Integrating wired connectivity into the era of automation and digital networking involves more than just traditional hardware. A H...

READ MOREThree-Phase Metering Box Dedicated Terminal Block Manufacturer

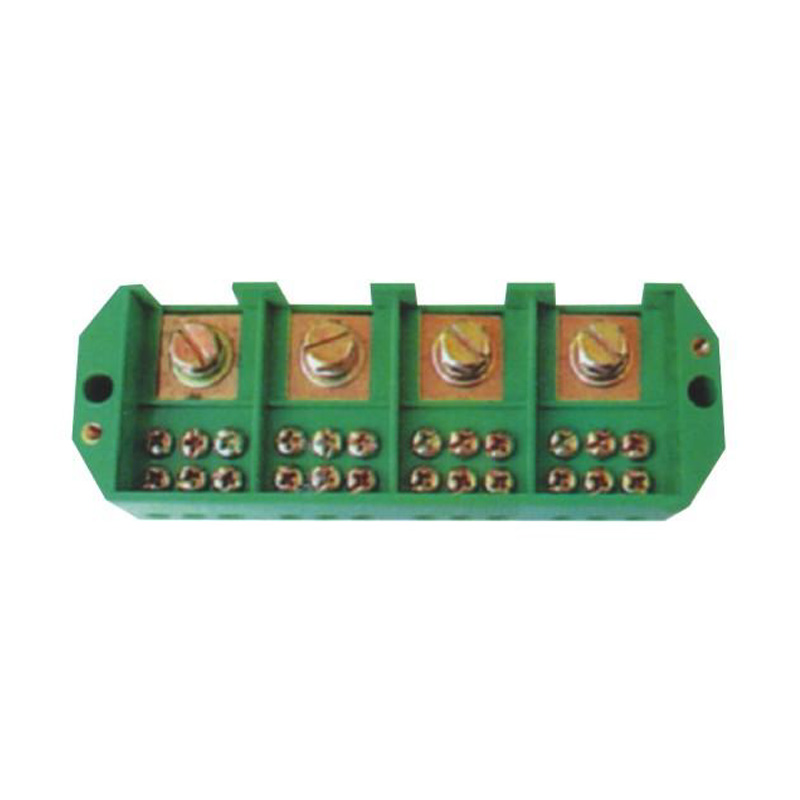

With the increase in the number of power users and the centralized installation and management of metrology devices, our company has developed a Three-Phase Metering Box Dedicated Terminal Block with changing market needs. It is a new generation of multi-functional products that our company has launched on the market.

This product has been inspected by the power related departments and complies with the national standards and safe electricity use requirements. It is promoted and used by more and more electric pipe units.

The product is small in size, has a large current carrying capacity, has a large number of installed households, has high pressure resistance, compact structure, convenient installation, beautiful appearance, and has a variety of high-quality characteristics such as flame retardancy, non-absorbing, moisture resistance, good insulation performance, and anti-aging. It adopts a transparent cover plate with good perspective; the outgoing line is closed, safe and reliable.

The Three-Phase Metering Box Dedicated Terminal Block for Three-Phase Metering Boxes is constructed from high-quality materials that ensure durability and longevity. The use of outstanding materials not only extends the product's lifespan but also guarantees that it can withstand the rigors of daily use in harsh environments, including high temperatures, humidity, and corrosion.

