Integrating wired connectivity into the era of automation and digital networking involves more than just traditional hardware. A H...

READ MORETransparent Shell Energy Measuring Terminal Block Manufacturer

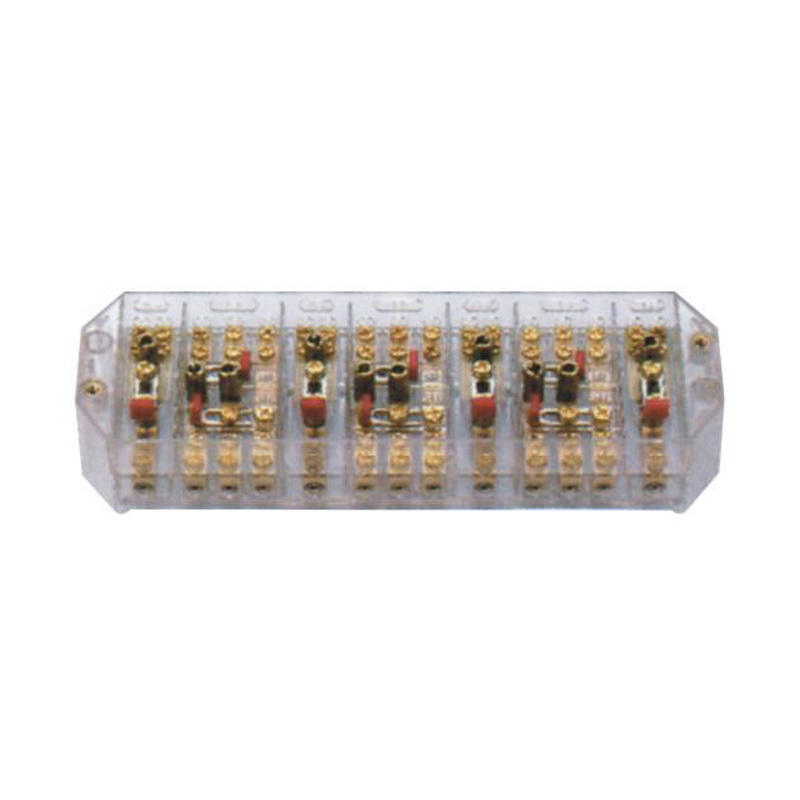

Transparent Shell Energy Measuring Terminal Blocks are professionally used for energy measurement and monitoring in electrical systems, with the added advantage of a transparent shell design that enhances visual inspection and ease of maintenance. These terminal blocks are specifically designed to provide accurate energy measurement while allowing users to easily observe the internal connections and components, ensuring reliable and safe operation.

These terminal blocks feature a secure and stable connection design, without the need for excessive wiring or additional conductors. The transparent shell not only provides clear visibility of the internal structure but also ensures that the terminal block remains robust and protected against environmental factors.

Transparent Shell Energy Measuring Terminal Blocks are currently a novel product offering a convenient and highly reliable solution for energy measurement in electrical systems. They simplify the inspection and maintenance processes, enhance system reliability, and provide accurate energy data while ensuring a safe and secure connection.

One of the primary selling points of these terminal blocks is their transparent design. This feature allows for direct visual inspection of connections without the need for additional tools or disassembly. This transparency is not only convenient but also essential for quick diagnostics and troubleshooting, reducing downtime and maintenance costs. It also enables users to monitor the status of connections in real-time, ensuring that any issues are identified and addressed promptly.

