Integrating wired connectivity into the era of automation and digital networking involves more than just traditional hardware. A H...

READ MOREIntelligent Self-Locking Terminal Block Manufacturer

The Intelligent Self-Locking Terminal Block meets the requirements of safety protection, beauty, convenient wiring, and stable installation. It is used for the rated voltage of 660V and frequency of 50Hz or 60Hz. The maximum cross-section of the wire connecting wire at the inlet is 2.5-50 (70) square mm, and the wire connecting wire at the outlet is 0.75-16 square mm. This product adopts the direct crimping method of self-lifting screw crimping clamp. A self-locking is formed between the crimp clamp and the screw, and it will not loosen and fall off under vibration conditions, which will bring you maintenance-free convenience during long-term use.

The terminal blocks are made from outstanding materials that ensure durability and resistance to environmental factors such as corrosion, ensuring long-lasting performance in various conditions.

The construction of these terminal blocks is designed to withstand high mechanical stress, which is common in industrial settings. This ensures that the connections remain secure and intact under tough conditions.

These terminal blocks are versatile and can be used in a variety of applications, including but not limited to power distribution, control systems, and measurement equipment in industrial, commercial, and residential settings.

The design of the terminal blocks allows for quick and easy installation, reducing downtime and labor costs. Maintenance is also simplified due to the accessible design and robustness of the terminal blocks.

Capable of handling high currents, these terminal blocks are ideal for applications where heavy loads are common, ensuring that the connections can handle the demands without overheating or failing.

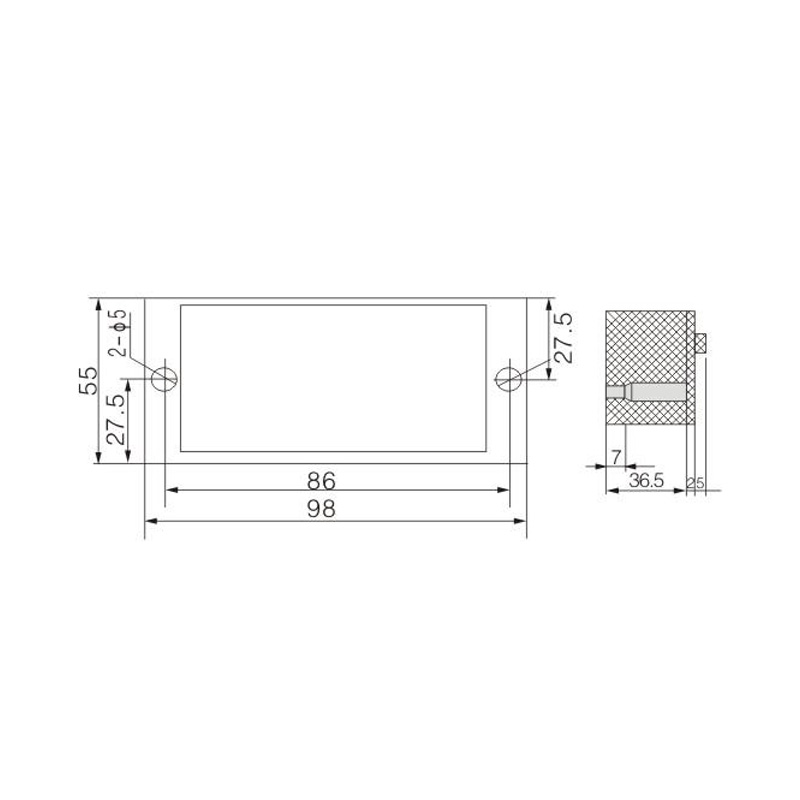

FJ6/JHD-6/A Terminal Blocks for Measuring Box

Model:FJ6/JHD-6/a

Product name: Two-inlet eight-outlet(four-meter household)