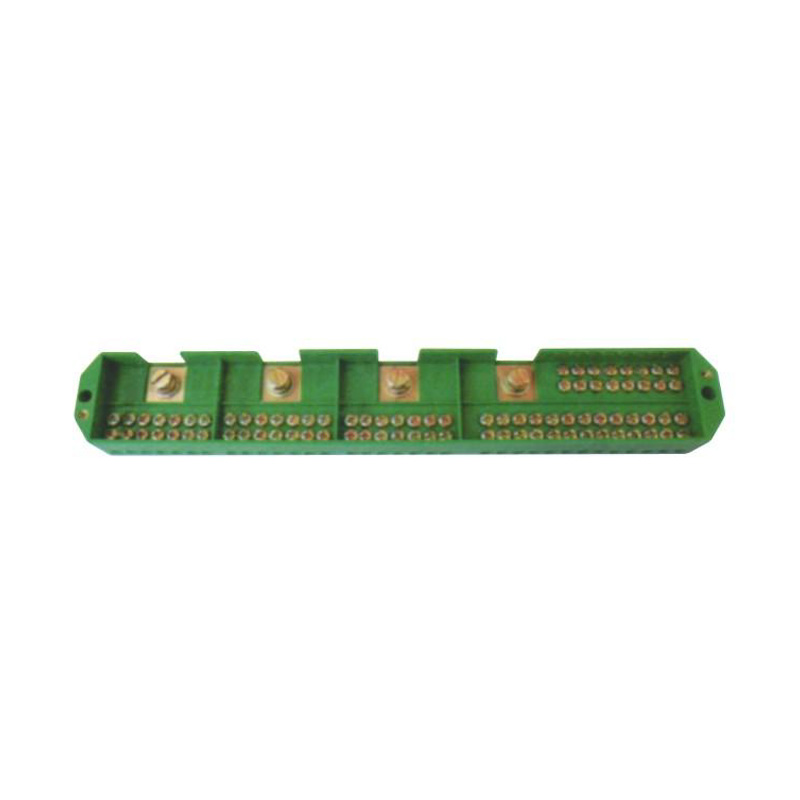

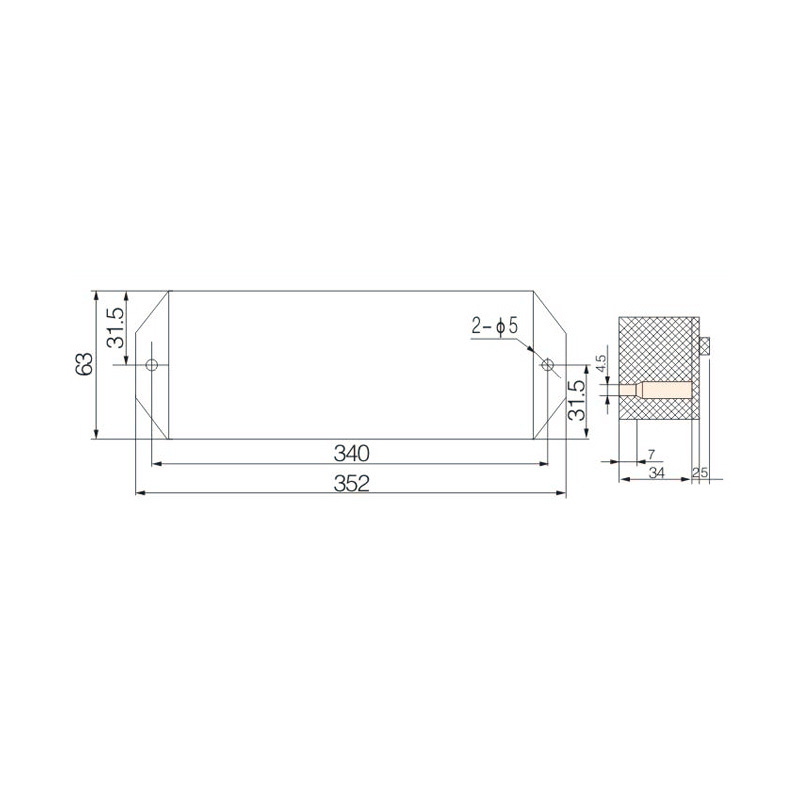

FJ6/JHD3-4/21 Three-Phase Four-Wire Twenty-One-Meter Household Terminal Block

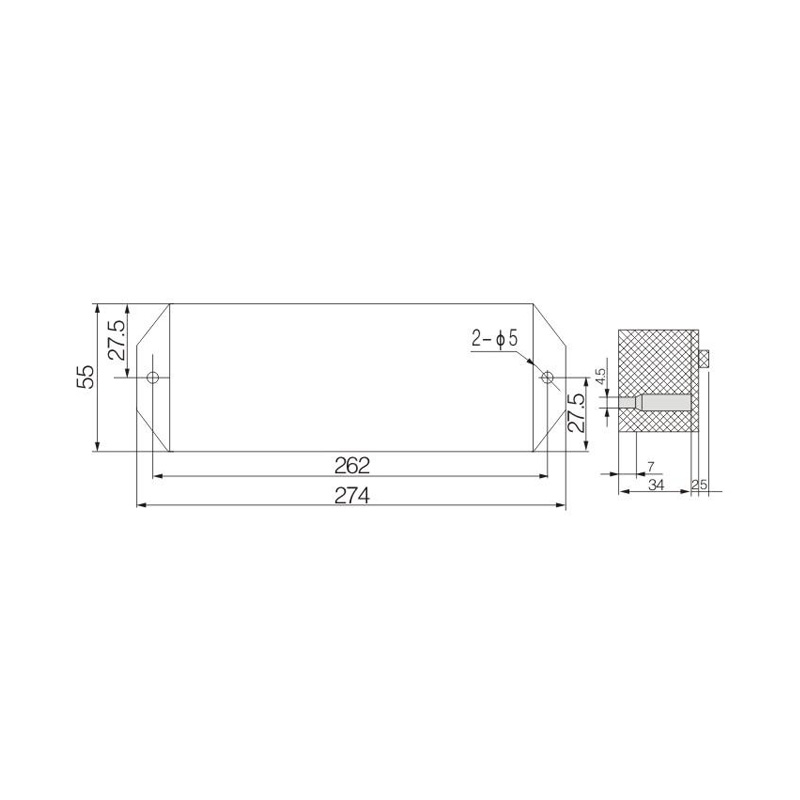

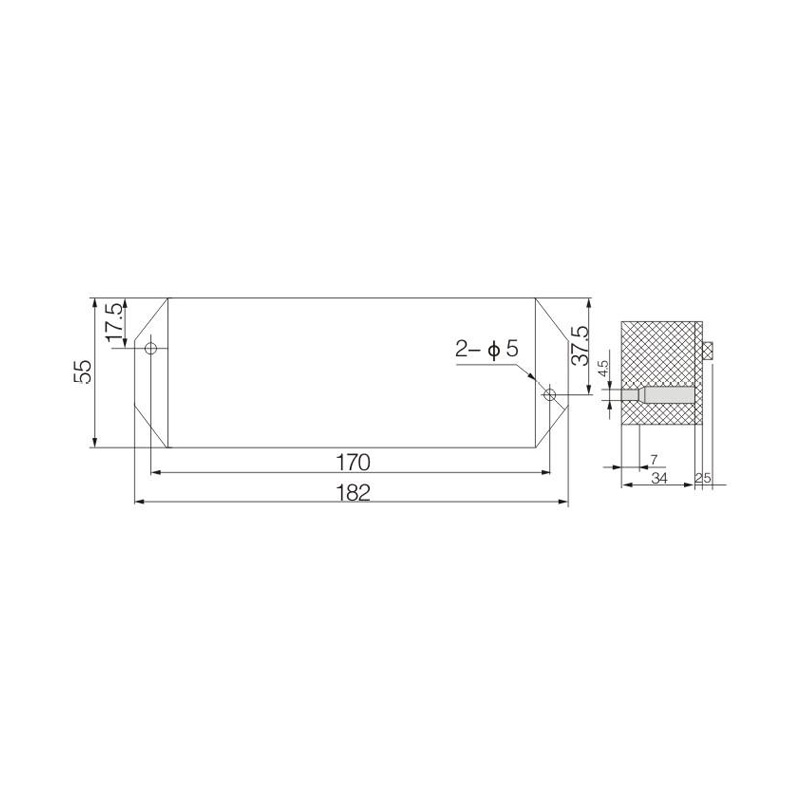

Model:FJ6/JHD3-4/21

Product name: Three-phase four-wire twenty-one-meter household terminal block

Order number: OrderNo.150154

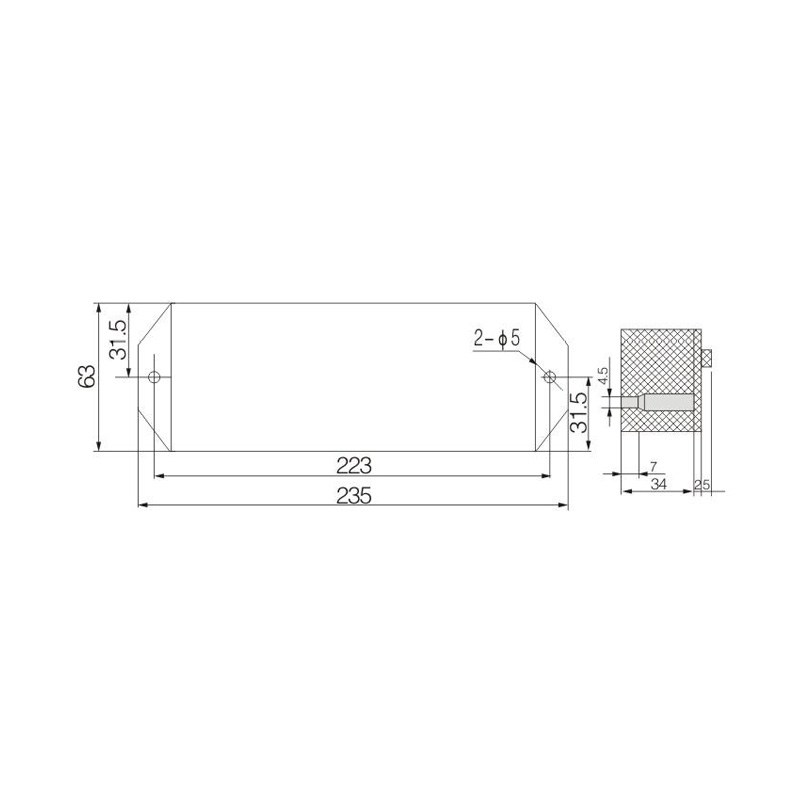

FJ6/JHD-2/C Three-Phase Twelve-Four-Meter Household Terminal Block

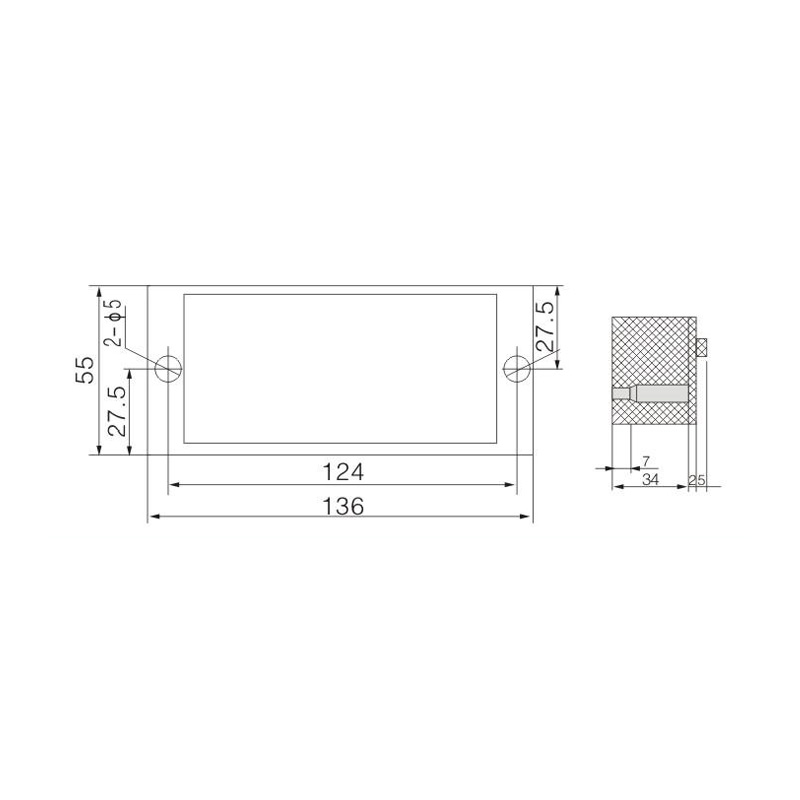

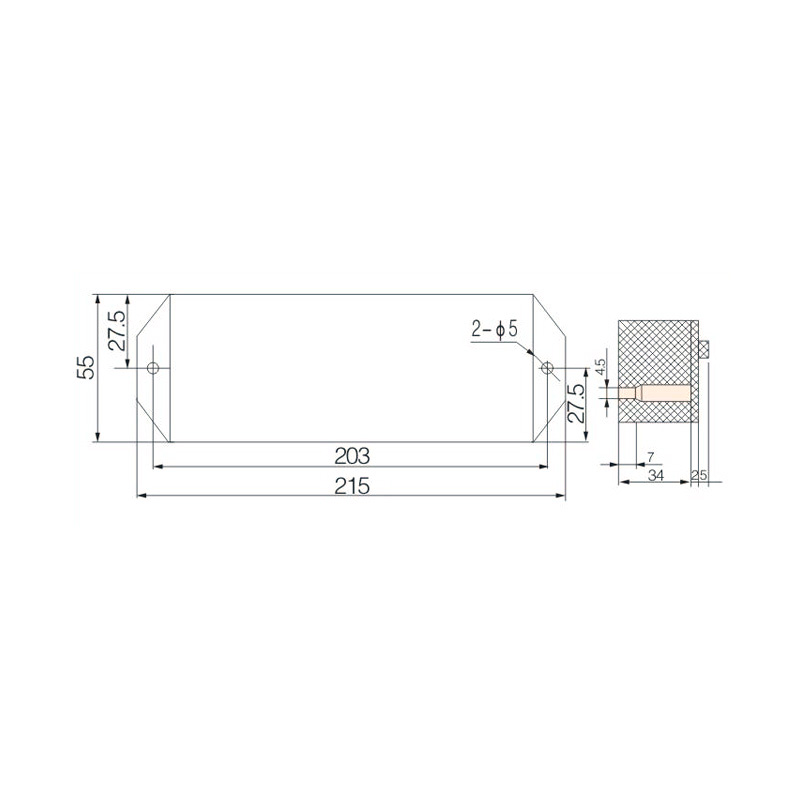

Model:FJ6/JHD-2/c

Product name: Three-phase twelve-four-meter household terminal block

Order number: OrderNo.150155

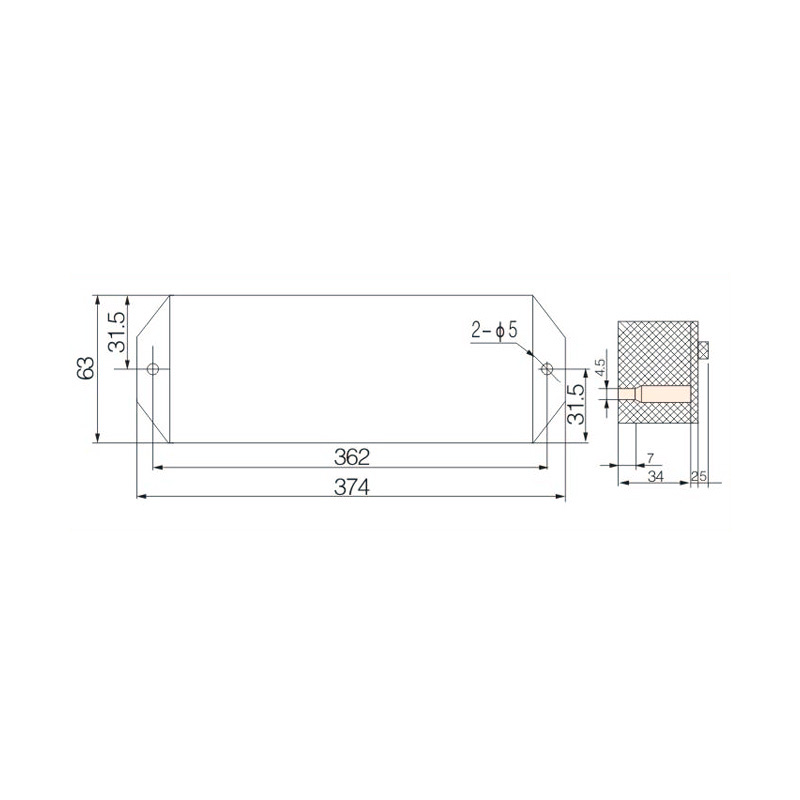

