Integrating wired connectivity into the era of automation and digital networking involves more than just traditional hardware. A H...

READ MOREEnergy Measuring Joint Terminal Block Manufacturer

Energy Measuring Joint Terminal Blocks are special terminal blocks applied for standard wiring in energy measuring equipment. They are also suitable for secondary circuits of rated voltage up to 660V and rated current up to 20A. They are used to change of inspect the electric equipment, such as energy meter, electric instrument, and relaying equipment, under on-load circumstances. They can guarantee operational safety and improve.

In order to satisfy customers' demand, our company improves the design and adopts American-imported high-molecular polycarbonate material. It has advantages of high impact resistance, ageing resistance, anti-water absorption, flame retardant, and high temperature resistance. It not only has a bright and elegant appearance, but also has a good product performance. It solves former products' problems, such as fragility, easy mildew stain growth, or heavy CT secondary leakage, easy PT secondary breakdown, etc..This kind of terminal block is an ideal successor to the older generation.

The technical parameters of this product conform to international standards. Feedback from users shows that a new type of this terminal block is capable of preventing missing electric energy measurement. It is helpful for energy measuring work, and can put an end to energy measuring accidents effectively.

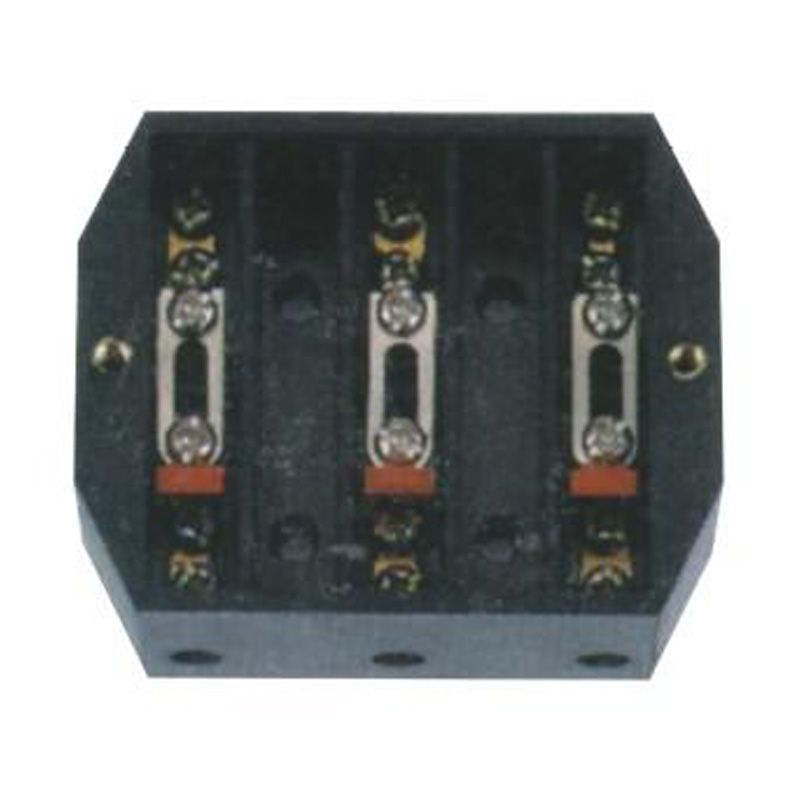

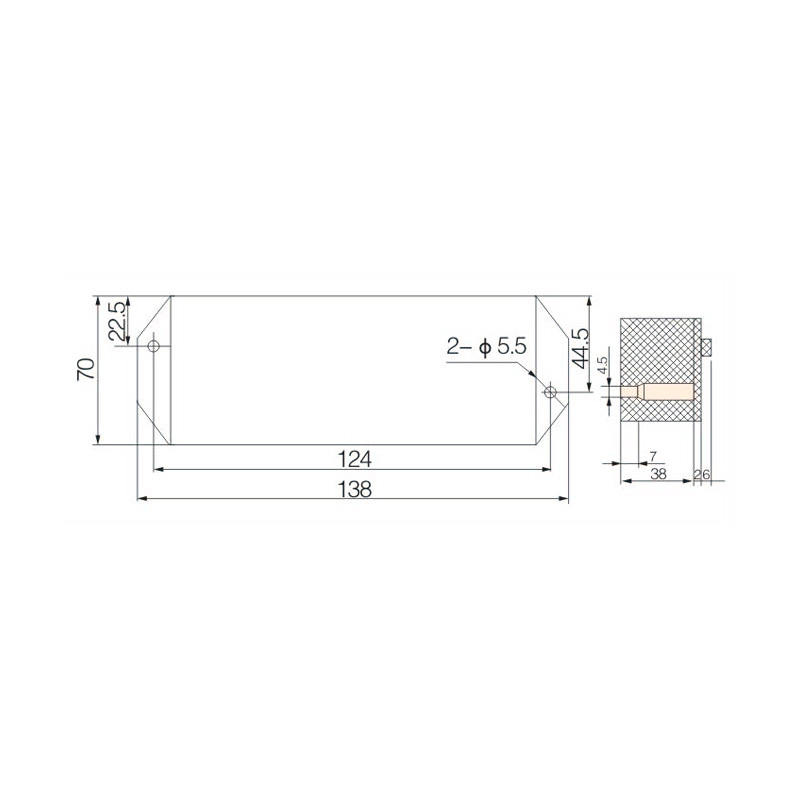

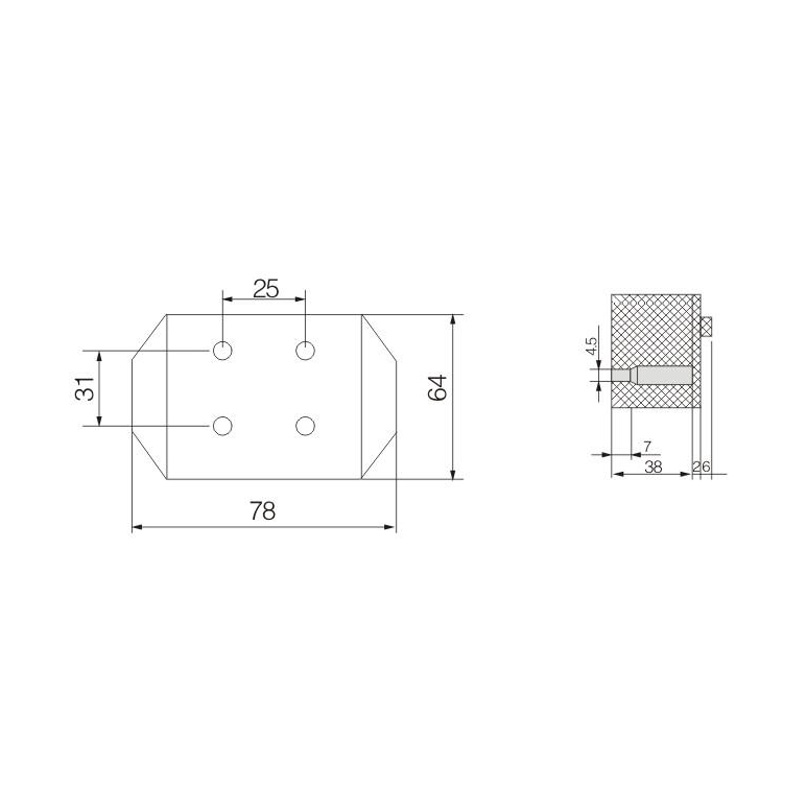

FJ6/DFY2 Bakelite Energy Measuring Terminal Block

Model:FJ6/DFY2 Type (bakelite)

Product name: Three-phase three-wire energy measuring terminal block

Order number: OrderNo.150013

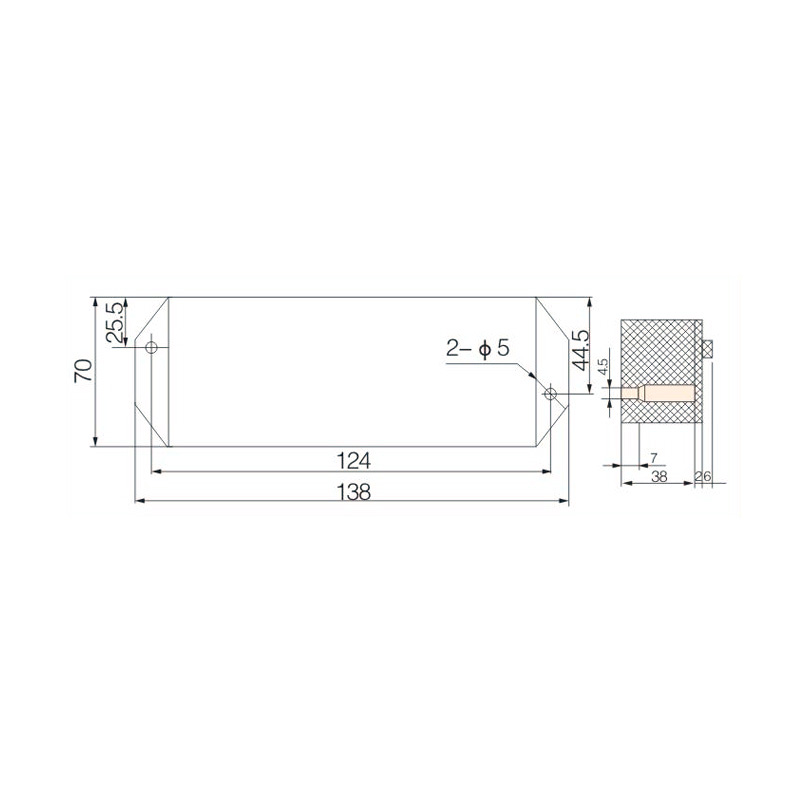

FJ6/DFY2 Bakelite Anti-Electricity Theft Energy Measuring Terminal Block

Model:FJ6/DFY2 Type (bakelite)(anti-electricity theft)