Order number: OrderNo.150576

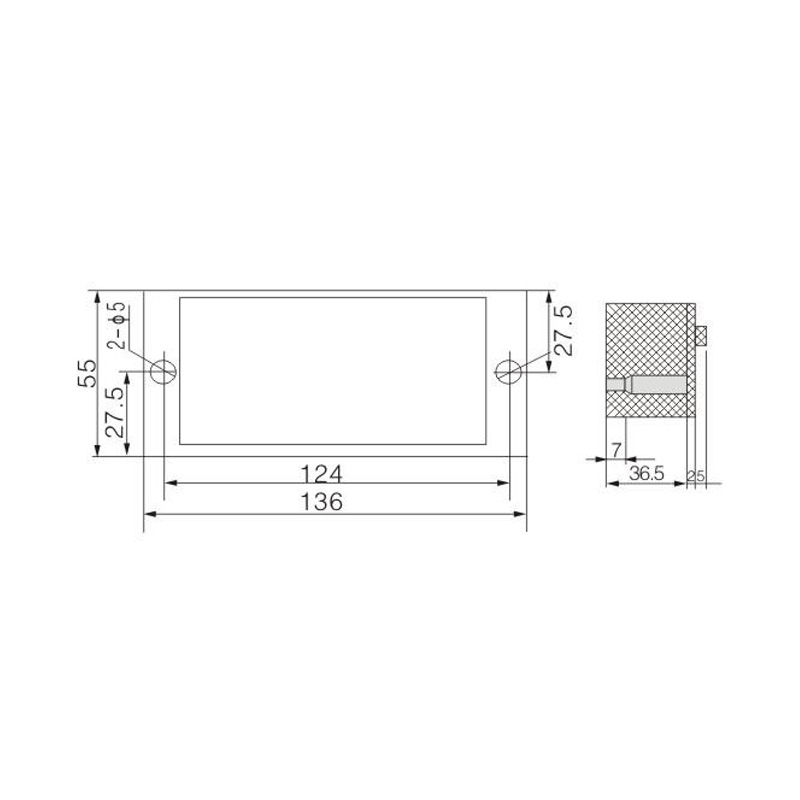

FJ6/JHD-6/B Terminal Blocks for Measuring Box

Model:FJ6/JHD-6/B

Product name: Two-inlet twelve-outlet(six-meter household)

Order number: OrderNo.150577

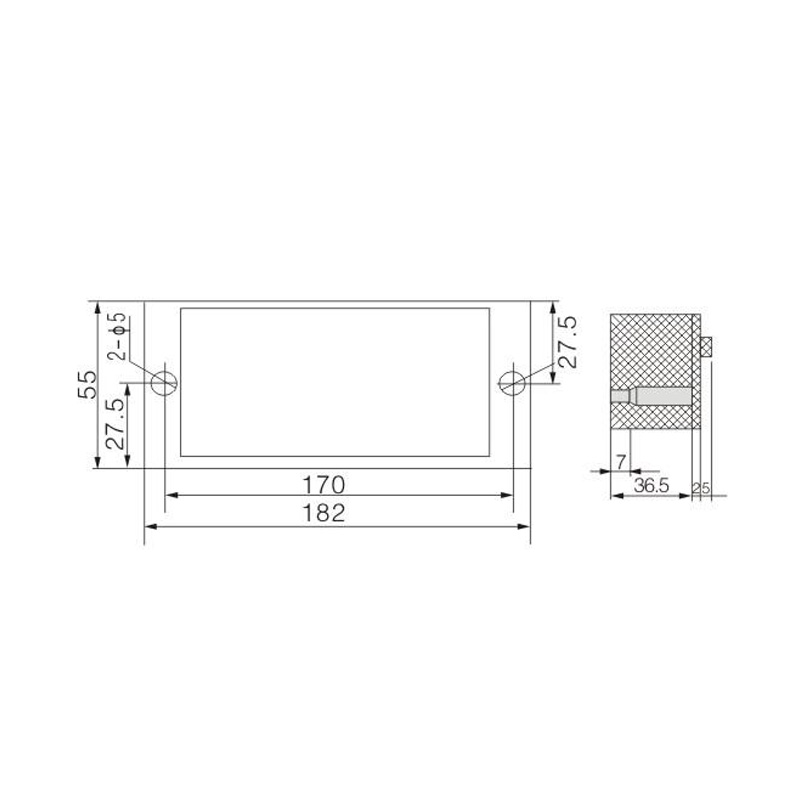

FJ6/JHD-6/C Terminal Blocks for Measuring Box

Model:FJ6/JHD-6/C

Product name: Two-inlet sixteen-outlet(eight-meter household)