FJ6/JHD3-4/24 Three-Phase Four-Wire Twenty-Four-Meter Household Terminal Block

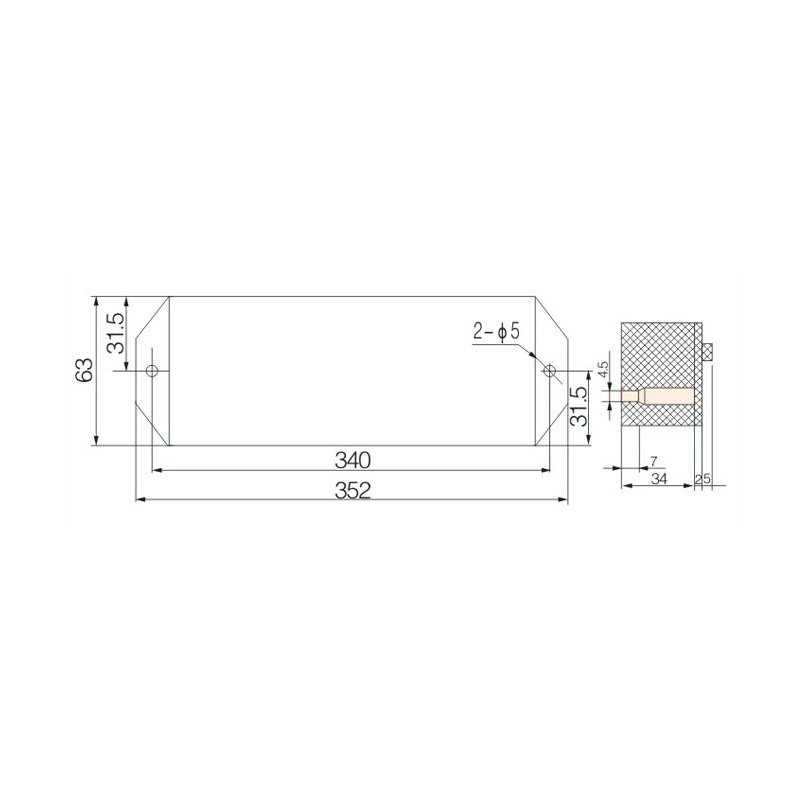

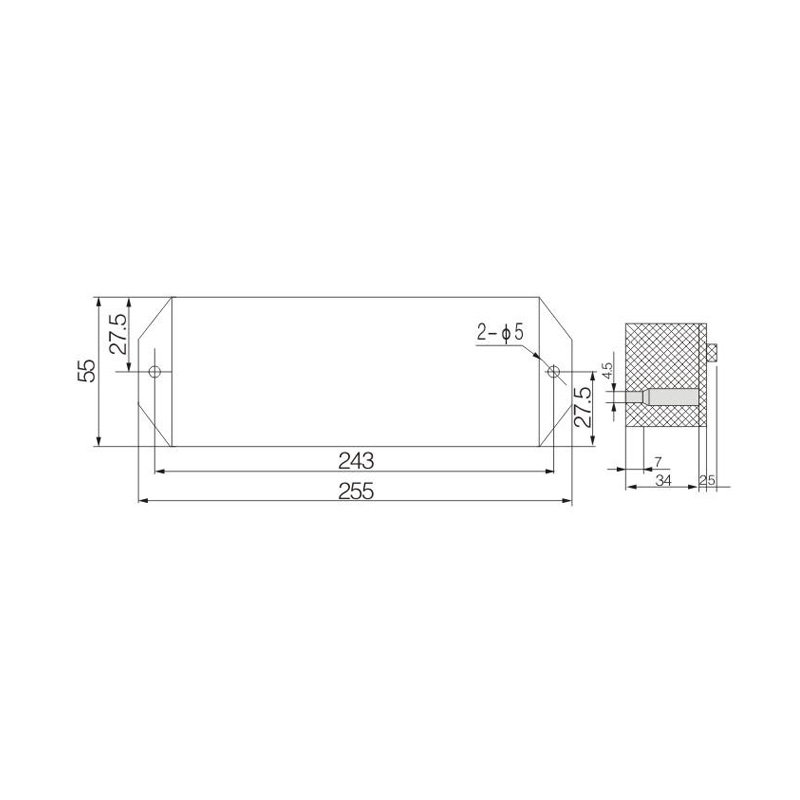

Model:FJ6/JHD3-4/24

Product name: Three-phase four-wire twenty-four-meter household terminal block

Order number: OrderNo.150156

FJ6/JHD-2/E Three-Phase Thirty-Meter Household Terminal Block

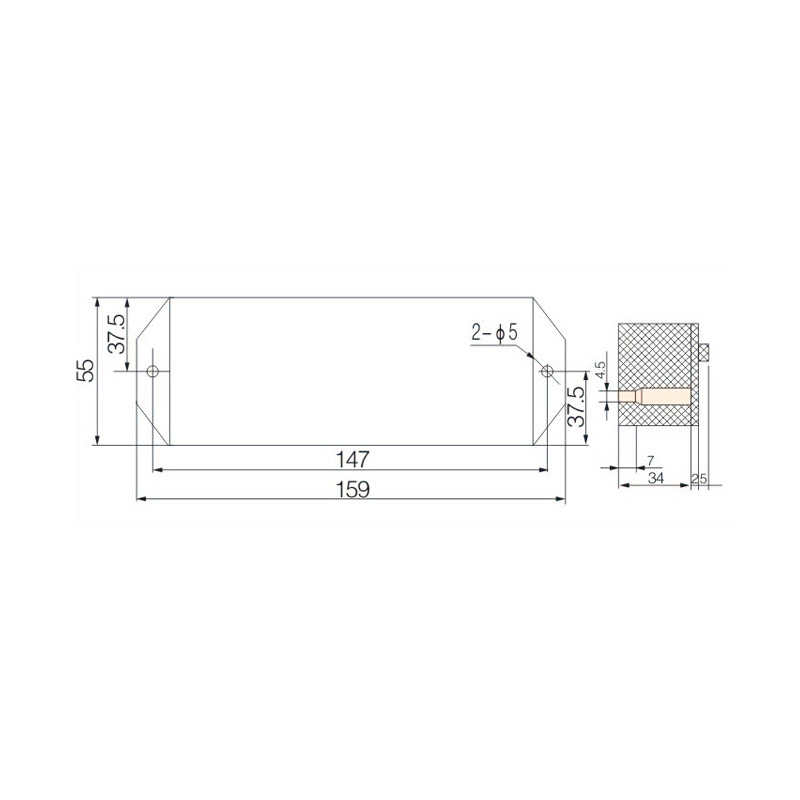

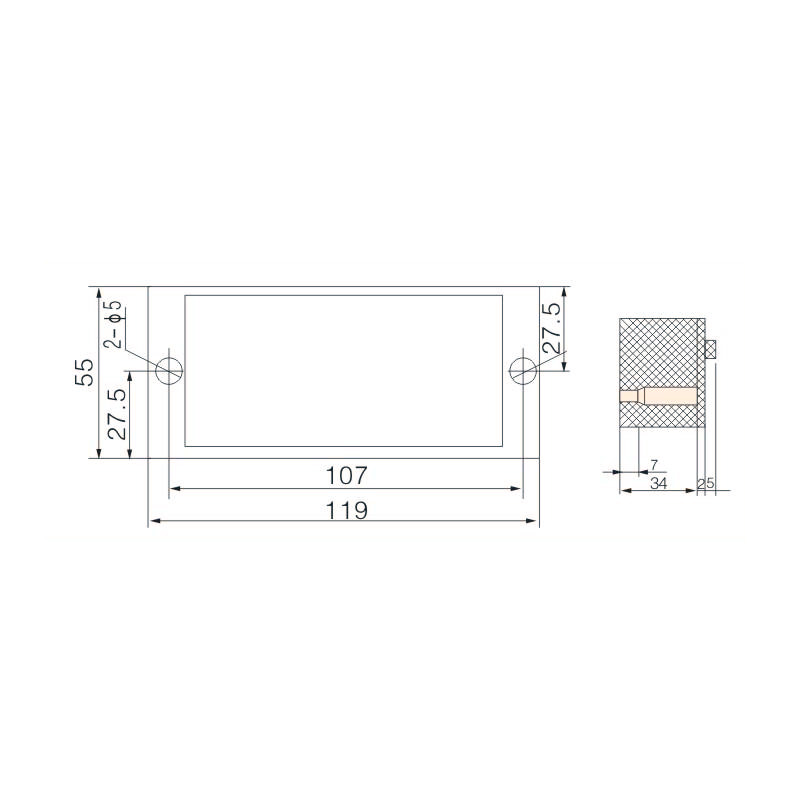

Model:FJ6/JHD-2/E

Product name: Three-phase thirty-meter household terminal block

Order number: OrderNo.150157

FJ6/JHD-2/F Three-Phase Thirty-Six-Meter Household Terminal Block

Model:FJ6/JHD-2/F

Product name: Three-phase thirty-six-meter household terminal block

