13 | M5 | 58.2 | 8 | 13 | |||||||||||||||||||||||||||

| 8-8*13 | M5 | 74.4 | 8 | 13 | |||||||||||||||||||||||||||

| 10-8*13 | M5 | 91.57 | 8 | 13 | |||||||||||||||||||||||||||

| Item | Rated Voltage |

Wiring Range (m㎡) |

Length (mm) |

Breadth (mm) |

High (mm) |

||||||||||||||||||||||||||||||

| I-16 | 80A/1000V | 2.5-16 | 46 | 13 | 23 | ||||||||||||||||||||||||||||||

| I-25 | 100A1000V | 6-25 | 50 | 13 | 26 | ||||||||||||||||||||||||||||||

| I-35 | 120A-1000V | 10-35 | 72 | 18 | 32 | ||||||||||||||||||||||||||||||

| I-50 | 150A-1000V | 25-50 | 72 | 20 | 34 | ||||||||||||||||||||||||||||||

Search

Categories

-

Energy Measuring Terminal Block(314)

- Energy Measuring Joint Terminal Block(16)

- Polycarbonate Energy Measuring Terminal Block(24)

- Standard Wiring Energy Measuring Terminal Block(4)

- Transparent Shell Energy Measuring Terminal Block(6)

- Multifunctional Test Energy Measuring Terminal Block(10)

- Intelligent Safety Energy Measuring Terminal Block(6)

- Single-Phase Multi-Circuit Output Terminal Block(12)

- Self-Elevating Metering Box Terminal Block(7)

- One Household One-Meter Meter Box Dedicated Terminal Block(56)

- Three-Phase Metering Box Dedicated Terminal Block(24)

- Repeatable Grounding Line Terminal Block(20)

- Terminal Block for One-Inlet Multi-Outlet Metering Box(15)

- Closed Terminal Block(11)

- Heavy Current Terminal Block(48)

- Self-Boosting Terminal Block(5)

- Intelligent Self-Locking Terminal Block(3)

- Tool-Free Crimping Type Terminal Block(5)

- Wide Range of Wire Diameters Terminal Block(5)

- Combined Type Energy Measuring Terminal Block(37)

-

Switch Terminal Block(55)

- Pin-Type Incoming Line Switch Terminal Block(4)

- Multi-Way Connection Switch Terminal Block(4)

- Plug-pin Switch Terminal Block(7)

- Combined Type Switch Terminal Block(7)

- High Contact Cross Section Switch Terminal Block(7)

- Wide Range Switch Terminal Block(11)

- One Way in Switch Terminal Block(12)

- Equipped with Circuit Breaker Switch Terminal(3)

-

Heavy-current Terminal Block(631)

- Modular Building Block Terminal Block(156)

- Spherical Non-Destructive Crimp Terminal(120)

- Dual-Mode Connection Electrical Terminal(90)

- Anti-Electricity-Theft Terminal Block(74)

- Convenient Connection Terminal Block(12)

- High-Contact Section Terminal Block(12)

- Wide Range of Wire Diameters Neutral Line Terminal(9)

- Heavy-Current Neutral Line Terminal(9)

- Upper and Lower Rows of Neutral Terminal(2)

- Independent Neutral Line Terminal(7)

- Nose-Type Neutral Line Terminal(7)

- Rail Type Neutral Line Terminal(9)

- Fixed Neutral Line Terminal(12)

- Double Rail Assembly Electrical Terminal(19)

- Blue Jack-Up Terminal(6)

- Black Base Copper Bar Terminal(5)

- Compact Terminal Block(16)

- Precision Terminal Block(23)

- U-Shaped Harpoon Terminal(2)

- Grounding Metering Box Terminal Block(12)

- High-Performance Terminal Block(19)

- Multifunctional Terminal Block(10)

- Din Rail Terminal Block(76)

- Watt-hour Meter Connector(49)

-

Energy Meter Accessories(116)

-

-

Secure connections are essential for reliable electrical distribution, especially when installing a High-performance Terminal Bloc...

