Integrating wired connectivity into the era of automation and digital networking involves more than just traditional hardware. A H...

READ MORESingle-Phase Multi-Circuit Output Terminal Block Manufacturer

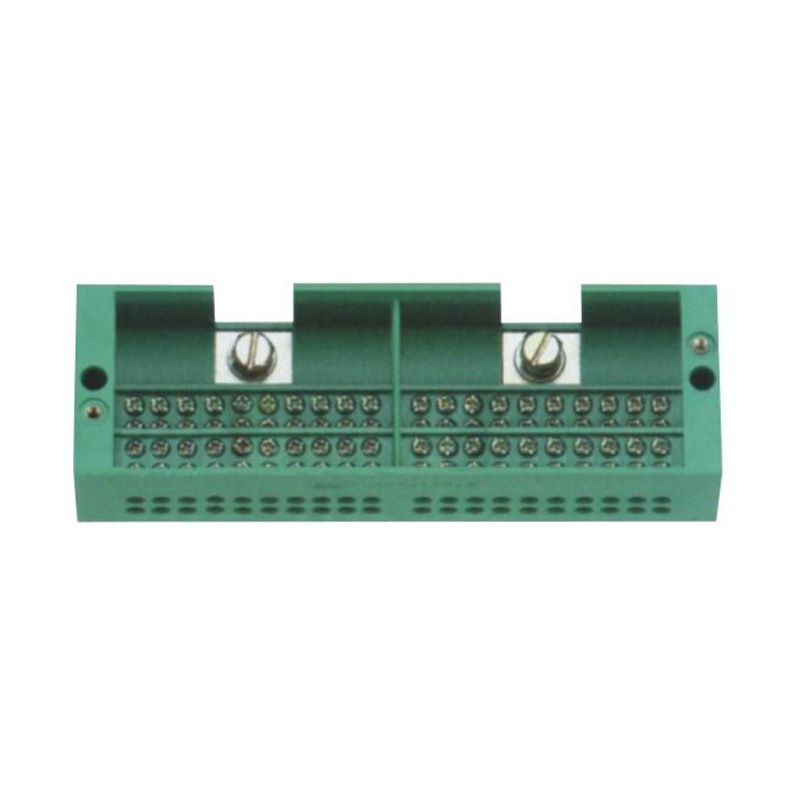

Single-Phase Multi-Circuit Output Terminal Blocks are professionally used for distributing single-phase electrical power across multiple circuits in a variety of electrical systems and installations. These terminal blocks are specifically designed for applications that require efficient and reliable power distribution to multiple outlets or devices from a single-phase power source. They are ideal for wiring in control panels, distribution boards, and other electrical equipment where multiple circuits need to be managed effectively.The insulation voltage is 690V, and the rated voltage is 380V. These terminal blocks feature a compact and secure design that allows for stable connections to multiple circuits without the need for excessive wiring or additional conductors. They ensure minimal voltage drop and maximum reliability in power distribution.

Single-Phase Multi-Circuit Output Terminal Blocks are currently a novel product offering a convenient and highly reliable solution for multi-circuit power distribution. They simplify the wiring process, making installation and maintenance easier while ensuring efficient power delivery to multiple circuits.

The transparent cover allows for clear, direct visibility of the terminal connections, making it easier for electricians and maintenance personnel to inspect and verify connections without the need for additional tools or disassembly. This feature is particularly beneficial for quick troubleshooting and maintenance, reducing downtime and ensuring system reliability.

The transparent cover is made from high-quality, impact-resistant material that protects the terminal connections from environmental factors such as dust, moisture, and physical damage. This protection extends the lifespan of the terminal block and reduces the risk of short circuits and other electrical hazards.