Order number: OrderNo.150158

FJ6/JHD-4/8 Four-Inlet Eight-Outlet Terminal Block

Model:FJ6/JHD-4/8

Product name: Four-inlet eight-outlet terminal block

Order number: OrderNo.150159

FJ6/JHD-4/12 Four-Inlet Twelve-Outlet Terminal Block

Model:FJ6/JHD-4/12

Product name: Four-inlet twelve-outlet terminal block

Order number: OrderNo.150160

FJ6/JHD-4/16 Four-Inlet Sixteen-Outlet Terminal Block

Model:FJ6/JHD-4/16

Product name: Four-inlet sixteen-outlet terminal block

Order number: OrderNo.150161

FJ6/JHD-4/20 Four-Inlet Twenty-Meter Terminal Block

Model:FJ6/JHD-4/20

Product name: Four-inlet twenty-meter terminal block

Order number: OrderNo.150162

FJ6/JHD-4/24 Four-Inlet Twelve-Four-Meter Terminal Block

Model:FJ6/JHD-4/24

Product name: Four-inlet twelve-four-meter terminal block

Order number: OrderNo.150163

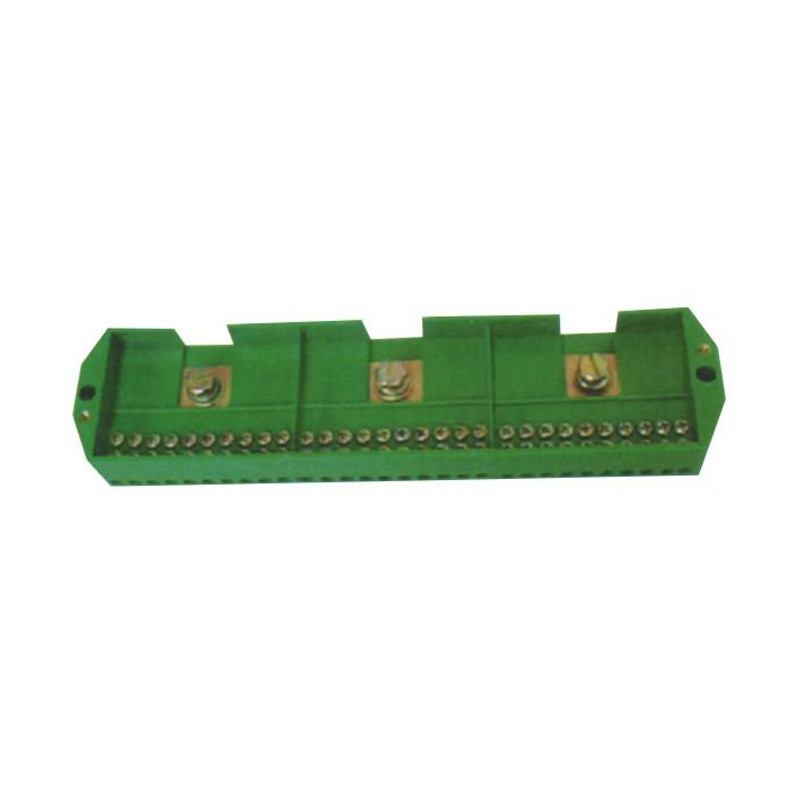

FJ6/JHD-2 Three-Inlet three-Outlet Heavy Current Terminal Block

Model:FJ6/JHD-2

Product name: Three-inlet three-outlet heavy current terminal block

Order number: OrderNo.150164

FJ6/JHD-2/C Four-Inlet Four-Outlet Heavy Current Terminal Block

Model:FJ6/JHD-2/c

Product name: Four-inlet four-outlet heavy current terminal block

Order number: OrderNo.150165

Search

Categories

-

Energy Measuring Terminal Block(314)

- Energy Measuring Joint Terminal Block(16)

- Polycarbonate Energy Measuring Terminal Block(24)