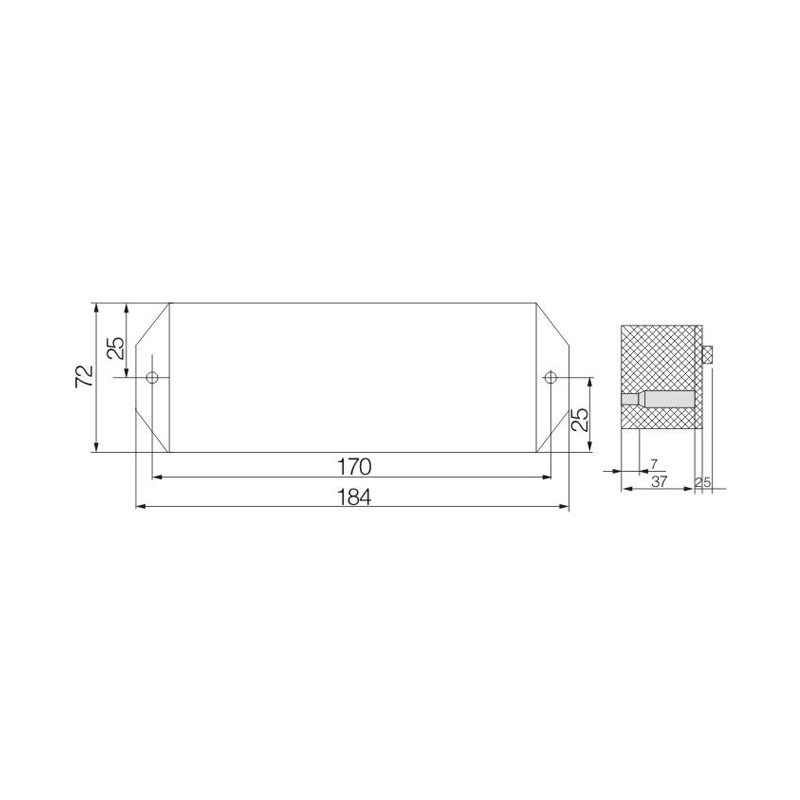

FJ6/HD3L Energy Measuring Terminal Block

Model:FJ6/HD3L

Product name: Three-phase three-wire energy measuring terminal block

Order number: OrderNo.150045

