Modern electrical control panels often face the challenge of accommodating a growing number of circuits within limited space. Terminal Blocks provide practical solutions for dense wiring applications. By stacking connections vertically or optimizing rail space, these terminal blocks help engineers design compact, organized, and efficient panels. Zhejiang Haidu Electric Co., Ltd. manufactures a variety of dual row terminal blocks and DIN rail terminal blocks to meet the demands of industrial and commercial installations.

1. Benefits of Double-Level Terminal Blocks

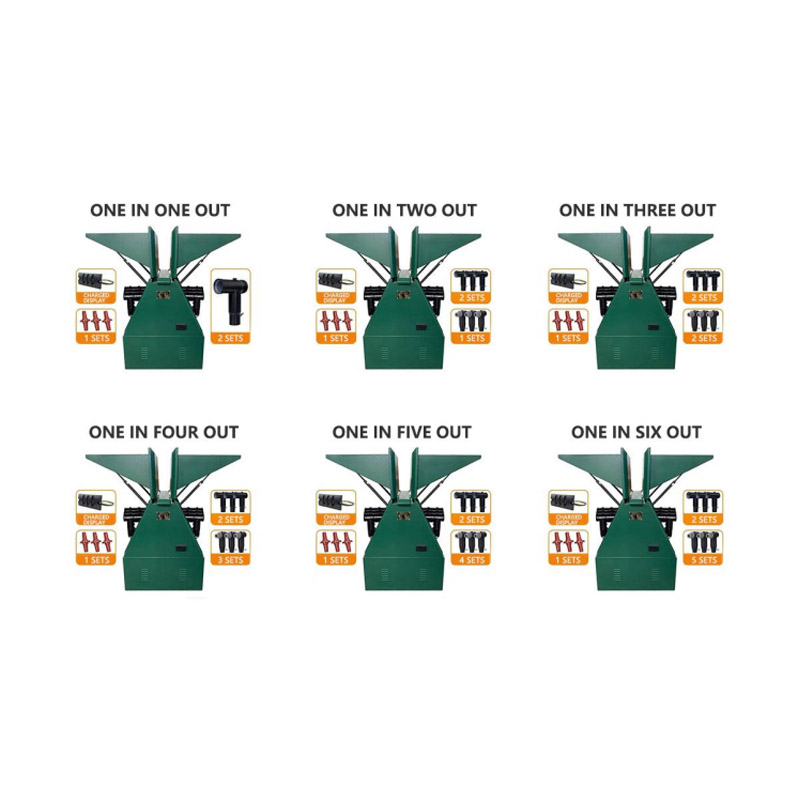

Double-level terminal blocks, also known as dual row or stacked terminal blocks, maximize the number of connections within the same rail length. This design is particularly beneficial for control panels, metering cabinets, and automation systems, allowing engineers to optimize space without compromising accessibility or safety.

Space-saving: Accommodates twice the connections in the same rail length as single-level blocks

Simplified wiring: Reduces the need for crossing wires and messy layouts

Scalable design: Supports future expansions without requiring panel redesign

Enhanced organization: Keeps signal, power, and control wires clearly separated

2. Optimizing Panel Layout

Efficient layout planning is essential for high-density panels. Integrating dual row terminal blocks and DIN rail terminal blocks into the design requires careful consideration of wiring, airflow, and maintenance access:

Vertical stacking: Allows two rows of terminals per rail while maintaining easy access for maintenance and inspections

Wire routing: Use cable ducts, wire guides, or labeling strips to prevent congestion and maintain clear paths

Segmentation of circuits: Group related circuits together to simplify troubleshooting and reduce risk of errors

Panel ventilation: Ensure adequate spacing to allow airflow and prevent heat accumulation

3. Installation Techniques

Correct installation is key to improving the benefits of double-level terminal blocks and ensuring long-term reliability:

Snap-on DIN rail mounting: Securely attach terminal blocks to standard 35mm rails for easy positioning and future modifications

Consistent torque application: Use a torque screwdriver or recommended tool to tighten screws or clamps consistently to prevent loose connections

Wire preparation: Strip insulation accurately and insert wires fully to prevent partial connections, which can cause overheating or intermittent faults

Testing connections: After installation, verify continuity and measure resistance to ensure proper electrical contact

4. Labeling and Identification

In dense wiring environments, clear labeling significantly improves maintenance efficiency and reduces errors:

Numbered terminals: Use printed or engraved numbering for each terminal position

Color-coded wires: Facilitate quick identification of voltage levels, signal types, or functional groups

Marker strips or labels: Maintain clarity even after long-term operation or panel modifications

Documentation: Keep a wiring diagram or panel schematic for reference during troubleshooting or future expansions

5. Electrical and Safety Considerations

High-density wiring requires careful attention to electrical and safety standards:

Current and voltage ratings: Match terminal block specifications to the electrical load of the connected circuits

Insulation and barriers: Dual row terminal blocks often feature barriers between rows to prevent accidental short circuits

Temperature and environmental resistance: Choose terminal blocks that can withstand ambient temperature fluctuations, vibration, and humidity

Material quality: Durable, corrosion-resistant materials ensure long-term safety and reduce maintenance frequency

Zhejiang Haidu Electric Co., Ltd. manufactures terminal blocks designed to meet these stringent requirements, ensuring stable performance and reliable electrical connections.

6. Advantages for Industrial Applications

Industries such as automation, energy distribution, and machinery control benefit significantly from double-level terminal blocks:

Compact panel design: Reduces the required footprint and overall panel size

Simplified maintenance: Organized wiring and clear labeling reduce downtime during troubleshooting

Flexible expansion: Additional circuits can be integrated without major redesign

Cost efficiency: Saves on space, materials, and installation labor

English

English Español

Español عربى

عربى