Order number: OrderNo.150578

Search

Categories

-

Energy Measuring Terminal Block(314)

- Energy Measuring Joint Terminal Block(16)

- Polycarbonate Energy Measuring Terminal Block(24)

- Standard Wiring Energy Measuring Terminal Block(4)

- Transparent Shell Energy Measuring Terminal Block(6)

- Multifunctional Test Energy Measuring Terminal Block(10)

- Intelligent Safety Energy Measuring Terminal Block(6)

- Single-Phase Multi-Circuit Output Terminal Block(12)

- Self-Elevating Metering Box Terminal Block(7)

- One Household One-Meter Meter Box Dedicated Terminal Block(56)

- Three-Phase Metering Box Dedicated Terminal Block(24)

- Repeatable Grounding Line Terminal Block(20)

- Terminal Block for One-Inlet Multi-Outlet Metering Box(15)

- Closed Terminal Block(11)

- Heavy Current Terminal Block(48)

- Self-Boosting Terminal Block(5)

- Intelligent Self-Locking Terminal Block(3)

- Tool-Free Crimping Type Terminal Block(5)

- Wide Range of Wire Diameters Terminal Block(5)

- Combined Type Energy Measuring Terminal Block(37)

-

Switch Terminal Block(55)

- Pin-Type Incoming Line Switch Terminal Block(4)

- Multi-Way Connection Switch Terminal Block(4)

- Plug-pin Switch Terminal Block(7)

- Combined Type Switch Terminal Block(7)

- High Contact Cross Section Switch Terminal Block(7)

- Wide Range Switch Terminal Block(11)

- One Way in Switch Terminal Block(12)

- Equipped with Circuit Breaker Switch Terminal(3)

-

Heavy-current Terminal Block(631)

- Modular Building Block Terminal Block(156)

- Spherical Non-Destructive Crimp Terminal(120)

- Dual-Mode Connection Electrical Terminal(90)

- Anti-Electricity-Theft Terminal Block(74)

- Convenient Connection Terminal Block(12)

- High-Contact Section Terminal Block(12)

- Wide Range of Wire Diameters Neutral Line Terminal(9)

- Heavy-Current Neutral Line Terminal(9)

- Upper and Lower Rows of Neutral Terminal(2)

- Independent Neutral Line Terminal(7)

- Nose-Type Neutral Line Terminal(7)

- Rail Type Neutral Line Terminal(9)

- Fixed Neutral Line Terminal(12)

- Double Rail Assembly Electrical Terminal(19)

- Blue Jack-Up Terminal(6)

- Black Base Copper Bar Terminal(5)

- Compact Terminal Block(16)

- Precision Terminal Block(23)

- U-Shaped Harpoon Terminal(2)

- Grounding Metering Box Terminal Block(12)

- High-Performance Terminal Block(19)

- Multifunctional Terminal Block(10)

- Din Rail Terminal Block(76)

- Watt-hour Meter Connector(49)

-

Energy Meter Accessories(116)

-

-

Secure connections are essential for reliable electrical distribution, especially when installing a High-performance Terminal Bloc...

READ MORE -

For engineers and panel builders striving for both efficiency and reliability, wiring errors remain a persistent headache — even w...

READ MORE -

In modern electrical systems, a High-performance Terminal Block plays a critical role in ensuring secure and reliable connections ...

READ MORE -

When building or maintaining electrical systems, one frequently overlooked but critical factor is matching the conductor size to t...

READ MORE -

Effective electrical connections depend on more than simply matching cable sizes. Whether you’re securing a power conductor with a...

READ MORE

Intelligent Self-locking Terminal Block: What are its advantages?