- Standard Wiring Energy Measuring Terminal Block(4)

- Transparent Shell Energy Measuring Terminal Block(6)

- Multifunctional Test Energy Measuring Terminal Block(10)

- Intelligent Safety Energy Measuring Terminal Block(6)

- Single-Phase Multi-Circuit Output Terminal Block(12)

- Self-Elevating Metering Box Terminal Block(7)

- One Household One-Meter Meter Box Dedicated Terminal Block(56)

- Three-Phase Metering Box Dedicated Terminal Block(24)

- Repeatable Grounding Line Terminal Block(20)

- Terminal Block for One-Inlet Multi-Outlet Metering Box(15)

- Closed Terminal Block(11)

- Heavy Current Terminal Block(48)

- Self-Boosting Terminal Block(5)

- Intelligent Self-Locking Terminal Block(3)

- Tool-Free Crimping Type Terminal Block(5)

- Wide Range of Wire Diameters Terminal Block(5)

- Combined Type Energy Measuring Terminal Block(37)

-

Switch Terminal Block(55)

- Pin-Type Incoming Line Switch Terminal Block(4)

- Multi-Way Connection Switch Terminal Block(4)

- Plug-pin Switch Terminal Block(7)

- Combined Type Switch Terminal Block(7)

- High Contact Cross Section Switch Terminal Block(7)

- Wide Range Switch Terminal Block(11)

- One Way in Switch Terminal Block(12)

- Equipped with Circuit Breaker Switch Terminal(3)

-

Heavy-current Terminal Block(631)

- Modular Building Block Terminal Block(156)

- Spherical Non-Destructive Crimp Terminal(120)

- Dual-Mode Connection Electrical Terminal(90)