READ MORE -

For engineers and panel builders striving for both efficiency and reliability, wiring errors remain a persistent headache — even w...

READ MORE -

In modern electrical systems, a High-performance Terminal Block plays a critical role in ensuring secure and reliable connections ...

READ MORE -

When building or maintaining electrical systems, one frequently overlooked but critical factor is matching the conductor size to t...

READ MORE -

Effective electrical connections depend on more than simply matching cable sizes. Whether you’re securing a power conductor with a...

READ MORE

What Are The Functions Of Energy Meter Accessories?

Energy meter accessories serve several critical functions that contribute to the overall performance and safety of energy measurement systems.

- 1. Electrical Connection and Safety: Accessories like cable lugs and wire connectors ensure a secure connection between the energy meter and the electrical circuit. They prevent loose connections that can electrical fires or inaccurate readings.

- 2. Enhanced Accuracy: Properly functioning accessories help maintain the accuracy of energy meter readings by energy loss and ensuring stable current flow.

- 3. Durability and Longevity: High-quality accessories are designed to withstand the rigors of electrical stress, environmental conditions, and mechanical wear, prolonging the life of the energy meter.

- 4. Ease of Maintenance: Accessories that are easy to install and remove facilitate regular maintenance and inspection, which is crucial for the upkeep of energy meters.

- 5. Compliance with Standards: Energy meter accessories are often designed to comply with international safety and performance standards, ensuring that they meet the requirements of regulatory bodies.

What Are The Types Of Cable Lugs?

Cable lugs are connectors used to join cables and wires to termination points. They come in various types, each designed for specific applications and conditions.

- 1. Solder Lugs: These lugs require soldering to create a secure connection. They are suitable for applications where a permanent and highly reliable connection is needed.

- 2. Insulation Displacement Lugs (IDL): These lugs are designed to pierce and displace the insulation of a wire, creating a secure connection without the need for stripping the wire. They are popular for their ease of use and time-saving properties.

- 3. Crimp Lugs: Crimp lugs are connected to wires using a crimping tool that compresses the lug around the wire, ensuring a tight and secure connection. They are widely used in various electrical installations due to their versatility.

- 4. Split Bolt Lugs: These lugs are opened and closed around a cable or wire using a bolt. They are easy to install and are commonly used in situations where the connection may need to be frequently disconnected.

- 5. Compression Lugs: Similar to crimp lugs, compression lugs are used with a compression tool to secure the connection. They are known for their high conductivity and resistance to corrosion.

- 6. Push-On Lugs: These lugs are simply pushed onto the wire, making them quick and easy to install. However, they may not provide the same level of security and reliability as other types of lugs.

How to Choose the Right Wire Connector

Selecting the appropriate wire connector is a critical decision that affects the performance and safety of an electrical system. Here are some factors to consider when choosing a wire connector:

- 1. Material and Construction: The material of the connector (copper, aluminum, or a combination) and its construction (solid or stranded wire) should be considered based on the application's requirements.

- 2. Wire Gauge: The size of the wire (gauge) must match the connector's specifications to ensure a proper fit and avoid overheating or electrical failure.

- 3. Environment: The environment in which the connector will be used is crucial. Outdoor applications may require connectors with UV resistance and weatherproofing, while indoor applications may prioritize ease of installation.

- 4. Load Capacity: The connector must be able to handle the electrical load it will be subjected to without overheating or failing.

- 5. Safety Standards: Ensure that the connector complies with safety standards such as UL, CSA, or IEEE, which are designed to protect against electrical hazards.

- 6. Ease of Installation: Consider the ease of installation, especially in tight spaces or where frequent disconnections are required.

- 7. Cost-Effectiveness: While cost should not be the only factor, it is essential to find a balance between quality and affordability.

English

English Español

Español عربى

عربى