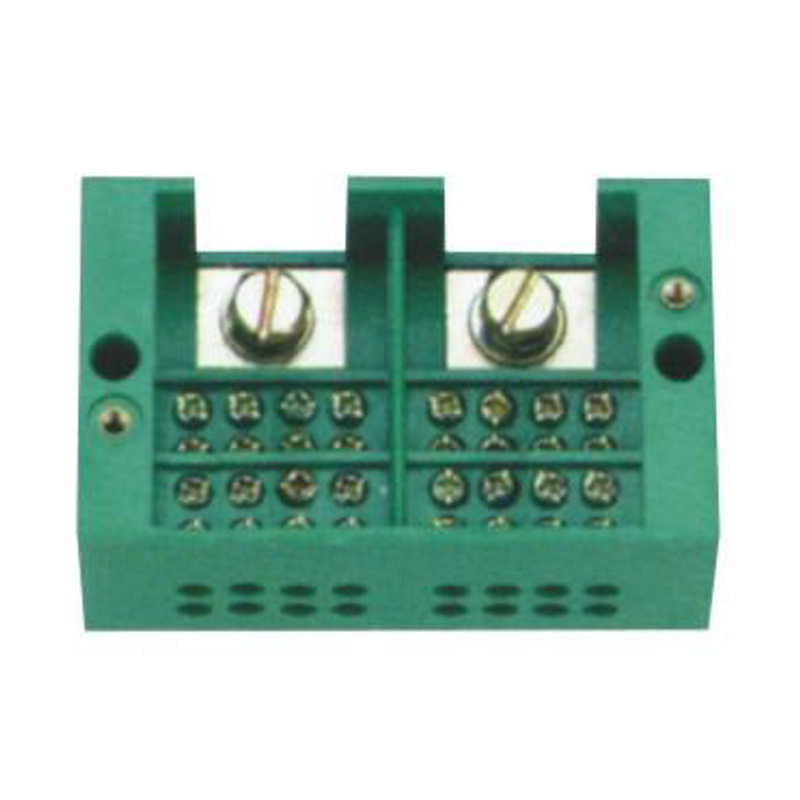

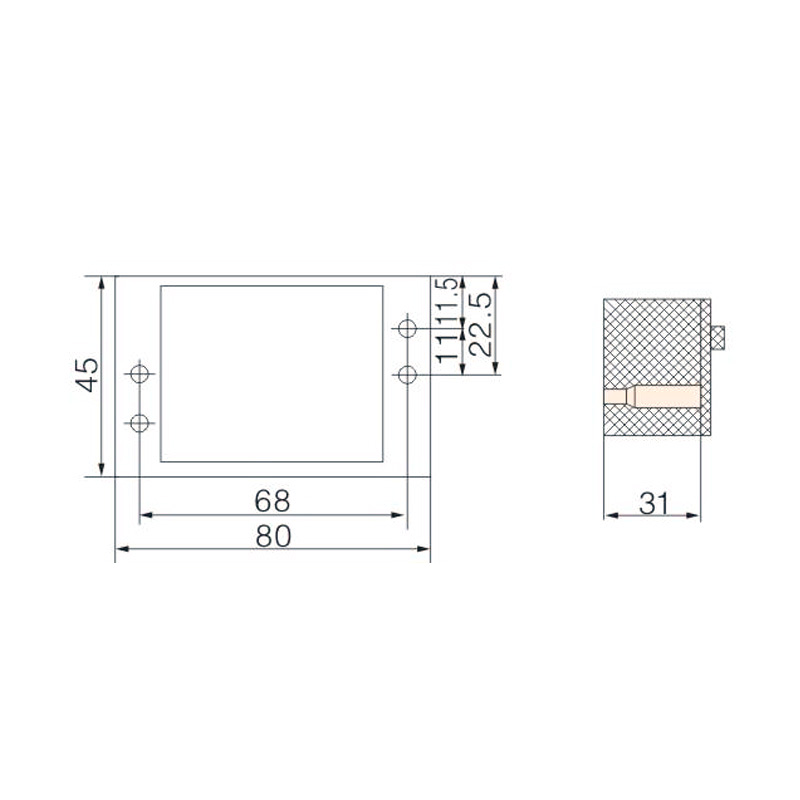

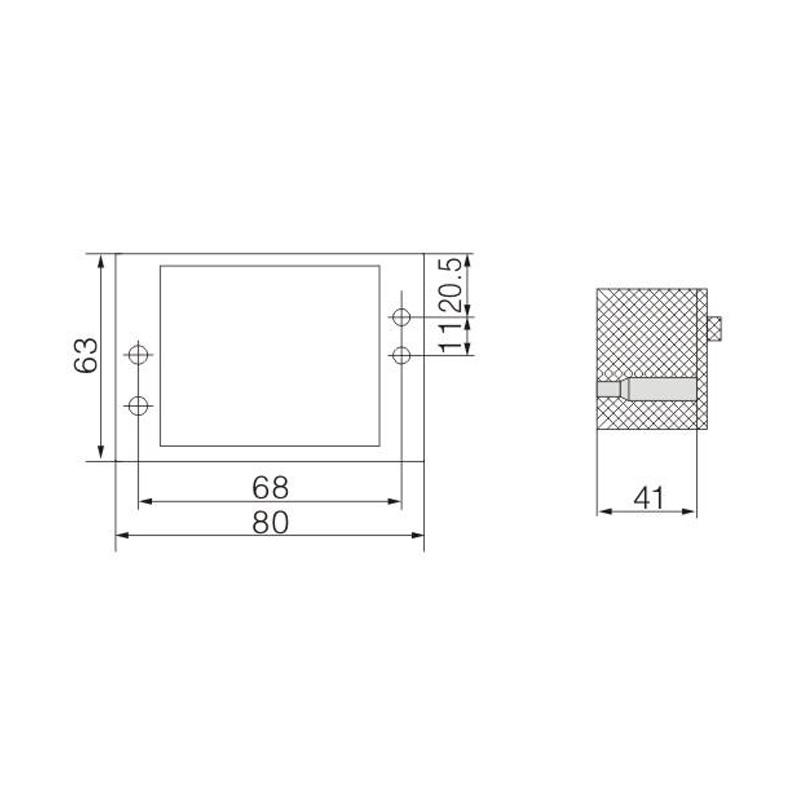

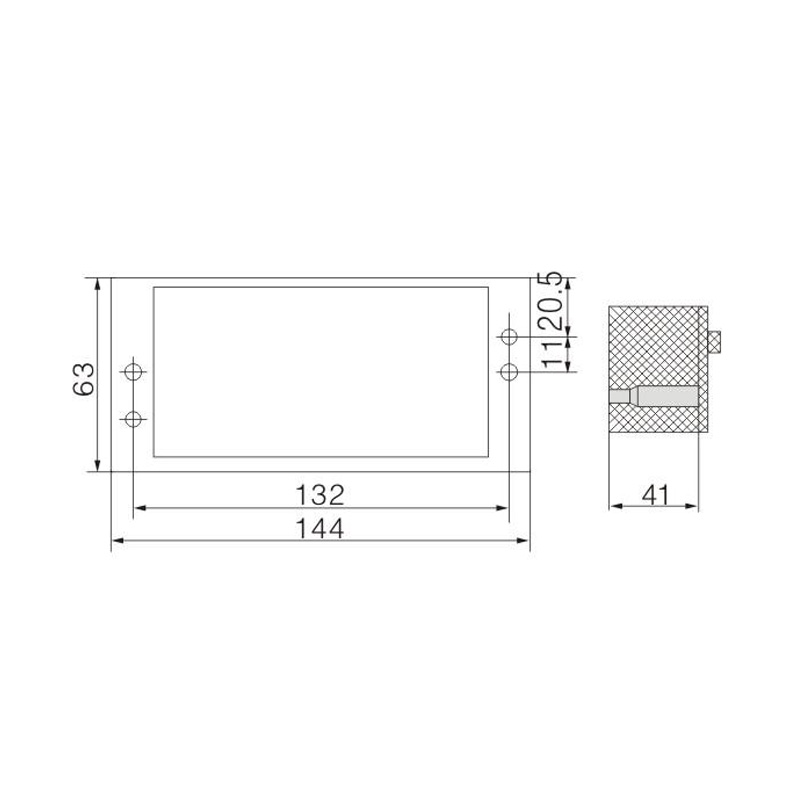

FJ6/HD2-6/B Terminal Block for Single-Phase Metering Box

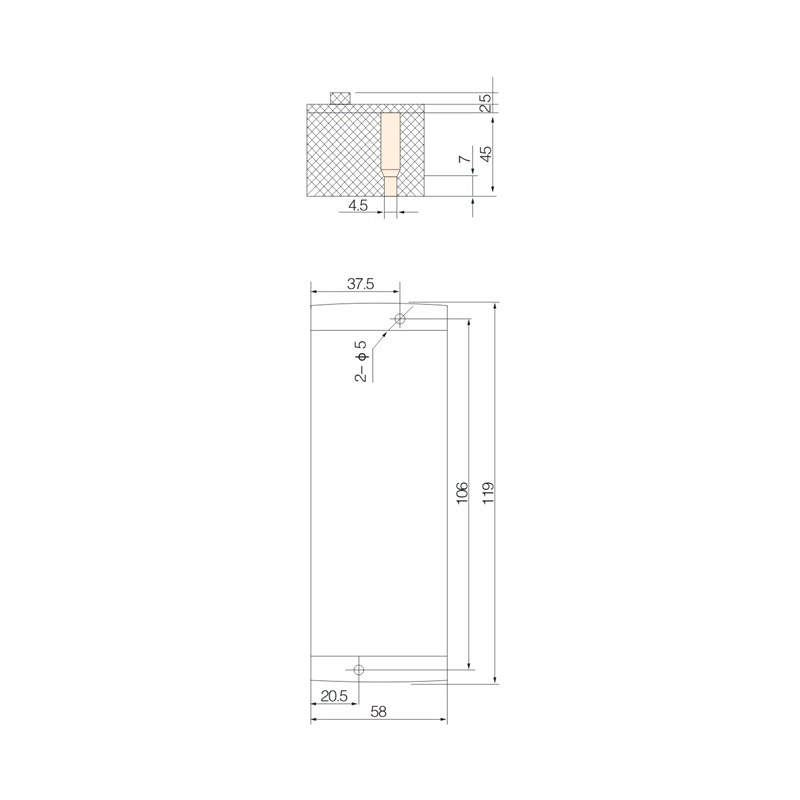

Model:FJ6/HD2-6/B

Product name: Single-phase two-inlet six-outlet terminal block

Order number: OrderNo.150067

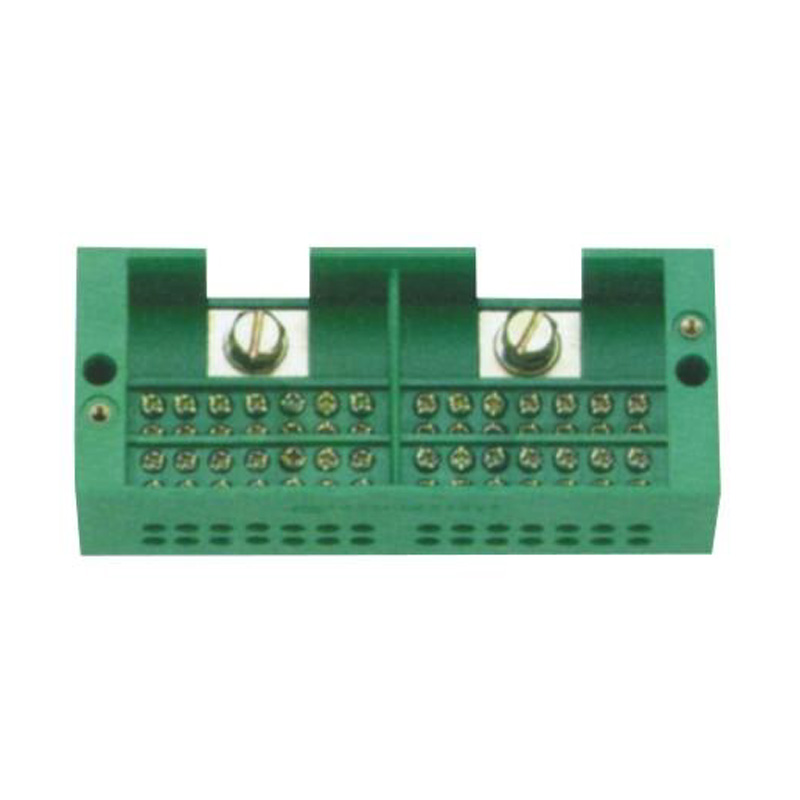

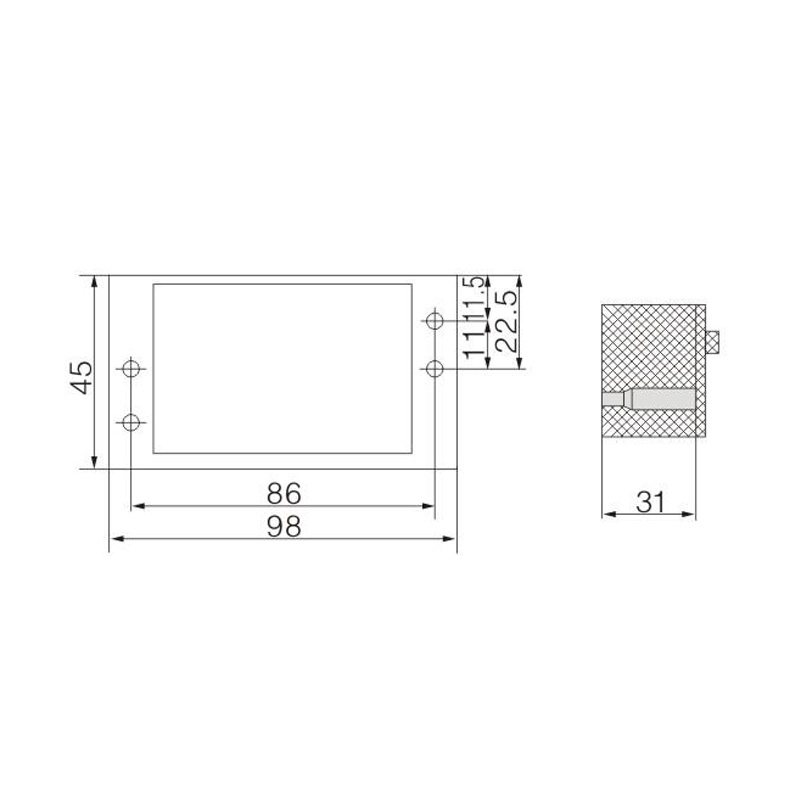

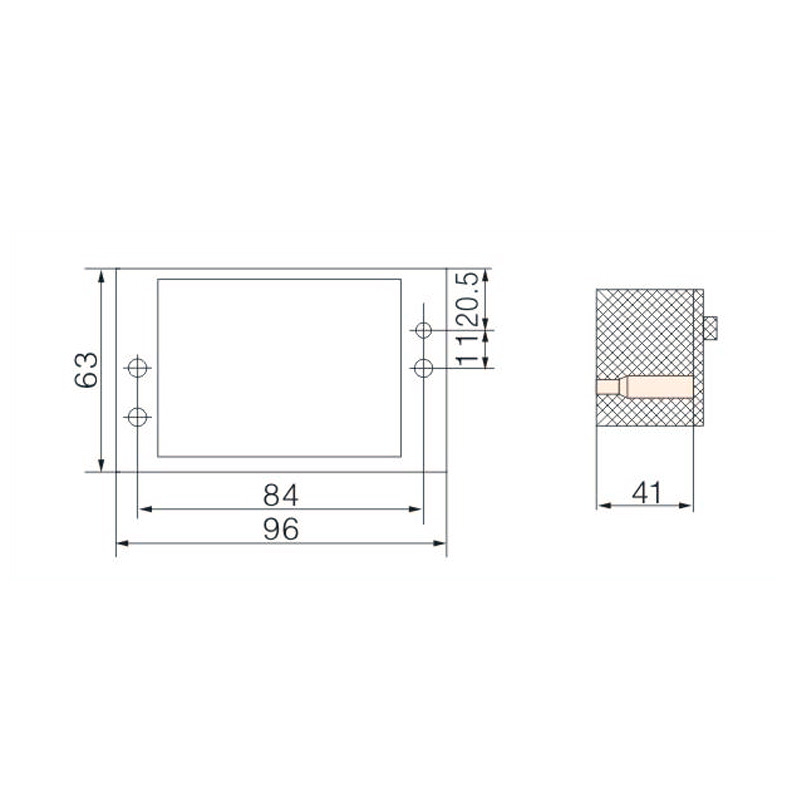

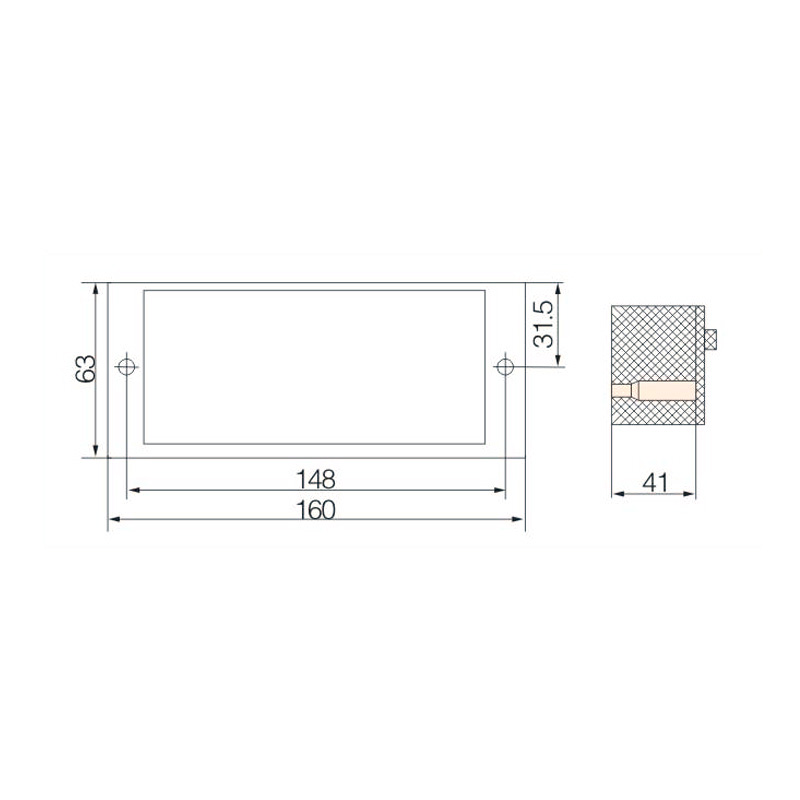

FJ6/HD2-8/B Terminal Block for Single-Phase Metering Box

Model:FJ6/HD2-8/B