Product name: Three-phase three-wire energy measuring terminal block

Order number: OrderNo.150014

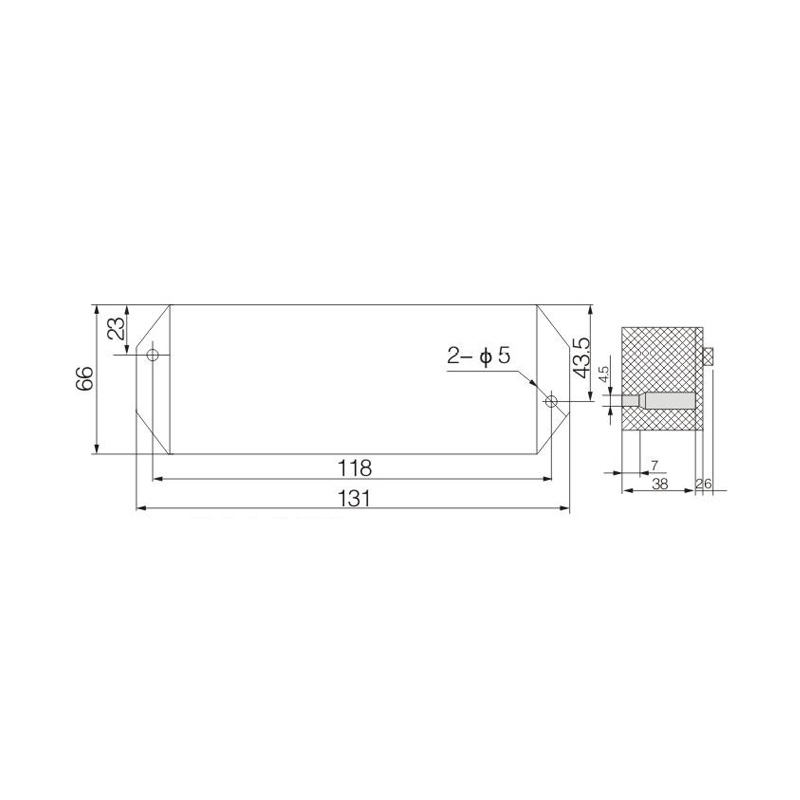

FJ6/DFY2 Fiberglass Resin Anti-Electricity The Theft Energy Measuring Terminal Block

Model:FJ6/DFY2 Type (fiberglass、resin)(anti-electricity the theft)

Product name: Three-phase three-wire energy measuring terminal block

Order number: OrderNo.150015

FJ6Y Energy Measuring Terminal Block

Model:FJ6Y Type

Product name: Three-phase three-wire energy measuring terminal block

Order number: OrderNo.150016

Search

Categories

-

Energy Measuring Terminal Block(314)

- Energy Measuring Joint Terminal Block(16)

- Polycarbonate Energy Measuring Terminal Block(24)

- Standard Wiring Energy Measuring Terminal Block(4)

- Transparent Shell Energy Measuring Terminal Block(6)

- Multifunctional Test Energy Measuring Terminal Block(10)

- Intelligent Safety Energy Measuring Terminal Block(6)

- Single-Phase Multi-Circuit Output Terminal Block(12)

- Self-Elevating Metering Box Terminal Block(7)

- One Household One-Meter Meter Box Dedicated Terminal Block(56)

- Three-Phase Metering Box Dedicated Terminal Block(24)

- Repeatable Grounding Line Terminal Block(20)

- Terminal Block for One-Inlet Multi-Outlet Metering Box(15)

- Closed Terminal Block(11)

- Heavy Current Terminal Block(48)

- Self-Boosting Terminal Block(5)

- Intelligent Self-Locking Terminal Block(3)

- Tool-Free Crimping Type Terminal Block(5)

- Wide Range of Wire Diameters Terminal Block(5)

- Combined Type Energy Measuring Terminal Block(37)

-

Switch Terminal Block(55)

- Pin-Type Incoming Line Switch Terminal Block(4)

- Multi-Way Connection Switch Terminal Block(4)

- Plug-pin Switch Terminal Block(7)

- Combined Type Switch Terminal Block(7)

- High Contact Cross Section Switch Terminal Block(7)

- Wide Range Switch Terminal Block(11)

- One Way in Switch Terminal Block(12)

- Equipped with Circuit Breaker Switch Terminal(3)

-

Heavy-current Terminal Block(631)