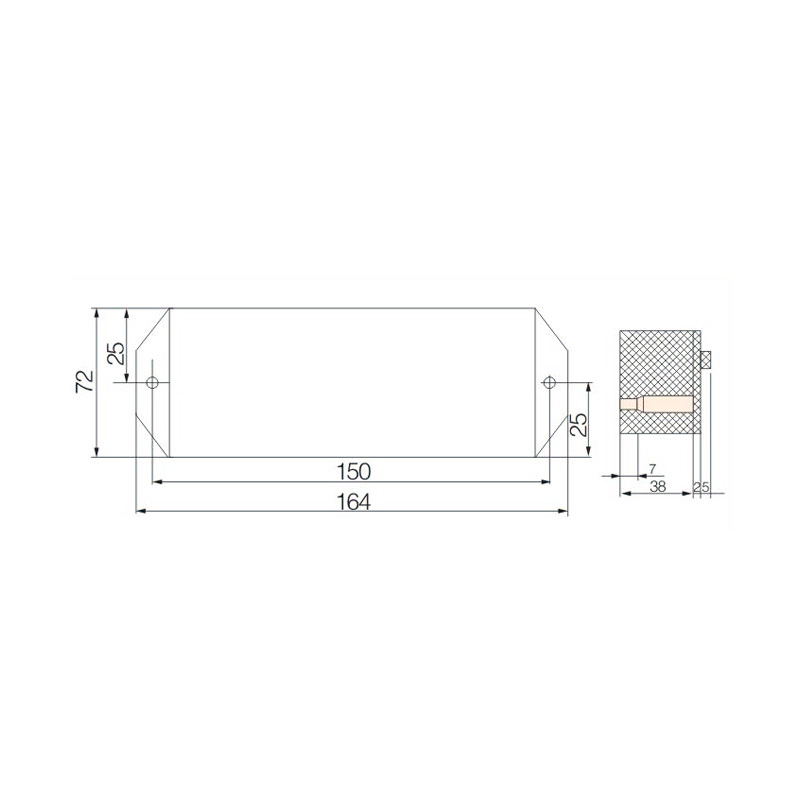

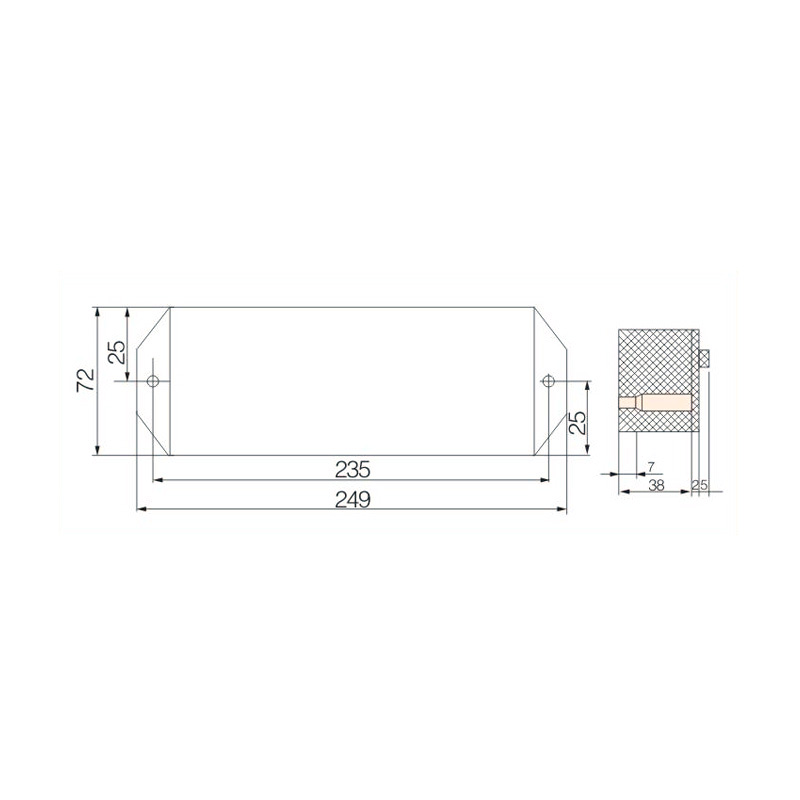

FJ6/HD4L Energy Measuring Terminal Block

Model:FJ6/HD4L

Product name: Three-phase four-wire energy measuring terminal block