Product name: Single-phase two-inlet eight-outlet terminal block

Order number: OrderNo.150068

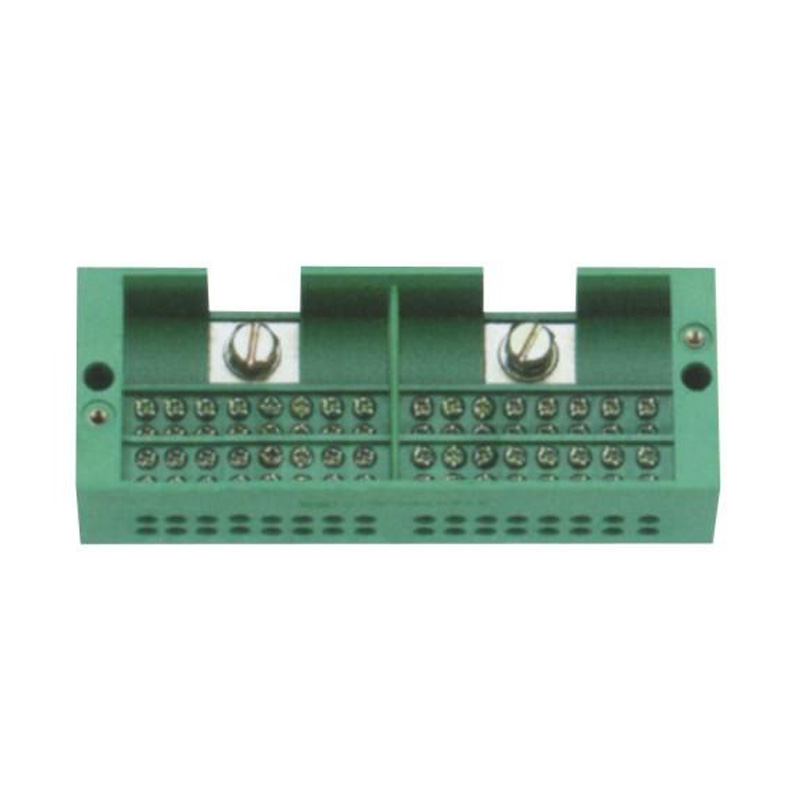

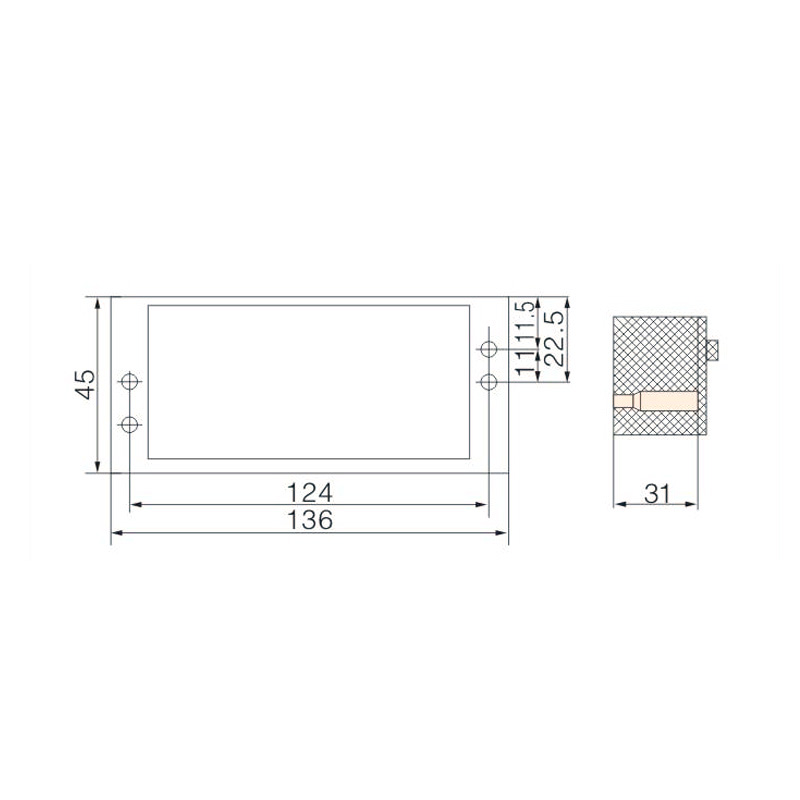

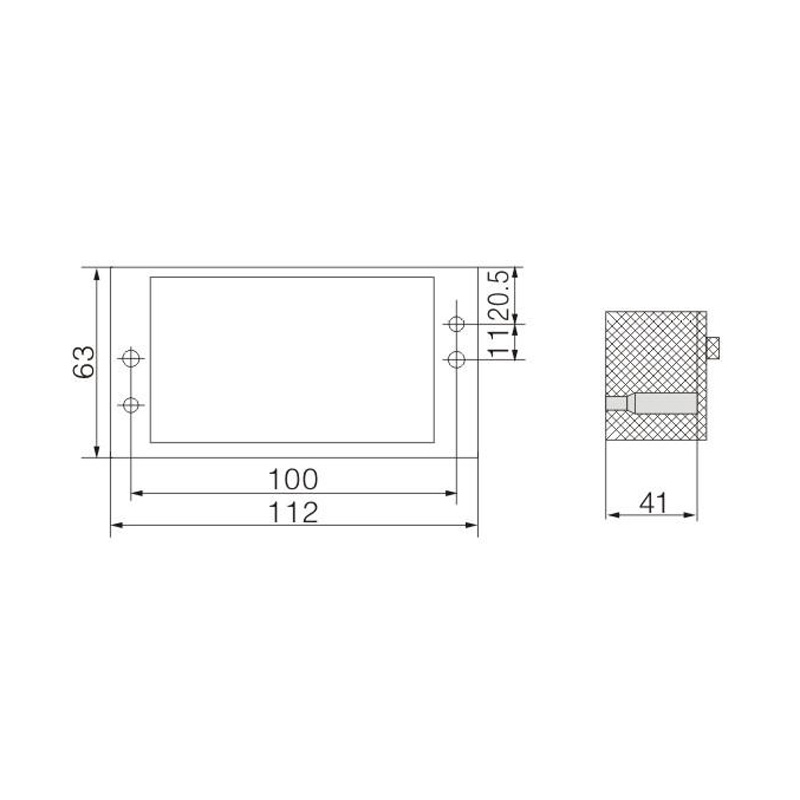

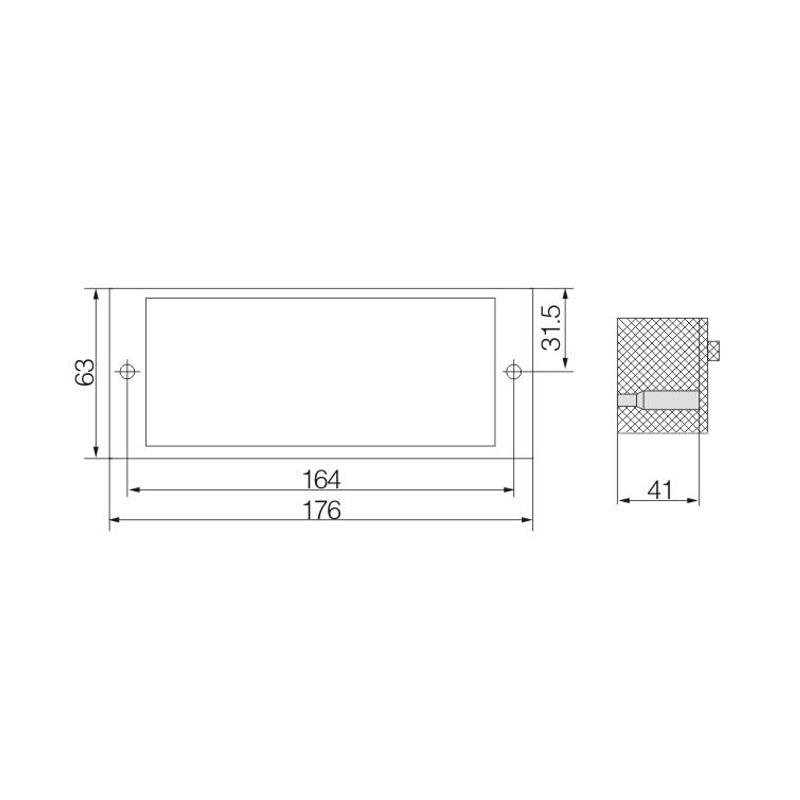

FJ6/HD2-12/B Terminal Block for Single-Phase Metering Box

Model:FJ6/HD2-12/B

Product name: Single-phase two-inlet tweleve-meter-outlet terminal block

Order number: OrderNo.150069

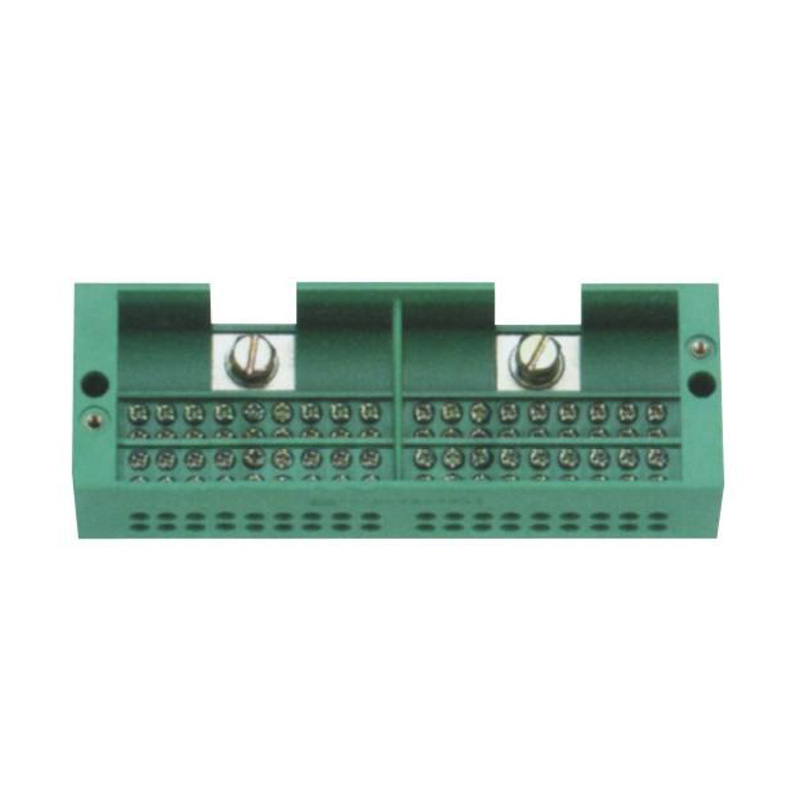

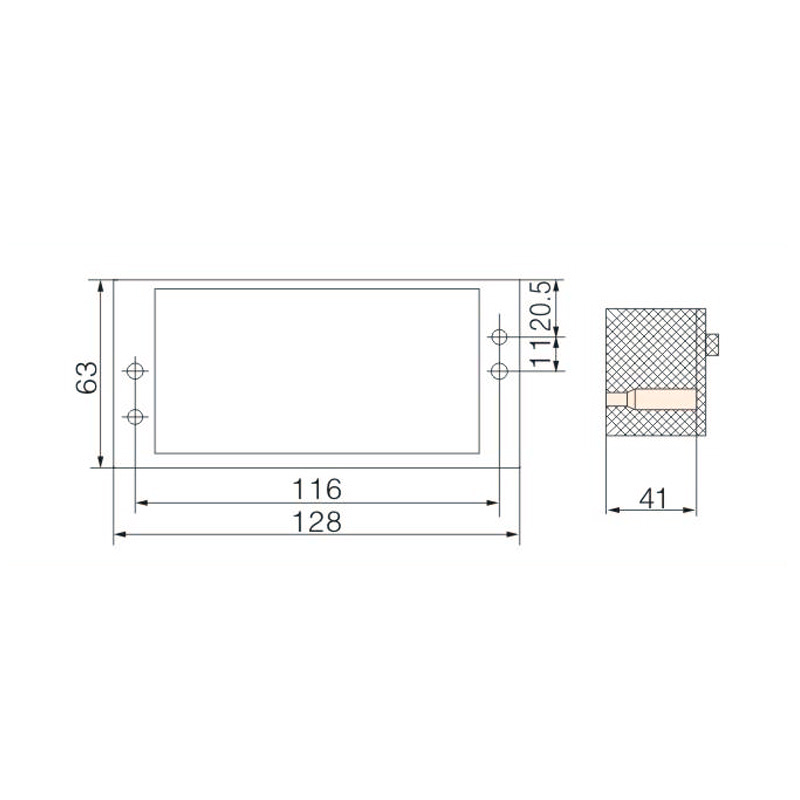

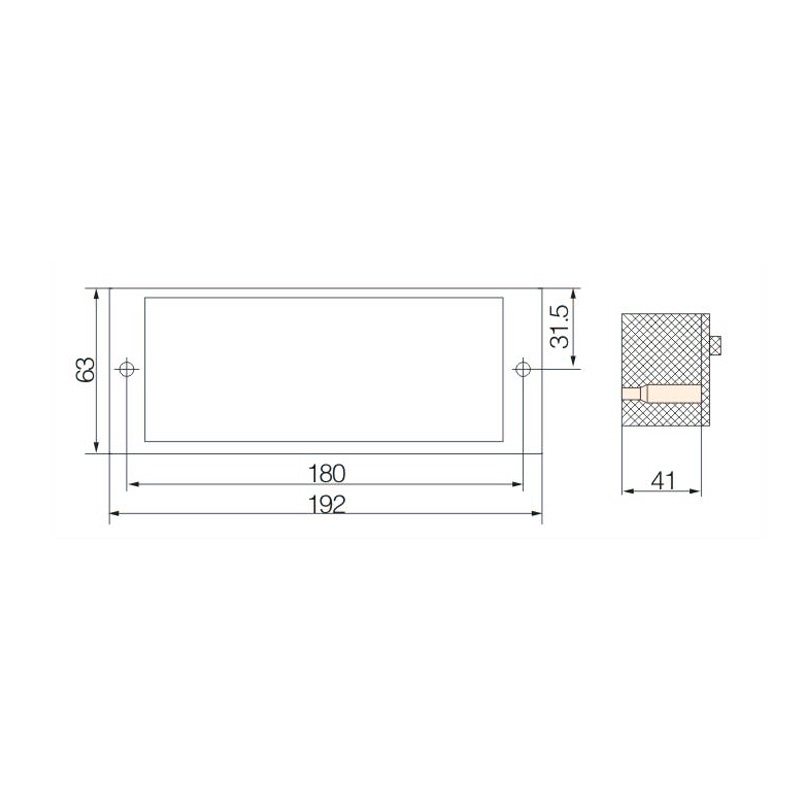

FJ6/HD2-12/C Terminal Block for Single-Phase Metering Box

Model:FJ6/HD2-12/C