The intelligent self-locking terminal block represents a significant leap forward in connection reliability and installer efficiency. Moving beyond the traditional screw clamp, this design incorporates a mechanism, often a spring cage, that automatically locks a inserted wire in place. The advantages of this design are substantial and address several key challenges.

The enhancement of operational safety and connection integrity:The self-locking mechanism applies a constant, predetermined force to the conductor. This force is maintained consistently, unaffected by vibration or thermal cycling, which can cause traditional screw connections to loosen over time. This "vibration-proof" characteristic is crucial in applications like transportation or industrial machinery. It drastically reduces the risk of hot spots, arcing, and eventual connection failure, which are common causes of electrical faults.

Significantly improved installation speed and ergonomics: Installing a wire requires no tools; a technician simply inserts a bare wire directly into the block, where it is locked securely. A standard screwdriver is only needed for release, typically by pressing on a dedicated lever. This tool-less insertion cuts wiring time significantly, reduces installer fatigue, and eliminates the risk of over- or under-tightening screws. The result is a faster, more efficient, and more uniform installation process.

Improve maintenance and troubleshooting efficiency:Their consistent performance means less need for periodic retightening. Furthermore, many designs allow for easy visual inspection to confirm a wire is fully inserted, and the simple release mechanism makes circuit modifications or testing straightforward. By combining a electrical connection with a user-friendly design, intelligent self-locking terminal blocks provide a reliable and cost-effective solution for modern electrical systems.

What are Plug-in Terminal Blocks?

Fundamentally, they consist of two parts: a base that is permanently mounted and wired (often on a DIN rail), and a movable plug unit that contains the second set of contacts.

The primary function of a plug-in terminal block is to create a breakable connection point in a circuit. This design allows for the quick and safe disconnection of a section of equipment without the need to manually unscrew wires. For example, a motor or sensor might be wired to the plug component. If the device needs to be replaced or serviced, a technician simply unplugs it from the mounted base. This isolates the device immediately while leaving the hard-wired connections in the control panel completely undisturbed. This saves considerable time during maintenance and minimizes the risk of wiring errors when reconnecting.

Beyond easy disconnection, these blocks are invaluable for testing and debugging. They create a natural point to insert measurement devices. A technician can unplug a circuit and easily plug in a multimeter or other diagnostic tool to take readings without needing to access the main panel wiring. This simplifies the process of isolating and identifying faults.

The plug and socket mechanism is typically designed with safety in mind, often featuring a locking tab to prevent accidental disconnection due to vibration or pulling. Available in various pole configurations and current ratings, plug-in terminal blocks are a standard feature in control panels for industrial automation, where they connect to drives, I/O modules, and other field devices that require frequent service or replacement.

What are the Smart Terminal Blocks?

Smart terminal blocks are the next evolutionary step, integrating traditional connection functionality with embedded electronics to provide data and control. They move the terminal block from a passive component to an active participant in the system.

1. Integrated Diagnostics and Condition Monitoring:

The core feature of a smart terminal block is its ability to monitor its own status and the health of the connected circuit. This is achieved through embedded sensors and microchips that can continuously measure critical parameters such as current flow, voltage, temperature, and even the state of the connection itself (e.g., wire present/absent). This data is then communicated to a higher-level control system, like a PLC, via a fieldbus protocol (e.g., IO-Link). This allows for predictive maintenance; instead of waiting for a failure, the system can alert operators to a rising temperature or abnormal current draw that indicates a loose connection or impending fault, enabling intervention before downtime occurs.

2. Enhanced Control and Decentralized Intelligence:

Beyond monitoring, smart blocks can incorporate active components. For instance, a smart terminal block can integrate a fuse or a circuit breaker whose status can be communicated digitally. More advanced versions can even include built-in switching functionality, allowing the PLC to remotely control the power output through the terminal block itself. This pushes basic control and diagnostic functions closer to the field devices, enabling a more decentralized and intelligent architecture. This reduces the complexity of the main controller and can simplify overall system wiring by integrating multiple functions—connection, measurement, protection, and control—into a single, compact module on the DIN rail.

English

English Español

Español عربى

عربى