- Anti-Electricity-Theft Terminal Block(74)

- Convenient Connection Terminal Block(12)

- High-Contact Section Terminal Block(12)

- Wide Range of Wire Diameters Neutral Line Terminal(9)

- Heavy-Current Neutral Line Terminal(9)

- Upper and Lower Rows of Neutral Terminal(2)

- Independent Neutral Line Terminal(7)

- Nose-Type Neutral Line Terminal(7)

- Rail Type Neutral Line Terminal(9)

- Fixed Neutral Line Terminal(12)

- Double Rail Assembly Electrical Terminal(19)

- Blue Jack-Up Terminal(6)

- Black Base Copper Bar Terminal(5)

- Compact Terminal Block(16)

- Precision Terminal Block(23)

- U-Shaped Harpoon Terminal(2)

- Grounding Metering Box Terminal Block(12)

- High-Performance Terminal Block(19)

- Multifunctional Terminal Block(10)

- Din Rail Terminal Block(76)

- Watt-hour Meter Connector(49)

-

Energy Meter Accessories(116)

-

-

Secure connections are essential for reliable electrical distribution, especially when installing a High-performance Terminal Bloc...

READ MORE -

For engineers and panel builders striving for both efficiency and reliability, wiring errors remain a persistent headache — even w...

READ MORE -

In modern electrical systems, a High-performance Terminal Block plays a critical role in ensuring secure and reliable connections ...

READ MORE -

When building or maintaining electrical systems, one frequently overlooked but critical factor is matching the conductor size to t...

READ MORE -

Effective electrical connections depend on more than simply matching cable sizes. Whether you’re securing a power conductor with a...

READ MORE

What Are The Potential Malfunctions Of a Three-Phase Metering Box Dedicated Terminal Block?

The three-phase metering box dedicated terminal block is designed to provide secure connections for metering and energy distribution. However, like any component, it can experience malfunctions if not properly installed or maintained. Below are several potential issues.

Loose or Weak Connections

One of the common malfunctions occurs when connections within the terminal block become loose. Over time, vibrations, thermal expansion, or improper tightening during installation can weakened contact points. This can cause intermittent faults, inaccurate energy measurement, or in some cases overheating. Regular inspection of terminal torque and conductor positioning helps reduce this risk.

Overheating of Contacts

If current loads exceed the rated capacity or if contact pressure is insufficient, heat can build up in the terminals. Prolonged overheating may result in insulation damage or deterioration of conductor surfaces. This not only affects measurement accuracy but also impacts long-term safety. Ensuring proper load distribution and using terminal blocks designed for the system's rated current is essential.

Insulation Degradation

Exposure to high temperatures, humidity, or corrosive environments may cause the insulating material of the terminal block to degrade. When insulation weakens, there is an increased risk of short circuits or unintended current leakage. Choosing materials suited for the operating environment helps maintain performance over time.

Measurement Inaccuracy

Dedicated terminal blocks in metering boxes play an important role in ensuring correct readings. If the terminals suffer from poor contact or mechanical damage, it may incorrect data being transmitted to the metering device. This can affect energy billing and system monitoring. Routine calibration and verification checks are recommended to ensure accuracy.

Mechanical Wear and Damage

Repeated tightening and loosening of screws, improper handling during installation, or external impacts can physically damage the terminal block. Cracked housings or worn-out clamping mechanisms compromise reliability. Careful handling and following installation guidelines help minimize such malfunctions.

These possible malfunctions underline the importance of proper installation, regular maintenance, and the selection of high-quality components for three-phase metering applications.

What Design Considerations Should Be Taken Into Account When Designing a 3-Pole Distribution Block?

The 3-pole distribution block plays a vital role in power management by distributing electricity from a single source to multiple circuits. To ensure efficiency and safety, several design considerations should be taken into account.

1. Electrical Capacity and Load Handling

The consideration in designing a 3-pole distribution block is ensuring it can handle the intended electrical load. Current and voltage ratings must align with the demands of the system to avoid overheating and voltage drops. The block should provide reliable performance under continuous operation and be capable of accommodating peak loads without compromising safety. Careful attention to rated capacity prevents premature wear and helps maintain stability in power distribution.

2. Safety and Insulation Features

Another essential design factor is safety. Distribution blocks should include adequate insulation to prevent accidental contact and reduce the risk of short circuits. Protective covers and flame-resistant materials further enhance safety in demanding environments. Clear labeling of connection points also supports correct installation and minimizes human error. By prioritizing insulation and protection in the design phase, the 3-pole distribution block contributes to safer and more dependable system operation, especially in commercial or industrial applications where high loads are common.

3. Flexibility and Space Optimization

Flexibility in design is equally important. A well-designed distribution block should accept various conductor sizes, allowing it to serve multiple applications without modification. Compact design supports efficient use of panel space, ensuring that wiring remains organized and accessible. This not only improves the appearance of electrical panels but also simplifies future maintenance or system expansion. Flexibility and space optimization make the 3-pole distribution block a practical choice for modern electrical installations where both performance and adaptability are priorities.

English

English Español

Español عربى

عربى