Product name: Single-phase two-inlet tweleve-meter-outlet terminal block

Order number: OrderNo.150070

FJ6/HD2-16/C Terminal Block for Single-Phase Metering Box

Model:FJ6/HD2-16/C

Product name: Single-phase two-inlet sixteen-meter-outlet terminal block

Order number: OrderNo.150071

FJ6/HD2-20/C Terminal Block for Single-Phase Metering Box

Model:FJ6/HD2-20/C

Product name: Single-phase two-inlet twenty-meter-outlet terminal block

Order number: OrderNo.150072

FJ6/HD2-24/C Terminal Block for Single-Phase Metering Box

Model:FJ6/HD2-24/C

Product name: Single-phase two-inlet twenty-four-meter-outlet terminal block

Order number: OrderNo.150073

FJ6/HD2-28/C Terminal Block for Single-Phase Metering Box

Model:FJ6/HD2-28/C

Product name: Single-phase two-inlet twenty-eight-meter-outlet terminal block

Order number: OrderNo.150074

FJ6/HD2-32/C Terminal Block for Single-Phase Metering Box

Model:FJ6/HD2-32/C

Product name: Single-phase two-inlet thirty-two-meter-outlet terminal block

Order number: OrderNo.150075

FJ6/HD2-36/C Terminal Block for Single-Phase Metering Box

Model:FJ6/HD2-36/C

Product name: Single-phase two-inlet thirty-six-meter outlet terminal block

Order number: OrderNo.150076

FJ6/HD2-40/C Terminal Block for Single-Phase Metering Box