- Modular Building Block Terminal Block(156)

- Spherical Non-Destructive Crimp Terminal(120)

- Dual-Mode Connection Electrical Terminal(90)

- Anti-Electricity-Theft Terminal Block(74)

- Convenient Connection Terminal Block(12)

- High-Contact Section Terminal Block(12)

- Wide Range of Wire Diameters Neutral Line Terminal(9)

- Heavy-Current Neutral Line Terminal(9)

- Upper and Lower Rows of Neutral Terminal(2)

- Independent Neutral Line Terminal(7)

- Nose-Type Neutral Line Terminal(7)

- Rail Type Neutral Line Terminal(9)

- Fixed Neutral Line Terminal(12)

- Double Rail Assembly Electrical Terminal(19)

- Blue Jack-Up Terminal(6)

- Black Base Copper Bar Terminal(5)

- Compact Terminal Block(16)

- Precision Terminal Block(23)

- U-Shaped Harpoon Terminal(2)

- Grounding Metering Box Terminal Block(12)

- High-Performance Terminal Block(19)

- Multifunctional Terminal Block(10)

- Din Rail Terminal Block(76)

- Watt-hour Meter Connector(49)

-

Energy Meter Accessories(116)

-

-

Secure connections are essential for reliable electrical distribution, especially when installing a High-performance Terminal Bloc...

READ MORE -

For engineers and panel builders striving for both efficiency and reliability, wiring errors remain a persistent headache — even w...

READ MORE -

In modern electrical systems, a High-performance Terminal Block plays a critical role in ensuring secure and reliable connections ...

READ MORE -

When building or maintaining electrical systems, one frequently overlooked but critical factor is matching the conductor size to t...

READ MORE -

Effective electrical connections depend on more than simply matching cable sizes. Whether you’re securing a power conductor with a...

READ MORE

What Is Safety Certificates For Energy Measuring Joint Terminal Blocks

Energy Measuring Joint Terminal Blocks are designed to ensure secure and reliable connections in electrical systems, especially in energy measurement applications. Safety certificates are essential to guarantee that these components meet industry standards and are safe for use.

1. Role of Safety Certificates

Safety certificates are a testament to the quality and reliability of an Energy Measuring Joint Terminal Block. They provide assurance that the product has undergone rigorous testing and meets specific safety standards. These certificates can include compliance with international standards such as IEC, UL, and CE, which are recognized globally.

2. Importance in the Industry

In the energy sector, the accuracy and safety of measurement equipment are non-negotiable. Safety certificates for Joint Terminal Blocks are crucial for gaining the trust of customers and ensuring compliance with regulatory requirements. They also facilitate international trade by demonstrating that products meet the safety standards of different markets.

3. Types of Certificates

Various certificates can be obtained for Joint Terminal Blocks, including those that certify electrical insulation properties, resistance to environmental factors, and mechanical strength. Each certificate focuses on a specific aspect of safety, ensuring that the product is fit for its intended use.

Manufacturing Process of Wire Joint Connector Terminals: Do You Understand?

Wire Joint Connector Terminals are critical in establishing secure connections in electrical systems. Understanding their manufacturing process provides insight into how these components are made to meet high standards of performance and safety.

1. Material Selection

The manufacturing process begins with selecting the appropriate materials. Materials used for Wire Joint Connector Terminals include copper, brass, and other conductive materials that offer high electrical conductivity and durability.

2. Design and Tooling

Before production, the design of the Wire Joint Connector Terminal is finalized. This involves creating detailed blueprints and developing the necessary tooling for the production process. Precision tooling ensures that each terminal is manufactured to exact specifications.

3. Production Techniques

Wire Joint Connector Terminals are typically produced using processes such as stamping, casting, or machining. Stamping involves using a press to shape the metal into the desired form, while casting involves pouring molten metal into a mold. Machining may be used for more complex designs that require intricate shaping.

4. Quality Control

Throughout the manufacturing process, quality control measures are implemented to ensure that each terminal meets the required standards. This includes inspection for dimensional accuracy, surface finish, and material integrity. Any defects are identified and rectified to maintain product quality.

5. Testing and Certification

Once manufactured, Wire Joint Connector Terminals undergo a series of tests to verify their performance. These tests may include electrical conductivity tests, mechanical strength tests, and environmental resistance tests. Upon passing these tests, terminals receive the necessary safety certifications, ensuring they are safe for use in electrical systems.

Safety certificates for Energy Measuring Joint Terminal Blocks are vital for ensuring the reliability and safety of energy measurement equipment. The manufacturing process of Wire Joint Connector Terminals is a meticulous endeavor that involves material selection, design, production, quality control, and testing. Understanding these aspects is crucial for anyone involved in the electrical industry, as it highlights the importance of precision and safety in the production and use of these critical components.

English

English Español

Español عربى

عربى