Order number: OrderNo.150046

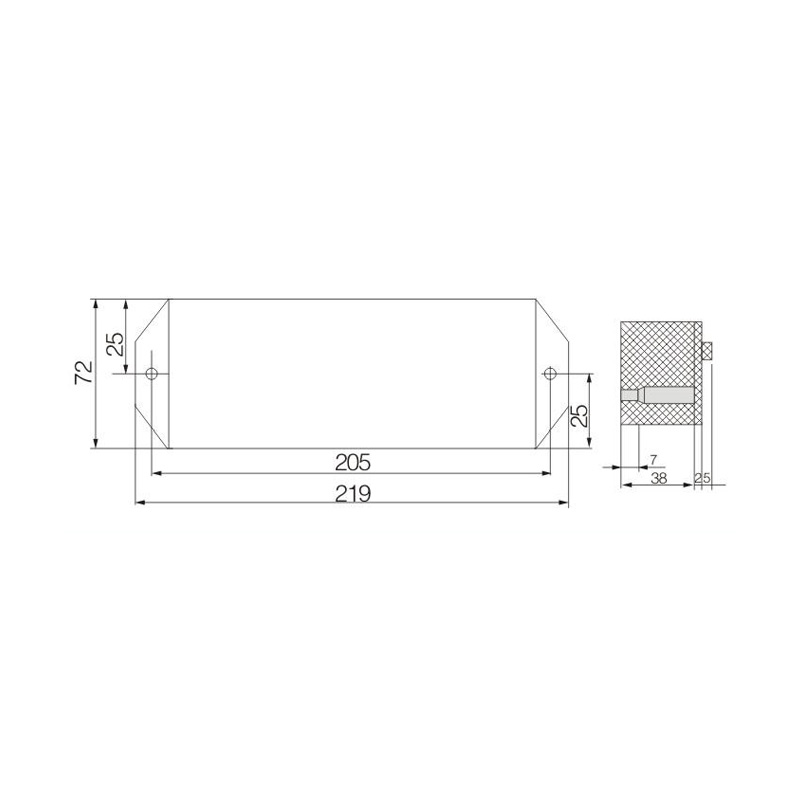

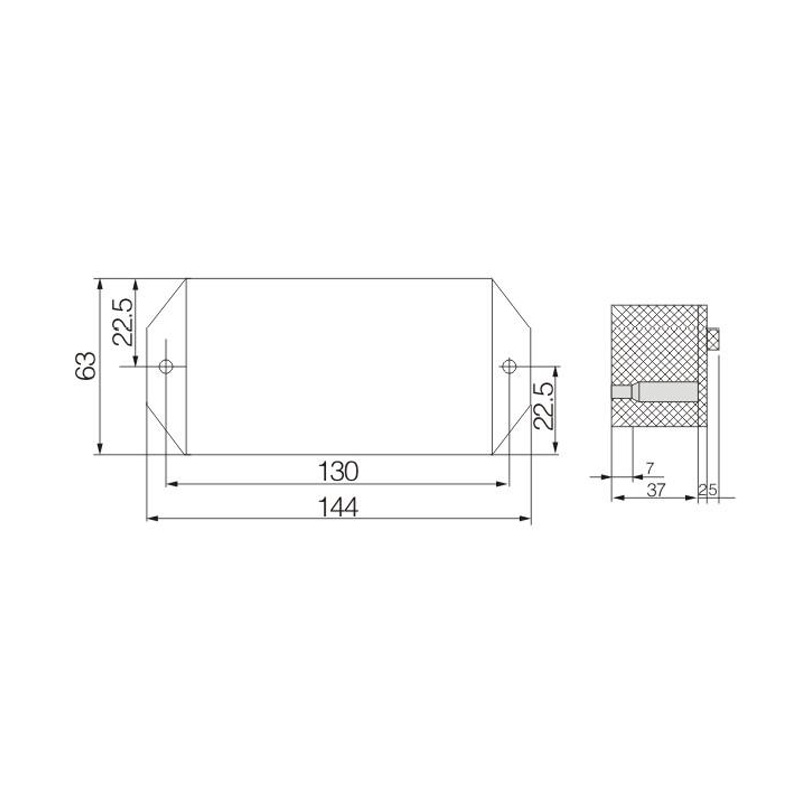

DKPJ1 Energy Measuring Terminal Block

Model:DKPJ1 Type (transparent,bulletproof)