Model:FJ6/HD2-40/C

Product name: Single-phase two-inlet Forty-meter-outlet terminal block

Order number: OrderNo.150077

Search

Categories

-

Energy Measuring Terminal Block(314)

- Energy Measuring Joint Terminal Block(16)

- Polycarbonate Energy Measuring Terminal Block(24)

- Standard Wiring Energy Measuring Terminal Block(4)

- Transparent Shell Energy Measuring Terminal Block(6)

- Multifunctional Test Energy Measuring Terminal Block(10)

- Intelligent Safety Energy Measuring Terminal Block(6)

- Single-Phase Multi-Circuit Output Terminal Block(12)

- Self-Elevating Metering Box Terminal Block(7)

- One Household One-Meter Meter Box Dedicated Terminal Block(56)

- Three-Phase Metering Box Dedicated Terminal Block(24)

- Repeatable Grounding Line Terminal Block(20)

- Terminal Block for One-Inlet Multi-Outlet Metering Box(15)

- Closed Terminal Block(11)

- Heavy Current Terminal Block(48)

- Self-Boosting Terminal Block(5)

- Intelligent Self-Locking Terminal Block(3)

- Tool-Free Crimping Type Terminal Block(5)

- Wide Range of Wire Diameters Terminal Block(5)

- Combined Type Energy Measuring Terminal Block(37)

-

Switch Terminal Block(55)

- Pin-Type Incoming Line Switch Terminal Block(4)

- Multi-Way Connection Switch Terminal Block(4)