Product name: Three-phase four-wire power contoller terminal block

Order number: OrderNo.150047

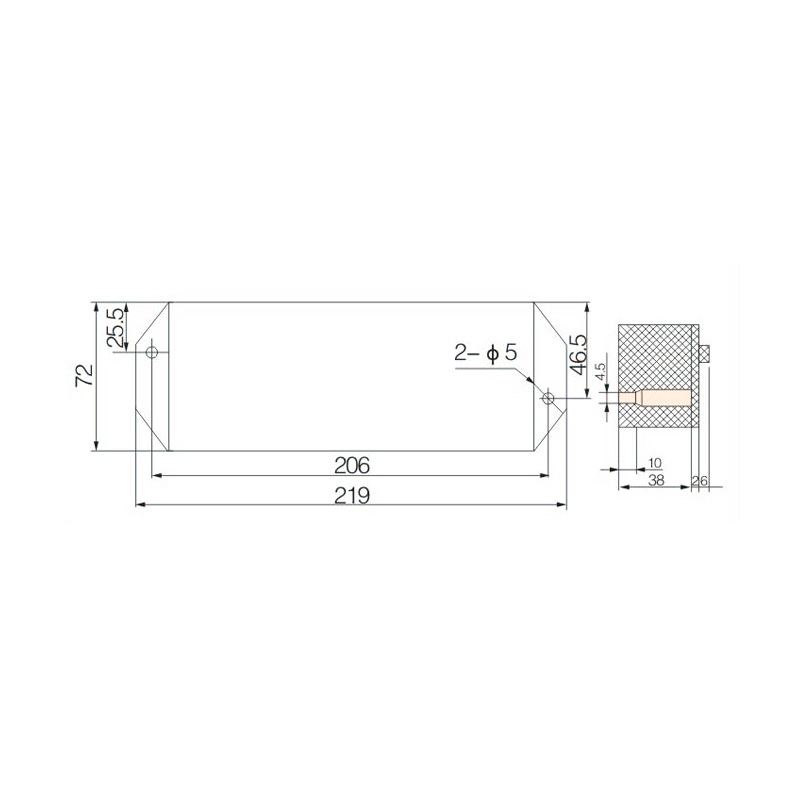

FJ6/PJ2L Energy Measuring Terminal Block

Model:FJ6/PJ2L

Product name: Three-phase three-wire energy measuring terminal block

Order number: OrderNo.150048

FJ6/PJ1L Energy Measuring Terminal Block

Model:FJ6/PJ1L

Product name: Three-phase four-wire energy measuring terminal block

Order number: OrderNo.150049

FJ6/HDL Energy Measuring Terminal Block

Model:FJ6/HDL

Product name: Energy measuring terminal block

Order number: OrderNo.150050

Search

Categories

-

Energy Measuring Terminal Block(314)

- Energy Measuring Joint Terminal Block(16)

- Polycarbonate Energy Measuring Terminal Block(24)

- Standard Wiring Energy Measuring Terminal Block(4)

- Transparent Shell Energy Measuring Terminal Block(6)

- Multifunctional Test Energy Measuring Terminal Block(10)

- Intelligent Safety Energy Measuring Terminal Block(6)

- Single-Phase Multi-Circuit Output Terminal Block(12)

- Self-Elevating Metering Box Terminal Block(7)

- One Household One-Meter Meter Box Dedicated Terminal Block(56)

- Three-Phase Metering Box Dedicated Terminal Block(24)

- Repeatable Grounding Line Terminal Block(20)

- Terminal Block for One-Inlet Multi-Outlet Metering Box(15)

- Closed Terminal Block(11)

- Heavy Current Terminal Block(48)

- Self-Boosting Terminal Block(5)

- Intelligent Self-Locking Terminal Block(3)

- Tool-Free Crimping Type Terminal Block(5)

- Wide Range of Wire Diameters Terminal Block(5)

- Combined Type Energy Measuring Terminal Block(37)

-

Switch Terminal Block(55)

- Pin-Type Incoming Line Switch Terminal Block(4)

- Multi-Way Connection Switch Terminal Block(4)

- Plug-pin Switch Terminal Block(7)

- Combined Type Switch Terminal Block(7)

- High Contact Cross Section Switch Terminal Block(7)

- Wide Range Switch Terminal Block(11)

- One Way in Switch Terminal Block(12)

- Equipped with Circuit Breaker Switch Terminal(3)

-

Heavy-current Terminal Block(631)

- Modular Building Block Terminal Block(156)

- Spherical Non-Destructive Crimp Terminal(120)

- Dual-Mode Connection Electrical Terminal(90)

- Anti-Electricity-Theft Terminal Block(74)

- Convenient Connection Terminal Block(12)

- High-Contact Section Terminal Block(12)

- Wide Range of Wire Diameters Neutral Line Terminal(9)

- Heavy-Current Neutral Line Terminal(9)

- Upper and Lower Rows of Neutral Terminal(2)

- Independent Neutral Line Terminal(7)

- Nose-Type Neutral Line Terminal(7)

- Rail Type Neutral Line Terminal(9)

- Fixed Neutral Line Terminal(12)

- Double Rail Assembly Electrical Terminal(19)

- Blue Jack-Up Terminal(6)

- Black Base Copper Bar Terminal(5)

- Compact Terminal Block(16)

- Precision Terminal Block(23)

- U-Shaped Harpoon Terminal(2)

- Grounding Metering Box Terminal Block(12)

- High-Performance Terminal Block(19)

- Multifunctional Terminal Block(10)

- Din Rail Terminal Block(76)

- Watt-hour Meter Connector(49)

-

Energy Meter Accessories(116)

-

-

Secure connections are essential for reliable electrical distribution, especially when installing a High-performance Terminal Bloc...

READ MORE -

For engineers and panel builders striving for both efficiency and reliability, wiring errors remain a persistent headache — even w...

READ MORE -

In modern electrical systems, a High-performance Terminal Block plays a critical role in ensuring secure and reliable connections ...

READ MORE -

When building or maintaining electrical systems, one frequently overlooked but critical factor is matching the conductor size to t...

READ MORE -

Effective electrical connections depend on more than simply matching cable sizes. Whether you’re securing a power conductor with a...

READ MORE

Where Are The Innovations In Electrical Terminal Blocks?

The evolution of electrical components continues to focus on enhancing safety, reliability, and ease of use. Among these developments, the transparent shell energy measuring terminal block and the waterproof terminal strip block represent significant advancements. These components address critical needs in electrical installations, from providing visual verification to ensuring durability in challenging environments. This essay will explore the importance of the transparent shell design and break down the key features of the waterproof terminal block into three core aspects.

Where Is The Significance Of The Transparent Shell Energy Measuring Terminal Block?

The transparent shell energy measuring terminal block offers a practical and impactful departure from traditional opaque designs. Its primary significance lies in the introduction of visibility, which directly enhances safety and operational efficiency. In standard installations, terminal blocks are enclosed within cabinets or panels, making it difficult to inspect the status of connections without disassembly. The transparent housing eliminates this barrier, allowing for immediate visual inspection. This enables technicians to quickly verify that wires are properly seated, clamping mechanisms are secure, and there are no visible signs of distress, such as overheating, corrosion, or arcing.

This feature is particularly valuable in energy measurement applications, where connection integrity is paramount for accurate data collection. A loose or faulty connection can increased resistance, generating heat and potentially causing a fire hazard. It can also result in inaccurate energy readings, financial discrepancies or incorrect system performance data. The ability to perform a rapid, non-invasive inspection reduces downtime and allows for proactive maintenance, preventing small issues from escalating into major failures.

Furthermore, the transparent design aids in error prevention during installation and wiring. In complex panels with multiple circuits, the ability to see the internal layout helps ensure that wires are connected to the correct terminals, reducing the risk of miswiring. This combination of enhanced safety, improved maintenance efficiency, and error reduction makes the transparent shell terminal block a valuable component in modern electrical systems.

Waterproof Terminal Strip Block: Do You Know?

1. Environmental Sealing and Durability

The fundamental purpose of a waterproof terminal strip block is to provide a reliable connection in environments exposed to moisture, dust, and other contaminants. This is achieved through meticulous design features such as integrated rubber gaskets, sealed entry points for cables, and a housing made from corrosion-resistant materials like high-grade thermoplastics or stainless steel. These elements work together to create an ingress protection (IP) rating, often IP67 or higher, signifying its ability to withstand temporary immersion and protect against dust. This durability ensures the terminal block's longevity and consistent performance in outdoor applications, industrial settings, or humid conditions where standard blocks would fail.

2. Electrical Safety and Insulation

In wet or damp conditions, the risk of electrical short circuits, leakage currents, and corrosion increases dramatically. The waterproof terminal block is engineered to mitigate these risks. The sealed enclosure prevents water from bridging the gaps between terminals, effectively maintaining proper insulation resistance. The internal design often includes deep barriers between poles and ample creepage and clearance distances, which are essential for preventing arc-over in humid air. This robust insulation is critical for protecting both the electrical system and personnel from potential electrical hazards, making it a necessary safety component for any exposed installation.

3. Mechanical Protection and Connection Integrity

Beyond keeping out water, the waterproof enclosure offers significant mechanical protection. It shields the delicate electrical connections from physical impact, vibration, and the presence of corrosive agents like salt spray or chemicals. The internal clamping mechanisms are typically designed to be robust, maintaining a strong, gas-tight connection on the wires even under stress. This ensures a stable, low-resistance connection that is vital for the accurate transmission of power or signals. The housing also often includes features like mounting lugs and clear markings for easy and secure installation, contributing to the overall reliability and longevity of the connection point.

English

English Español

Español عربى

عربى