- Plug-pin Switch Terminal Block(7)

- Combined Type Switch Terminal Block(7)

- High Contact Cross Section Switch Terminal Block(7)

- Wide Range Switch Terminal Block(11)

- One Way in Switch Terminal Block(12)

- Equipped with Circuit Breaker Switch Terminal(3)

-

Heavy-current Terminal Block(631)

- Modular Building Block Terminal Block(156)

- Spherical Non-Destructive Crimp Terminal(120)

- Dual-Mode Connection Electrical Terminal(90)

- Anti-Electricity-Theft Terminal Block(74)

- Convenient Connection Terminal Block(12)

- High-Contact Section Terminal Block(12)

- Wide Range of Wire Diameters Neutral Line Terminal(9)

- Heavy-Current Neutral Line Terminal(9)

- Upper and Lower Rows of Neutral Terminal(2)

- Independent Neutral Line Terminal(7)

- Nose-Type Neutral Line Terminal(7)

- Rail Type Neutral Line Terminal(9)

- Fixed Neutral Line Terminal(12)

- Double Rail Assembly Electrical Terminal(19)

- Blue Jack-Up Terminal(6)

- Black Base Copper Bar Terminal(5)

- Compact Terminal Block(16)

- Precision Terminal Block(23)

- U-Shaped Harpoon Terminal(2)

- Grounding Metering Box Terminal Block(12)

- High-Performance Terminal Block(19)

- Multifunctional Terminal Block(10)

- Din Rail Terminal Block(76)

- Watt-hour Meter Connector(49)

-

Energy Meter Accessories(116)

-

-

Secure connections are essential for reliable electrical distribution, especially when installing a High-performance Terminal Bloc...

READ MORE -

For engineers and panel builders striving for both efficiency and reliability, wiring errors remain a persistent headache — even w...

READ MORE -

In modern electrical systems, a High-performance Terminal Block plays a critical role in ensuring secure and reliable connections ...

READ MORE -

When building or maintaining electrical systems, one frequently overlooked but critical factor is matching the conductor size to t...

READ MORE -

Effective electrical connections depend on more than simply matching cable sizes. Whether you’re securing a power conductor with a...

READ MORE

Do You Know About Single-Phase Multi-Circuit Output Terminal Blocks?

When designing electrical systems for control panels, machinery, or industrial equipment, space is often at a premium. This is where single-phase multi-circuit output terminal blocks prove invaluable. Essentially, they are modular blocks that consolidate multiple independent connection points—or circuits—for a single-phase power supply into a single, compact unit.

Imagine a scenario where you need to distribute power from one incoming wire to several different outgoing devices. Instead of creating multiple, space-consuming splices or installing several individual terminal blocks, a multi-circuit block provides a neat and organized solution. The incoming "feed" wire is connected to a common terminal, and then multiple output circuits are arranged side-by-side, allowing for efficient and logical power distribution.

The primary advantages are organization, safety, and significant space savings within an enclosure. They drastically reduce wiring clutter, which not only makes the panel look professional but also simplifies troubleshooting and maintenance. By consolidating connections, they minimize the risk of loose wires and potential short circuits. For electricians and technicians, these blocks streamline installation and modification processes, as all related connections are housed in one easily identifiable location. They are a testament to the principle that good design is about making complex systems simpler and more efficient.

What Are The Applications Of Green Screw Terminals?

You may have noticed terminal blocks with distinctive green screws or levers and wondered about their significance. This color coding is not merely aesthetic; it signifies a specific and crucial safety feature. Green terminals are universally designed for grounding and bonding applications.

Their primary purpose is to provide a highly reliable and secure connection for equipment grounding conductors. In any electrical system, the ground connection is the critical safety path that allows fault current to flow safely back to the source, tripping a breaker or blowing a fuse in the event of a short circuit. The integrity of this connection is non-negotiable. Green screw terminals are often built to a higher mechanical and electrical standard to ensure this integrity is maintained. They typically feature a robust clamping mechanism, such as a heavy-duty screw or a serrated washer, to bite into the conductor and create a low-resistance, gas-tight connection that will not loosen over time due to vibration or thermal cycling.

You will find these green terminals throughout industrial control panels, power distribution systems, and machinery, connecting the green or bare copper ground wires. They are also used for bonding, which involves connecting metal parts of an enclosure or structure to the ground system to ensure they are always at the same potential and cannot become energized. This application is vital for preventing electric shock. The visual green cue instantly alerts an installer or inspector to the terminal's dedicated safety function, ensuring it is used correctly.

What Is The Difference Between PCB Terminal Blocks And Others?

Terminal blocks can be broadly categorized by how they are mounted, and this distinction defines their application. The common types are PCB-mounted, DIN rail-mounted, and barrier strips. Understanding their differences is key to selecting the right one for the job.

PCB Terminal Blocks: As the name implies, these are designed to be soldered directly onto a printed circuit board (PCB). They act as an interface between the internal circuitry of the board and the external world. Wires from power sources, sensors, or actuators are connected to the block, which feeds the signal or power directly into the board via soldered pins. They are typically small, low-profile, and designed for lower voltage and current applications, such as in consumer electronics, telecommunications devices, and industrial control boards.

DIN Rail-Mounted Blocks: These are the workhorses of industrial control panels. They snap onto a standard metal rail, allowing for the quick assembly and modular arrangement of dozens or even hundreds of connections in a single enclosure. They are designed for higher power levels, easier wiring, and organization. Their modular nature means they can be easily added, removed, or rearranged without tools in some cases, making system modifications simple.

Barrier Strips: Often used in applications where vibration is a concern, such as in automotive or marine environments, barrier strips are individual blocks that are screwed directly to a chassis or panel. A solid insulating barrier separates each connection point. They are known for their ruggedness and ability to handle higher voltages and larger wire gauges than many PCB blocks.

English

English Español

Español عربى

عربى